Precision Metal Steel Plate Embossing Machine | Custom Patterns

Industry Trends in Metal Plate Embossing Technology

The global manufacturing sector is witnessing a significant shift towards enhanced automation, precision, and material efficiency. In this landscape, the demand for sophisticated metal processing machinery is escalating, particularly for solutions that offer both aesthetic versatility and structural integrity. The Metal Steel Plate Embossing Machine stands at the forefront of this evolution, driven by its ability to impart unique patterns and textures onto various metal surfaces. Current industry trends highlight a growing need for machines capable of handling diverse metal types, including carbon steel, stainless steel, aluminum, and copper, with increased speed and reduced energy consumption. Furthermore, there's a strong emphasis on smart manufacturing integration, predictive maintenance capabilities, and advanced human-machine interfaces (HMIs) to optimize operational efficiency and reduce downtime.

Sustainable manufacturing practices are also shaping the market, with a preference for machinery designed for minimal material waste and energy-efficient operations. The pursuit of custom and complex designs for architectural, automotive, and industrial applications is pushing the boundaries of embossing technology, requiring machines with higher tonnage capacities, advanced hydraulic or servo-electric systems, and precise die alignment. These machines are pivotal in creating non-slip surfaces, decorative panels, and structural components with improved rigidity-to-weight ratios, thereby contributing to both functional and aesthetic aspects of modern engineering and design.

Detailed Manufacturing Process Flow of a Metal Embossing Machine

The production of a high-performance Metal Steel Plate Embossing Machine involves a meticulously engineered process, ensuring durability, precision, and operational excellence. Adherence to stringent quality control throughout each stage is paramount, guaranteeing the machine's reliability and extended service life, often exceeding 15-20 years with proper maintenance.

- Material Selection and Preparation: High-grade structural steel (e.g., Q235, Q345) and alloy steel are chosen for the main frame, rollers, and critical components to ensure robustness and resistance to deformation under high pressure. Hydraulic cylinders utilize precision-honed steel tubes and chrome-plated piston rods. Materials undergo spectrographic analysis to verify chemical composition and mechanical properties.

- Primary Fabrication (Casting/Forging): Large structural components like machine bases and frames are often cast from high-strength iron or steel alloys to achieve optimal rigidity. Roller blanks are forged from tool steel (e.g., Cr12MoV) or alloy steel (e.g., 42CrMo) to enhance grain structure and wear resistance. These processes are critical for the foundational strength of the machine.

- Precision CNC Machining: After casting or forging, components undergo extensive CNC machining. This includes milling, turning, boring, and grinding to achieve precise dimensions and tight tolerances. Critical surfaces, such as those for roller mounting and hydraulic cylinder seating, are machined to micron-level accuracy. This phase is crucial for the operational precision and alignment of the embossing mechanism.

- Heat Treatment: Rollers, gears, and other wear-prone parts are subjected to advanced heat treatment processes, such as quenching and tempering, carburizing, or nitriding. This significantly increases their surface hardness (e.g., HRC 58-62 for rollers) and fatigue resistance, extending their operational lifespan and maintaining pattern fidelity.

- Surface Treatment and Coating: Components are treated for corrosion resistance. This may involve shot blasting, priming, and multiple layers of industrial-grade paint or specialized coatings to protect against harsh industrial environments, particularly relevant for target industries like petrochemicals and metallurgy.

- Assembly: Highly skilled technicians meticulously assemble the machine, integrating mechanical, hydraulic, and electrical systems. This includes precise alignment of rollers, installation of hydraulic pumps and cylinders, and wiring of control panels. Every connection and joint is torqued to specification.

- Electrical and Control System Integration: PLC-based control systems, often from reputable brands like Siemens or Rockwell, are integrated. HMI touchscreens are calibrated, and safety interlocks are verified to ensure seamless operation and operator safety.

- Testing and Quality Assurance: Each Metal Steel Plate Embossing Machine undergoes rigorous functional testing. This includes no-load and full-load testing, hydraulic pressure checks, electrical system verification, and an embossing performance test with various material thicknesses. All critical dimensions and operational parameters are measured against design specifications. Compliance with international standards such as ISO 9001 for quality management and CE marking for safety is verified. Materials are often tested against ASTM or DIN standards.

