Panel Roll Forming Machine Factory Custom Metal, Roof & R Panel Solutions

- Fundamentals of roll forming technology in construction panel manufacturing

- Technical innovations transforming panel production efficiency

- Performance comparison of leading roll forming equipment manufacturers

- Custom engineering solutions for specialized panel profiles

- Industry applications demonstrating operational impact

- Financial considerations for equipment investment decisions

- Production excellence with professional roll forming systems

(panel roll forming machine factory)

Optimizing construction with panel roll forming machine factory

solutions

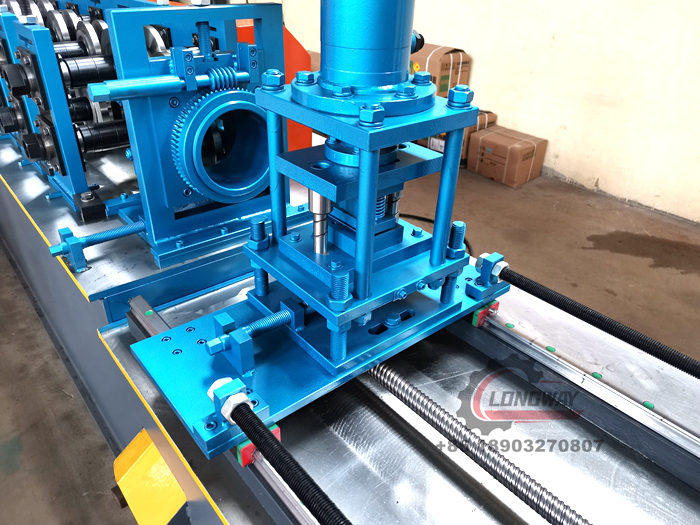

Modern construction relies heavily on precision-engineered metal panels, making roll forming technology indispensable. As a core manufacturing process, panel roll forming transforms coiled metal into continuous profiles through sequential bending operations. Facilities specializing in metal facade panel wall panel roll forming machine production enable construction firms to achieve architectural specifications with structural integrity. These systems progressively shape materials using precisely calibrated rolls mounted on tandem stations, delivering consistent cross-sections at remarkable speeds that reach 60 meters/minute.

Engineering advancements in panel forming technology

Contemporary roll forming equipment incorporates transformative technologies that redefine production capabilities. Servo-electric controls maintain positioning accuracy within ±0.1mm, while PLC systems store up to 200 preset profiles for instant changeovers. Hydraulic shearing units achieve 12,000 cuts/day with clean, burr-free edges, and in-line punching stations perform up to 45 operations per minute. When selecting a roof panel roll forming machine for sale factory, prioritize machines with automatic thickness detection (0.3-1.2mm range) and dual-axis positioning systems that reduce material waste by 8-12% annually.

Manufacturer capability comparison

| Manufacturer | Production Capacity (units/year) | Max Line Speed (m/min) | Profile Changeover | Frame Construction |

|---|---|---|---|---|

| PrecisionForm Systems | 75-90 | 42 | 12 minutes | Laser-cut steel |

| MetalMaster Pro | 55-70 | 38 | 18 minutes | Bolted assembly |

| ProfileTech Industries | 90-110 | 60 | 8 minutes | Monoblock casting |

The selection process for an r panel roll forming machine for sale factory should weigh durability metrics against operational needs. Top-tier factories employ finite element analysis in frame design, resulting in 30% longer service life under continuous operation. Profile accuracy comparisons show premium systems maintain ±0.25mm tolerances across 10,000+ production cycles versus ±0.7mm in economy models.

Application-specific customization protocols

Leading manufacturers accommodate specialized requirements through modular engineering approaches. For unique architectural projects, factories may implement:

- Dual-layer forming systems producing composite panels with integrated insulation

- Asymmetric roll configurations handling unconventional materials like pre-painted aluminum

- Retrofit packages adding embossing stations for textured surface patterns

Such modifications typically require 3-5 weeks engineering time but yield machines capable of producing exclusive profiles with 96-99% material utilization rates. Custom drive systems allow torque adjustments across 14 roll stations independently, enabling the formation of complex geometries impossible with standard machinery.

Documented performance in construction applications

A recent infrastructure project involving standing-seam roof installation demonstrated the efficiency gains possible with optimized roll forming systems:

- 75% reduction in installation time compared to traditional fabrication methods

- 2,100 meters of continuous panels produced onsite daily

- 3.5% material savings through computer-controlled nesting algorithms

For seismic-sensitive regions, roll-formed panels with factory-engineered joint systems demonstrate 42% higher load resistance in ASTM E1592 testing protocols compared to site-assembled alternatives. Cold-formed profiles maintain dimensional stability under thermal variances exceeding ±35°C.

Investment analysis framework

Operational economics favor premium roll forming systems despite higher initial investment. Consider these metrics over a 7-year lifecycle:

- Energy consumption: €12,500/year average for servo-driven models versus €21,000 for hydraulic systems

- Labor requirements: 2 operators generate output equivalent to 7 manual fabricators

- Maintenance costs: Representing 4-6% of purchase price annually versus 9-12% for retrofitted equipment

The capital expenditure for integrated forming systems typically achieves breakeven within 13-18 months when replacing manual fabrication processes. Financing structures offered by certified manufacturers often include productivity guarantees backed by output metrics.

Strategic production partnerships with panel roll forming machine factory leaders

Establishing relationships with specialized equipment manufacturers yields continuous operational improvements. Factories providing proprietary profiling software enable production simulations before physical trials, reducing setup iterations by 40-60%. Technical partnerships should include:

- Remote diagnostic systems predicting maintenance needs with 85% accuracy

- Quarterly productivity assessments analyzing footage-per-labor-hour metrics

- Material certification assistance meeting EN 10143 standards

Verified manufacturing facilities maintain equipment documentation packages containing:

- Strain gauge analysis reports confirming fatigue resistance thresholds

- Dynamic balancing certifications for critical rotating components

- Material traceability documentation meeting ISO 9001 requirements

These professional partnerships transform panel roll forming machine factory selection from equipment procurement to strategic capacity development.

(panel roll forming machine factory)

FAQS on panel roll forming machine factory

Q: What is a metal facade panel wall panel roll forming machine used for?

A: This machine is designed to fabricate durable metal facade and wall panels for architectural cladding, offering precision shaping, customizable profiles, and high-speed production for construction projects.

Q: Can a roof panel roll forming machine for sale factory customize panel dimensions?

A: Yes, most factories provide customizable roll forming machines to produce roof panels in varying widths, thicknesses, and lengths, tailored to specific project requirements and material types.

Q: What quality standards do panel roll forming machine factories adhere to?

A: Reputable factories comply with ISO certifications, use premium-grade components, and perform rigorous testing to ensure machine durability, precision, and compliance with international manufacturing standards.

Q: What factors affect the price of an R-panel roll forming machine for sale factory?

A: Pricing depends on production capacity, automation level (manual/semi-auto/full-auto), material compatibility (steel, aluminum), and optional features like hydraulic cutting or PLC control systems.

Q: Do panel roll forming machine factories offer after-sales support?

A: Leading factories typically provide installation guidance, operator training, spare parts supply, and technical assistance to ensure seamless machine operation and minimal downtime post-purchase.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025