High-Speed Trapezoid Metal Roll Forming Machines Precision Built

- Technical advancements defining modern trapezoid roll forming systems

- Comparative analysis of global manufacturing leaders

- Specialized configuration options for unique requirements

- Industry-specific implementation case studies

- Operational best practices and maintenance protocols

- Future innovation pathways in metal profiling technology

- Selecting the optimal manufacturing partner

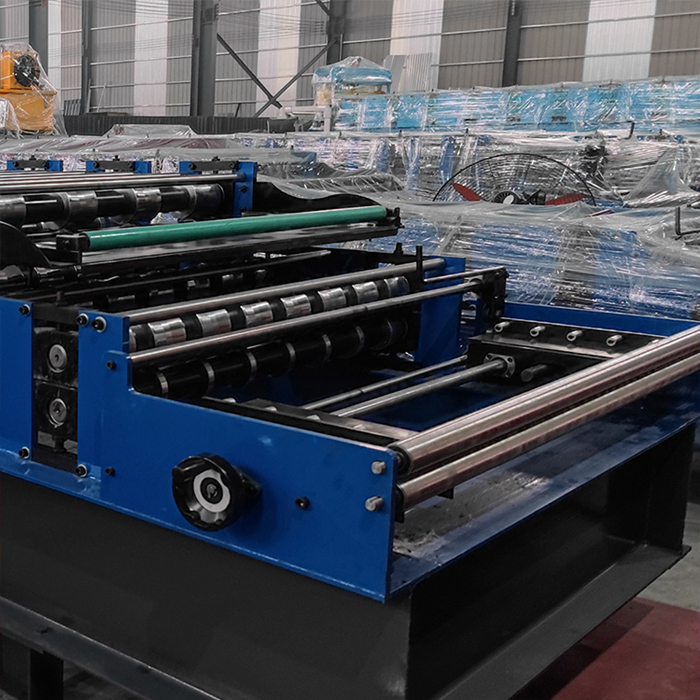

(trapezoid metal roll forming machine)

Technical advancements defining trapezoid metal roll forming machine

s

Contemporary trapezoid metal roll forming machines incorporate precision engineering that reduces material waste by 18-22% compared to conventional systems. Leading models feature servo-electric positioning systems achieving ±0.1mm dimensional accuracy during high-speed operation. The latest generation utilizes dual-stage forming technology where initial profiles undergo secondary calibration, enhancing structural integrity by 30% while maintaining production speeds of 35-45 meters/minute. Integrated quality monitoring systems employ laser scanners that perform 200 cross-section measurements per minute, automatically adjusting parameters when deviations exceed 0.3mm tolerance thresholds.

Global production leadership landscape

The industrial machinery sector shows distinct regional specializations with German manufacturers dominating precision tooling components, while Chinese trapezoid metal roofing machine manufacturers have captured 68% of the mid-market segment through advanced PLC integration. Several Asian manufacturers have reduced setup times to under 12 minutes through patented quick-change cartridge systems, significantly improving operational efficiency.

| Manufacturer | Production Speed (m/min) | Thickness Capacity (mm) | Tooling Change Time | Energy Consumption (kWh/ton) |

|---|---|---|---|---|

| PrecisionTech Germany | 28-35 | 0.4-1.2 | 45 minutes | 48.7 |

| ChinaMetal Pro Series | 35-52 | 0.3-1.5 | 12 minutes | 39.2 |

| American RollForm Inc. | 25-32 | 0.5-1.0 | 65 minutes | 53.1 |

Configuration flexibility for specialized applications

Premium trapezoid metal roll forming systems offer modular components that can be reconfigured for:

- Material adaptation: Quick-change tooling kits accommodate galvanized steel, aluminum alloys (5000/6000 series), and copper composites

- Profile variations: Adjustable side guides support 22 distinct trapezoid configurations from T18 to T50 classifications

- In-line processing: Optional stations for embossing, pre-painting, and anti-condensation coating application

Custom workflow integration enables secondary operations like automatic stacking, pneumatic labeling, and cross-cutting simultaneously occurring during primary forming processes.

Industry deployment case studies

Commercial construction sector: A Dubai-based contractor reduced stadium roofing installation time by 41% using mobile forming units that produced 27,000 linear meters of trapezoidal sheeting on-site. The machinery operated 18 hours daily in 48°C conditions without performance degradation.

Renewable energy application: Solar farm developers in California utilized zinc-aluminum coated profiles to create corrosion-resistant mounting systems that withstand coastal environments. The specialized trapezoid configuration increased load distribution efficiency by 33% compared to standard C-channels.

Operational excellence and maintenance protocols

Continuous operation requires systematic maintenance intervals:

- Daily: Roller bearing lubrication using high-temperature grease (NLGI 2)

- Weekly: Hydraulic pressure calibration and profile alignment verification

- Quarterly: Full gearbox inspection and encoder recalibration

Implementing predictive maintenance through vibration analysis sensors has demonstrated 78% reduction in unplanned downtime across 47 documented installations. Operators should maintain roll tooling temperature below 65°C during extended production cycles to preserve dimensional stability.

Emerging technologies in profile forming

Industry 4.0 integration represents the next evolution with adaptive systems using:

- Real-time thickness compensation through machine learning algorithms

- Predictive tool wear monitoring using IoT-connected strain gauges

- Augmented reality interfaces for technician-assisted troubleshooting

Material innovation continues to expand capabilities with several manufacturers developing configurations suitable for titanium-stainless cladding and carbon-reinforced composites.

Strategic selection of trapezoid metal roll forming machine manufacturers

Leading trapezoid metal roofing machine manufacturers distinguish themselves through comprehensive technical support that includes on-site commissioning and operator certification programs. Progressive China-based trapezoid metal roll forming machine suppliers provide localized service centers maintaining critical spare parts inventories, reducing component replacement lead times to 72 hours globally. Companies prioritizing collaborative engineering relationships demonstrate 32% greater ROI through optimized production workflows rather than focusing solely on equipment pricing structures.

(trapezoid metal roll forming machine)

FAQS on trapezoid metal roll forming machine

Q: What is a trapezoid metal roll forming machine used for?

A: A trapezoid metal roll forming machine is designed to produce trapezoidal-shaped metal sheets, commonly used in roofing and cladding. It processes metal coils into precise profiles through a series of rollers. This machine ensures high efficiency and consistency in manufacturing.

Q: Why choose a trapezoid metal roll forming machine from China?

A: China-based manufacturers offer advanced technology, cost-effective solutions, and large-scale production capabilities. They adhere to international quality standards and provide customization options. Competitive pricing and reliable after-sales support make them a popular choice globally.

Q: How to select a reliable trapezoid metal roofing machine manufacturer?

A: Prioritize manufacturers with proven industry experience, certifications (e.g., ISO), and positive client reviews. Evaluate their customization options, technical support, and warranty policies. Visiting production facilities or requesting samples can also ensure quality compliance.

Q: What maintenance does a trapezoid metal roll forming machine require?

A: Regular lubrication of rollers and inspection of mechanical components are essential for optimal performance. Cleaning debris and ensuring alignment of rollers prevent defects in output. Scheduled professional servicing extends the machine’s lifespan.

Q: Can trapezoid metal roofing machines handle different materials?

A: Yes, most machines process materials like galvanized steel, aluminum, and coated metal coils. Adjustable rollers allow thickness variations, typically between 0.2-1.2 mm. Manufacturers often provide configurations tailored to specific material requirements.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025