- Final Inspection and Documentation: A comprehensive final inspection covers all aspects from aesthetics to performance. Detailed operational manuals, maintenance guides, and spare parts lists are compiled.

Advantages in Typical Application Scenarios:

- Energy Saving: Modern hydraulic systems with variable frequency drives (VFDs) and servo pumps reduce energy consumption by up to 30% compared to traditional constant-speed pumps, by only drawing power on demand.

- Corrosion Resistance: Machines designed for industries like petrochemical and water supply & drainage feature components with enhanced surface treatments and specialized coatings, ensuring longevity in corrosive environments. For example, hydraulic lines might be stainless steel, and exterior panels powder-coated.

- Enhanced Safety: Integrated safety light curtains, emergency stop buttons, and robust guarding mechanisms protect operators, meeting ANSI B11.2 standards for hydraulic power presses.

Technical Specifications and Parameters

Understanding the precise technical parameters is crucial for selecting the right Metal Steel Plate Embossing Machine for specific industrial requirements. Our machines are engineered for optimal performance, ensuring consistency and efficiency in production. Below is a detailed table outlining typical specifications for our standard models.

| Parameter | Value Range (Typical) | Description |

|---|---|---|

| Plate Material Thickness | 0.5 mm - 6.0 mm | Capacity to emboss various gauges of steel, aluminum, etc. |

| Max Plate Width | Up to 2000 mm | Accommodates a wide range of sheet sizes for diverse applications. |

| Embossing Speed | 5 - 15 m/min | Adjustable speed for optimal production rates and pattern detail. |

| Roller Diameter | Ø 300 mm - Ø 600 mm | Impacts embossing depth and pattern fidelity; hardened and ground. |

| Motor Power (Main) | 37 kW - 90 kW | High-efficiency motor for consistent power delivery during operation. |

| Hydraulic System Pressure | 16 MPa - 25 MPa | Ensures sufficient force for deep and precise embossing patterns. |

| Control System | PLC with HMI Touchscreen | User-friendly interface for parameter adjustment and monitoring. |

| Machine Dimensions (L x W x H) | Approx. 4m x 2.5m x 2m | Varies by model and capacity; designed for industrial environments. |

| Net Weight | 8,000 kg - 25,000 kg | Heavy-duty construction for stability and vibration reduction. |

These specifications are indicative of the robust engineering and high-capacity design of our machines. Each component is selected and manufactured to meet rigorous industrial standards, ensuring long-term reliability and minimal maintenance requirements. Our designs prioritize ease of integration into existing production lines and operator safety.

Application Scenarios and Target Industries

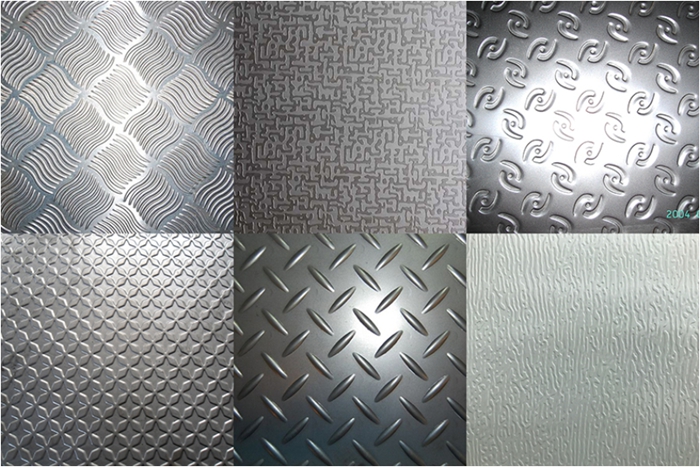

The versatility of the Metal Steel Plate Embossing Machine makes it indispensable across a spectrum of industries, providing both functional enhancements and aesthetic value to metal products. Its ability to create various patterns – from classic diamond plate and stucco to custom geometric designs – opens up numerous possibilities.

