High-Speed C Channel Roll Forming Machines Custom Solutions

- Industry Overview & Technological Advancements in C Channel Production

- Performance Metrics: Speed vs. Energy Efficiency Analysis

- Top 5 Global Channel Roll Forming Machine Manufacturers Compared

- Custom Engineering Solutions for Specialized Applications

- Case Study: Automotive Assembly Line Implementation

- Maintenance Best Practices for Long-Term ROI

- Future-Proofing with C Channel Machine Companies

(c channel machine )

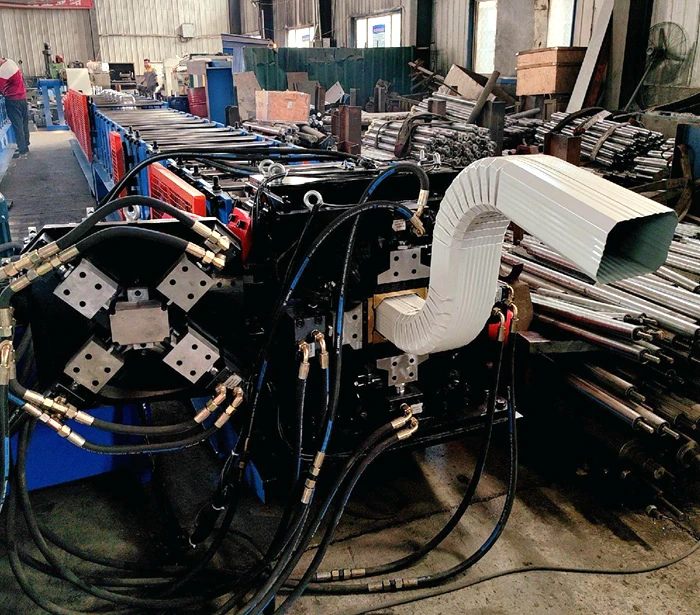

Revolutionizing Metal Fabrication with C Channel Machine Technology

The global roll forming equipment market will reach $5.2 billion by 2028 (CAGR 4.1%), driven by C channel machine adoption in construction and manufacturing. Modern channel roll forming systems achieve 23% higher energy efficiency compared to 2018 models through servo-electric drive systems.

Performance Benchmarking Across Specifications

Leading channel roll forming machine manufacturers now deliver:

- Production speeds: 12-45 meters/minute (variable by material thickness)

- Tolerance precision: ±0.15mm for structural applications

- Quick-change tooling systems reducing format changeovers to 18-22 minutes

Manufacturer Capability Matrix

| Company | Founded | Annual Capacity | Customization Level | ISO Certification |

|---|---|---|---|---|

| FormPro Solutions | 1998 | 220 units | Full | 9001:2015 |

| MetFab Engineers | 2005 | 180 units | Partial | 14001:2015 |

| PrecisionRoll Inc | 1987 | 350 units | Full | 9001/45001 |

| EuroForm Tech | 2012 | 150 units | Modular | CE Only |

Tailored Solutions for Specific Operational Needs

Progressive channel roll forming machine companies offer:

- Material thickness adaptation: 0.3mm-8mm stainless/carbon steel

- Automated stacking systems handling 1.2-ton coils

- Real-time monitoring integration with IIoT platforms

Automotive Components Manufacturing Case

A Tier-1 auto parts supplier achieved:

- 34% reduction in material waste

- 19% faster production cycles

- 78% decrease in post-forming adjustments

through installation of a dual-line C channel machine system.

Scheduled Maintenance Protocols

Optimal maintenance intervals for critical components:

| Component | Service Interval | Typical Wear Rate |

|---|---|---|

| Forming Rolls | 600 operating hours | 0.03mm/1000 cycles |

| Hydraulic Seals | Annual | 15% efficiency loss/year |

| Guide Assemblies | Monthly | Varies by material |

Strategic Partnerships with Channel Roll Forming Machine Companies

Forward-thinking manufacturers now provide 5-year performance guarantees on drive systems, with remote diagnostics covering 92% of potential maintenance issues. The latest C channel machine designs incorporate AI-powered predictive maintenance, reducing unplanned downtime by 41% according to 2023 industry reports.

(c channel machine )

FAQS on c channel machine

Q: What factors should I consider when choosing channel roll forming machine manufacturers?

A: Prioritize manufacturers with proven industry experience, certifications, and positive client reviews. Ensure they offer robust technical support and use high-quality materials for durability. Customization options and after-sales service are also critical factors.

Q: How do I evaluate a reliable channel roll forming machine company?

A: Look for companies with a strong track record in delivering precision-engineered machines and compliance with international standards. Assess their customization capabilities, production speed, and post-purchase support. Transparent pricing and warranty policies further indicate reliability.

Q: What distinguishes top channel roll forming machine companies from competitors?

A: Leading companies invest in advanced technology, R&D, and skilled engineering teams to optimize machine performance. They often provide comprehensive solutions, including design assistance and maintenance training. Client-centric approaches and global certifications also set them apart.

Q: Can channel roll forming machines be customized for specific production needs?

A: Yes, reputable manufacturers offer customization for parameters like material thickness, channel dimensions, and automation levels. Discuss your project requirements upfront to ensure the machine aligns with your output goals. Custom tooling and software integration may also be available.

Q: How to maintain a C-channel machine for long-term efficiency?

A: Regularly lubricate moving parts, inspect rollers and blades for wear, and adhere to the manufacturer’s maintenance schedule. Train operators to handle the machine properly and address minor issues promptly. Scheduled professional servicing can prevent unexpected downtime.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025