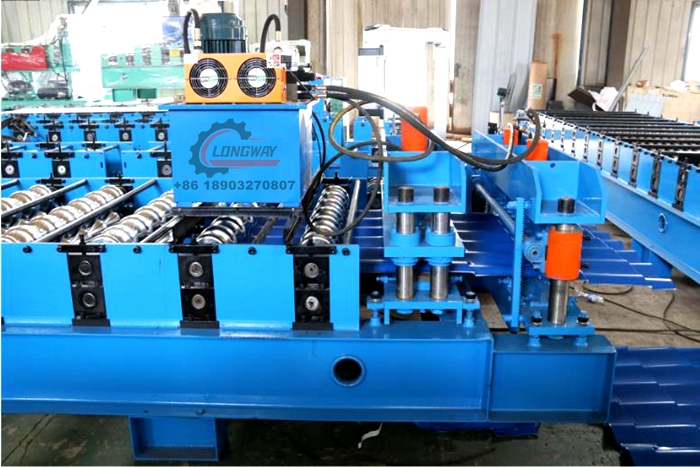

Euro 1100 Metal Roof Tile Making Machine - Fast & Precise?

A Field Report: Why the Euro 1100 Metal roof tile making machine is popping up in serious roofing shops

I’ve toured more than a few roll-forming lines in the last decade, from tight little workshops to cavernous export plants in Hebei. This model, born in SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE, has been drawing murmurs—good ones—especially from contractors chasing Euro-style profiles without babysitting the line all day.

What’s trending in metal tile forming

Two big shifts: thinner coated coils (to keep costs sane) and tighter profile tolerances (architects are picky, to be honest). Automation is creeping in, but not everyone wants a fully robotic cell. This line hits a middle ground—robust mechanics, simple HMI, and a hydraulic press that doesn’t smudge the paint. Many customers say the setup time is refreshingly short.

Core specs at a glance

| Effective tile cover width | ≈1100 mm (real-world may vary by profile) |

| Raw materials | PPGI/PPGL/GI, 0.3–0.6 mm; yield strength 235–550 MPa |

| Forming speed | 2–4 m/min (step-tile mode); up to ≈8 m/min in straight run |

| Stations & shafts | 15–18 stations; Ø70 mm shafts (≈) |

| Roller material | 45# steel, quenched & hard-chrome plated; optional GCr15 |

| Cut/press | Hydraulic post-cut; step embossing die with anti-mark pads |

| Drive & power | Chain drive; main motor ≈7.5–11 kW; hydraulic unit ≈4 kW |

| Warranty | 2 Years Free Warranty |

Process flow, testing, and standards

Euro 1100 Metal roof tile making machine workflow: decoiler → leveling → roll forming → hydraulic step pressing → length cutting → runout table/stacker. Materials are typically pre-painted coils complying with ASTM A653 or EN 10346. Dimensional checks show ±0.5 mm on width and ±1.0 mm on step pitch in regular production, and noise keeps under ≈75 dB at 1 m—better than I expected.

- Coating durability verified per EN 13523 (adhesion often cross-checked by ASTM D3359).

- CE-conform design referencing EU Machinery Directive 2006/42/EC.

- Factory QMS typically aligned with ISO 9001; batch traceability is improving, I noticed.

- Service life: frame/mechanics 10–15 years; dies may need re-lapping around year 5–7 depending on throughput.

Where it fits

Applications: residential villas, tourism projects, coastal resorts (PPGL helps), schools and stadium roofs. Industries using it range from regional roofing manufacturers to EPC contractors who prefer in-house tile production to dodge shipping delays.

Vendor comparison (quick take)

| Vendor | Notable strengths | Considerations |

|---|---|---|

| LW (Cangzhou) | Stable hydraulics; clean press marks; responsive after-sales; 2-year warranty | Lead times spike in Q3; book early |

| Vendor A (North China) | Aggressive pricing; quick ship on standard profiles | Roller chrome sometimes thinner; watch wear rate |

| Vendor B (Coastal) | High automation options; remote diagnostics | Upsells can balloon total cost |

Customization and options

- Profile tweaks: step height, wave pitch, anti-capillary grooves.

- Hydraulic decoiler (5T/7T/10T) with coil car; or manual for budget builds.

- Servo step feeding to tighten pitch tolerance to ≈±0.5 mm.

- Embossing textures for premium tiles; PU film applicator to protect gloss.

Real-world notes and a mini case

One Polish roofer told me output settled around 3.2 m/min with 0.5 mm PPGL, 8-hour shifts, and less than 1.5% scrap (mostly starter/ender pieces). Another buyer in Kenya liked the simple HMI—training two operators in half a day, which, frankly, is rare. Euro 1100 Metal roof tile making machine doesn’t chase glitz; it’s more “show up and run.”

Quality and support

Factory FAT includes dry run, coil test, and profile checks against drawings. Spare kits usually cover seals, blades, and sensor spares for 6–12 months. With the 2-year warranty, you’re covered for critical parts; consumables, obviously, are on you.

Citations

- EU Machinery Directive 2006/42/EC – EUR-Lex.

- ISO 9001:2015 Quality management systems – Requirements, ISO.

- EN 13523 series – Coil coated metals, Test methods (adhesion, impact, etc.).

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025