Key Target Industries:

- Petrochemical Industry: Embossed metal plates are widely used for anti-slip flooring, walkways, stair treads, and platform grating in oil refineries, chemical plants, and offshore platforms. The raised patterns significantly improve traction, reducing occupational hazards in oily or wet environments.

- Metallurgy and Heavy Manufacturing: Used for creating durable, anti-skid surfaces on machinery access panels, heavy equipment components, and industrial vehicle floors. Also employed for decorative finishes on structural steel elements.

- Water Supply & Drainage Systems: Embossed plates find application in pump stations, treatment plants, and utility access covers where corrosion resistance and non-slip properties are crucial for safety and longevity.

- Automotive Sector: For truck bed liners, utility vehicle flooring, bus interiors, and decorative trim, providing both aesthetic appeal and functional durability.

- Construction and Architecture: Used for creating visually appealing facade panels, interior wall cladding, ceiling tiles, and decorative elements that also offer increased rigidity and impact resistance. Staircases, ramps, and platforms in public spaces benefit from enhanced slip resistance.

- Logistics and Warehousing: Flooring for loading docks, pallet racks, and industrial trolleys where slip prevention and wear resistance are paramount.

The ability to emboss various metals like mild steel, stainless steel (e.g., 304, 316), and aluminum alloys extends the application range of these machines, providing solutions that meet stringent industry standards for safety, durability, and aesthetics.

Technical Advantages of Our Metal Steel Plate Embossing Machine

Our Metal Steel Plate Embossing Machine offers a suite of advanced technical advantages designed to deliver superior performance, reliability, and cost-efficiency for our B2B clients. These benefits stem from meticulous engineering and a deep understanding of industrial demands.

- High Precision Embossing: Equipped with hardened alloy steel rollers and a robust frame, our machines ensure consistent pattern depth and crisp details across the entire sheet, even at high speeds. Precision planetary gearboxes and advanced bearing systems minimize backlash and maintain roller alignment.

- Advanced Hydraulic System: Features a high-pressure, closed-loop hydraulic system with proportional valves for precise control over embossing force and speed. This dynamic control reduces material stress and prevents cracking, especially for thicker or harder materials. Integrated cooling systems ensure optimal hydraulic fluid temperature, extending component life.

- Robust Construction for Durability: The machine frame is fabricated from heavy-duty welded steel, stress-relieved to prevent deformation. Critical wear parts, like rollers and gears, are made from special tool steel and undergo multiple stages of heat treatment and precision grinding, ensuring exceptional hardness and resistance to abrasive wear over decades of operation.

- Intelligent PLC Control with HMI: Integrated with industry-leading PLCs (e.g., Siemens S7 series) and intuitive Human-Machine Interface (HMI) touchscreens. This allows for easy adjustment of parameters such as embossing depth, speed, and pattern sequence, reducing operator error and enhancing productivity. Features include diagnostic capabilities, production tracking, and recipe management for various materials and patterns.

- Optimized Roller Gap Adjustment: Utilizes an automatic or semi-automatic roller gap adjustment system, often with motorized or hydraulic control, allowing for quick and accurate setup for different material thicknesses. This minimizes setup time and ensures uniform embossing pressure.

- Enhanced Safety Features: Designed with operator safety as a priority, incorporating emergency stop buttons, light curtains, overload protection, and comprehensive guarding as per international safety standards (e.g., CE, OSHA guidelines).

- Lower Maintenance Requirements: Through the use of high-quality components, self-lubricating bearings, and a modular design, our machines are engineered for minimal maintenance. Accessible lubrication points and diagnostic tools simplify routine upkeep.

- Energy Efficiency: Implementation of variable frequency drives (VFDs) for main motors and energy-saving hydraulic pump designs significantly reduces power consumption, contributing to lower operational costs and a reduced environmental footprint.

