Precision 988 Corrugated Roofing Sheet Forming Machine - Durable & Efficient

Unlocking Global Opportunities: The 135th Canton Fair and the Future of Roll Forming Technology

Exploring the cutting edge of industrial machinery, automation, and precision manufacturing.

The 135th Canton Fair: A Global Nexus for Industrial Machinery & Advanced Manufacturing

The Canton Fair, officially known as the China Import and Export Fair, stands as an unparalleled global beacon for international trade and industrial sourcing. With its 135th iteration, this monumental event continues its legacy as a critical platform where innovative technologies meet burgeoning market demands, facilitating billions in trade volume annually. For B2B decision-makers in sectors ranging from construction to automotive, it's more than just an exhibition; it's an indispensable hub for discovering cutting-edge industrial equipment, forging strategic partnerships, and staying ahead of global manufacturing trends.

This year, the spotlight shines brightly on advancements in heavy machinery, particularly within the roll forming industry. From specialized presses to sophisticated profiling lines, the fair offers an exclusive glimpse into the future of metal processing. For businesses seeking high-efficiency solutions like the 988 Corrugated roofing sheet forming machine, the Canton Fair provides an invaluable opportunity to engage directly with top manufacturers, evaluate the latest innovations, and secure competitive advantages in an increasingly globalized marketplace.

Industry Trend Spotlight: Revolutionizing Roll Forming Technology

The industrial manufacturing landscape is in a constant state of evolution, driven by relentless innovation and market demands. The roll forming sector, crucial for infrastructure and construction, is no exception. At the 135th Canton Fair, several key trends emerged as pivotal, shaping the next generation of machinery, including advanced corrugated roofing sheet forming machines.

Automation & Digital Control: The Smart Factory Revolution

The shift towards smarter, more autonomous production environments is undeniable. Modern roll forming machines, including robust solutions like the 988 Corrugated roofing sheet forming machine, are increasingly equipped with advanced PLC (Programmable Logic Controller) systems and intuitive HMI (Human-Machine Interface) touchscreens. These features enable precise control over production parameters, minimize human error, and streamline operational workflows. Furthermore, the integration of IoT (Internet of Things) capabilities is gaining significant traction, allowing for remote monitoring, predictive maintenance, and real-time diagnostics, thereby enhancing uptime and operational efficiency.

High-Speed & Precision: Maximizing Throughput and Quality

In a competitive market, faster production cycles without compromising quality are paramount. Manufacturers are focusing on developing roll forming machines capable of higher operating speeds while maintaining tighter tolerances for complex profiles. This dual emphasis on speed and precision ensures that end products, such as corrugated roofing sheets, meet stringent quality standards and can be produced at volumes that satisfy aggressive project timelines. Advanced servo-driven systems and sophisticated sensor technology are key enablers of this trend.

Material Versatility: Adapting to Diverse Industry Needs

The demand for machines that can handle a broader spectrum of materials and thicknesses is rising. Modern roll forming equipment must efficiently process high-strength steel, various grades of aluminum, pre-painted metals, and even specialized alloys, often with varying gauges. This versatility allows manufacturers to cater to diverse industry applications, from lightweight construction panels to heavy-duty structural components, all from a single, adaptable machine platform.

Energy Efficiency: Sustainable Manufacturing at Its Core

With growing global awareness of environmental impact and rising energy costs, energy efficiency has become a critical design criterion. New generations of roll forming machines feature more efficient motors, optimized hydraulic systems, and intelligent power management units that reduce energy consumption without sacrificing performance. This not only lowers operational costs for businesses but also contributes to more sustainable manufacturing practices.

Customization & Modularity: Flexibility for Dynamic Markets

Market demands are rarely static. Manufacturers are increasingly seeking roll forming machines that offer flexible designs, allowing for quick adaptation to new product profiles or evolving production needs. Modularity in design facilitates easier upgrades, maintenance, and the ability to produce a diverse range of products, enhancing a company's agility and responsiveness to changing market trends.

Market Data & Future Outlook: Steady Growth Ahead

The industrial manufacturing and machinery market is projected for steady and robust growth globally. This expansion is primarily driven by significant infrastructure development projects, rapid urbanization, particularly in emerging economies, and the pervasive global push towards automation and digitalization across all industries. Key growth drivers include sustained demand from the construction, automotive, and logistics sectors. While geopolitical uncertainties, raw material price volatility, and the perennial challenge of securing skilled labor pose hurdles, the market will witness continued substantial investment in smart factories, AI-driven solutions, and sustainable manufacturing practices. The overarching emphasis will remain on maximizing efficiency, enhancing resilience, and fostering innovation.

