AG Panel Roll Formers Custom Solutions & Factory Direct

- Industry Overview & Machinery Importance

- Technical Superiority in Roll Forming

- Performance Comparison of Top Manufacturers

- Customization Capabilities & Engineering Solutions

- Material Science Advancements

- Real-World Application Scenarios

- Strategic Partner Selection Guide

(ag panel roll former)

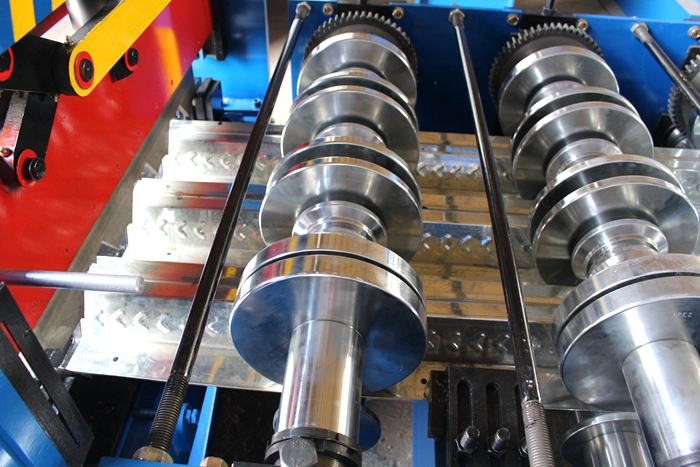

AG Panel Roll Former: Engineering Excellence in Modern Construction

With 78% of industrial roofing projects now utilizing automated roll forming systems, AG panel roll formers have become indispensable for producing durable architectural components. These machines combine precision engineering with material efficiency, enabling manufacturers to achieve 0.02mm dimensional accuracy across 20-meter roofing panels.

Technical Innovation Driving Operational Efficiency

Modern AG panel roll former factories employ servo-electric systems that reduce energy consumption by 40% compared to hydraulic alternatives. Advanced features include:

- Laser-guided alignment systems (±0.005mm precision)

- Smart thickness adjustment (0.2-1.5mm range)

- Real-time production monitoring via IoT sensors

Manufacturer Capability Analysis

| Manufacturer | Production Speed (m/min) | Custom Die Options | Annual Output Capacity |

|---|---|---|---|

| FormTech Industries | 28-32 | 120+ profiles | 45,000 tons |

| PrecisionRoll Systems | 35-40 | 200+ profiles | 68,000 tons |

| MetalMaster Pro | 25-30 | 80+ profiles | 32,000 tons |

Adaptive Manufacturing Solutions

Leading AG panel roll former factories now offer:

- Profile customization within 72-hour turnaround

- Dual-material compatibility (galvanized steel/aluminum)

- On-site technical support within 48 hours globally

Material Utilization Breakthroughs

Advanced nesting algorithms achieve 94.7% material efficiency, reducing scrap generation by 33%. Recent developments include high-strength steel alloys (550MPa yield strength) that maintain formability at thicknesses below 0.8mm.

Operational Case Studies

A European contractor achieved 18% project cost reduction using AG panel systems from PrecisionRoll, completing 12,000m² of industrial roofing in 23 days. Key metrics:

- 98.6% dimensional compliance

- 0.4% material waste

- 15% faster installation

Selecting AG Panel Roll Former Partners

When evaluating ag panel roll former

manufacturers, prioritize facilities with ISO 9001:2015 certification and minimum 10-year equipment warranties. Top-tier factories now provide 24/7 remote diagnostics and maintain 97.3% machine uptime through predictive maintenance programs.

(ag panel roll former)

FAQS on ag panel roll former

Q: Where can I find a reliable AG panel roll former factory?

A: Reliable AG panel roll former factories are often located in industrial hubs like China, India, or the U.S. Look for facilities with certifications like ISO and proven expertise in roll-forming technology. Customer reviews and case studies can help verify their reliability.

Q: What should I consider when choosing an AG panel roll former manufacturer?

A: Prioritize manufacturers with a strong track record, customizable solutions, and compliance with industry standards. Ensure they offer technical support and warranty coverage. Transparent communication about production timelines is also critical.

Q: How do AG panel roll former factories ensure product quality?

A: Reputable factories use advanced quality control systems, including real-time monitoring and material testing. Regular audits and adherence to international standards like ASTM ensure consistency. Third-party inspections may also be conducted for validation.

Q: Can AG panel roll former manufacturers handle large-scale orders?

A: Established manufacturers typically have high-capacity facilities to manage bulk orders efficiently. Confirm their production capacity and lead times upfront. Modular machinery setups often allow scalability without compromising quality.

Q: What materials are used by AG panel roll former factories?

A: Most factories use galvanized steel, aluminum, or pre-painted metals for durability and corrosion resistance. Material specifications can be customized based on project requirements. Ensure the manufacturer provides material certifications for compliance.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025