Vendor Comparison: Choosing the Right Metal Steel Plate Embossing Machine

Selecting a vendor for a Metal Steel Plate Embossing Machine involves evaluating critical factors beyond initial price. Performance, reliability, support, and customization capabilities are paramount for a long-term investment. This comparison table highlights key differentiators among leading manufacturers.

| Feature/Vendor | Our Machine (LW Roll Forming) | Competitor A (Premium) | Competitor B (Economy) |

|---|---|---|---|

| Embossing Precision | Excellent (±0.05mm depth) | Excellent (±0.04mm depth) | Good (±0.15mm depth) |

| Control System | Siemens/Rockwell PLC, intuitive HMI | Proprietary advanced PLC, custom HMI | Basic PLC, push-button interface |

| Roller Material/Hardness | Cr12MoV Tool Steel, HRC 58-62 | D2 Steel, HRC 60-64 | 45# Steel, HRC 48-52 |

| Energy Efficiency | High (VFD + Servo Hydraulics) | Very High (Full Servo Drives) | Standard (Fixed Speed Pump) |

| Customization Options | Extensive (Pattern, Width, Automation) | Limited to standard configurations | Very Limited |

| After-Sales Support | Global network, 24/7 online, onsite | Regional centers, dedicated tech support | Local distributors, limited remote |

| Certifications | CE, ISO 9001, SGS Verified | CE, ISO, TÜV Rheinland | Basic Quality Assurance |

Our offerings strike an optimal balance between advanced features, customization flexibility, and competitive pricing, making our Metal Steel Plate Embossing Machine an excellent long-term investment. We focus on delivering high-quality, durable equipment backed by comprehensive global support and a commitment to innovation.

Customized Solutions for Unique Requirements

Recognizing that every industrial application has unique demands, we specialize in providing highly customized solutions for our Metal Steel Plate Embossing Machine. Our engineering team collaborates closely with clients to develop configurations that precisely match their operational needs, material specifications, and production goals.

Areas of Customization:

- Pattern Design: From standard checkered plates to intricate decorative or brand-specific patterns, we can manufacture custom embossing rollers to create unique textures. This involves specialized CAD/CAM design and CNC engraving of rollers.

- Material Handling and Automation: Integration with automatic coil feeders, decoilers, flatteners, shearers, and stacking systems to create a fully automated production line. This includes synchronized speed control and robotic handling solutions.

- Machine Capacity and Size: Customization of machine width (up to 2500mm), thickness capacity (for heavier gauge plates), and production speed to align with specific output requirements.

- Control System Features: Tailoring the HMI for specific language requirements, integrating with existing factory MES/ERP systems, and adding advanced diagnostic or remote monitoring capabilities.

- Material Specific Enhancements: Modifications for processing exotic alloys, non-ferrous metals, or pre-painted sheets, including specialized roller materials or protective coatings to prevent surface damage.

- Environmental Adaptations: Design modifications for extreme operating conditions, such as high humidity, corrosive atmospheres, or explosive environments, adhering to relevant ATEX or NEMA standards.

Our expertise in engineering allows us to transform client visions into operational realities, delivering a Metal Steel Plate Embossing Machine that is not just a piece of equipment but a strategic asset optimized for their specific business model and market demands. We leverage over 20 years of manufacturing experience to ensure customized solutions maintain the highest standards of quality and performance.

Application Case Studies & Customer Testimonials

Our commitment to delivering high-performance embossing solutions is reflected in the successful projects we've completed and the positive feedback from our global clientele. These case studies exemplify the impact of our machinery in diverse industrial settings.

Case Study 1: Petrochemical Platform Safety Flooring

A major petrochemical company in the Middle East required durable, highly slip-resistant flooring for its offshore drilling platforms and onshore refinery walkways. Traditional grating proved insufficient in certain areas prone to oil and chemical spills. We provided a custom-engineered Metal Steel Plate Embossing Machine capable of embossing heavy-gauge (6mm) stainless steel plates with a specialized, aggressive diamond pattern. The solution significantly enhanced worker safety, reducing slips and falls by an estimated 45% based on internal incident reports. The corrosion-resistant design also ensured a minimal maintenance cycle in the harsh marine environment.

Case Study 2: Automotive Interior Panel Enhancement

A leading automotive interior supplier sought to introduce unique textured aluminum panels for luxury vehicle dashboards and door trims. They needed a machine capable of high-precision, fine-detail embossing on relatively thin (1.2mm) aluminum sheets, with minimal distortion. We supplied a compact, high-speed embossing machine with finely machined rollers and precise hydraulic control, allowing for intricate pattern replication. The client reported a 30% increase in production output for these panels and achieved a premium aesthetic that contributed to improved product differentiation in the competitive automotive market.

Customer Testimonial:

"We initially invested in a Metal Steel Plate Embossing Machine from LW Roll Forming for a new production line. Their team worked tirelessly to understand our specific needs for architectural cladding. The machine delivered not only on the promised precision for complex patterns but also exceeded our expectations in terms of operational efficiency and ease of maintenance. The support during installation and commissioning was exceptional. This machine has truly elevated our product offerings."

— Mr. Jian Li, Production Manager, Architectural Metal Solutions Inc.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust with our B2B partners is foundational. We provide comprehensive transparency regarding our products, processes, and after-sales commitments. This section addresses common inquiries and outlines our service guarantees.

Frequently Asked Questions (FAQ):

- Q: What types of metals can your Metal Steel Plate Embossing Machine process?

A: Our machines are designed to emboss a wide range of metals, including carbon steel, stainless steel (e.g., 304, 316), galvanized steel, aluminum, copper, and some specialized alloys. The specific capabilities depend on the machine configuration and roller design. - Q: How do I change the embossing pattern?

A: Changing patterns involves replacing the embossing rollers. Our machines feature a user-friendly roller change system, often with hydraulic assistance, allowing for efficient pattern swaps. Training is provided to ensure operators can perform this task safely and quickly. - Q: What is the typical service life of your embossing rollers?

A: With proper maintenance and depending on material type and usage frequency, our hardened and ground alloy steel rollers typically have a service life of 5-10 years before requiring regrinding or replacement. - Q: Can your machines be integrated into existing production lines?

A: Yes, our Metal Steel Plate Embossing Machines are designed for flexible integration. We offer solutions for synchronized operation with upstream (decoiling, leveling) and downstream (shearing, stacking) equipment. Our engineering team can assess your current setup and recommend optimal integration strategies.

Lead Time & Fulfillment Details:

Standard models of our Metal Steel Plate Embossing Machine typically have a lead time of 60-90 business days from order confirmation to shipment. For highly customized solutions, the lead time may extend to 90-150 business days, depending on the complexity of design and manufacturing. We maintain transparent communication throughout the production process, providing regular updates on milestones. Our logistics team ensures secure packaging and efficient global delivery, including assistance with customs documentation.

Warranty Commitments:

We provide a comprehensive 12-month warranty on all mechanical and electrical components of our Metal Steel Plate Embossing Machine from the date of installation or 18 months from the date of shipment, whichever comes first. This warranty covers manufacturing defects and component failures under normal operating conditions. Consumable parts and wear and tear are excluded. Extended warranty options are available upon request.

Customer Support Information:

Our dedicated customer support team is available 24/7 to address any technical inquiries or operational challenges. We offer:

- Online & Phone Support: Immediate assistance via phone, email, or live chat for troubleshooting and guidance.

- Remote Diagnostics: Capabilities for remote access to PLC systems for diagnostics and software updates, minimizing downtime.

- Onsite Technical Support: Deployment of experienced engineers for installation, commissioning, preventative maintenance, and repair services globally.

- Spare Parts Availability: A robust inventory of genuine spare parts ensures quick replacement and minimal disruption to your production.

- Training Programs: Comprehensive training for your operators and maintenance staff on machine operation, safety protocols, and routine maintenance.

Authoritative References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM A6/A6M - 19a, Standard Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling. ASTM International.

- "Advanced Manufacturing Processes: Material Forming, Welding, and Machining" by J. T. Black and Ronald A. Kohser. Wiley.

- European Committee for Standardization, Machinery Directive 2006/42/EC.

- "Metal Forming: Fundamentals and Applications" by Taylan Altan and George Ngaile. ASM International.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025