Emerging focus areas for the industry include:

- Smart Manufacturing: Integration of advanced analytics, machine learning, and AI for optimized production.

- Automation Integration: Seamless connectivity between different stages of the production line.

- Green Technologies: Development of eco-friendly processes and energy-saving machinery.

- Global Supply Chain Resilience: Building robust, adaptable supply networks to mitigate disruptions.

- Precision Engineering: Achieving ever-higher levels of accuracy and repeatability in manufacturing.

Profiles of Leading Roll Forming Machine Manufacturers at Canton Fair

The 135th Canton Fair proudly hosted some of the world's most innovative and reliable manufacturers of roll forming machinery. These companies are at the forefront of engineering excellence, delivering solutions that empower industries globally. Here, we highlight a key player and several other prominent names that stood out.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD: A Benchmark in Roll Forming

Standing out among the top exhibitors, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD solidified its position as a go-to partner for advanced roll forming solutions. Specializing in a comprehensive range of machines, from those producing versatile corrugated roofing sheets to complex purlin and decking profiles, LONGWAY brings a blend of technical prowess and international business acumen to the global stage.

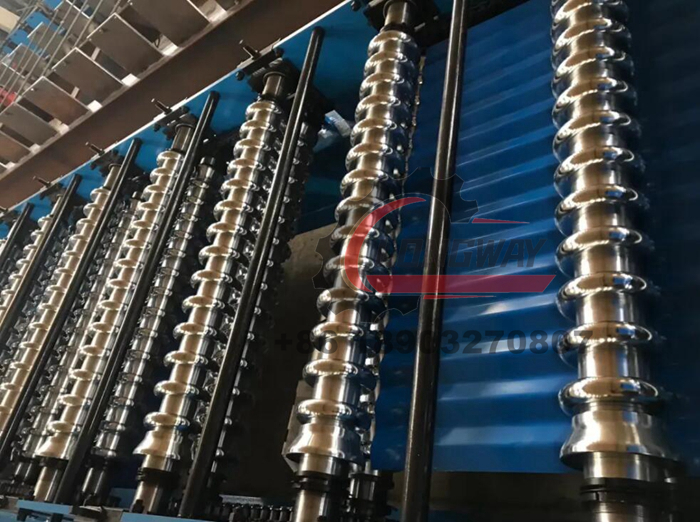

Their flagship product, the 988 Corrugated roofing sheet forming machine, is a prime example of their engineering excellence. Designed for high-speed precision and robust performance, this machine is critical for construction projects requiring durable and aesthetically pleasing roofing solutions. It embodies the latest trends in automation, featuring intuitive controls and a sturdy design built for continuous operation.

Key attributes that define CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD's competitive edge:

- Specialized Expertise: Their strong focus on various types of roll-forming machines, particularly the 988 Corrugated roofing sheet forming machine, showcases deep product knowledge and a high capability in precision engineering.

- International Trade Focus: The inclusion of "International Trade" in their company name underscores a robust infrastructure and extensive experience dedicated to global exports and comprehensive client support worldwide.

- Competitive Pricing: As a leading Chinese manufacturer, LONGWAY is adept at offering highly cost-effective solutions without compromising on the quality and reliability essential for industrial machinery.

- Customization Capability: Recognizing the diverse applications of roll-forming, they excel at tailoring machines to meet specific customer requirements and unique production needs, ensuring optimal performance for varied projects.

- After-Sales Support: Critical for fostering international trust, LONGWAY emphasizes exceptional after-sales service and technical support, providing peace of mind and operational continuity for their global clientele.

Learn more about the 988 Corrugated roofing sheet forming machine at lwrollformingmachine.com

Other Noteworthy Global Roll Forming Machine Manufacturers:

- Samco Machinery (Canada): Renowned for engineered solutions and robust equipment for diverse industries, with a strong focus on precision and durability.

- Hayes International (New Zealand): A leader in advanced roll forming technology, particularly for roofing and cladding profiles, known for innovation and reliability.

- The Bradbury Group (USA): A global industrial machinery powerhouse, offering a wide array of metal processing equipment, celebrated for its integrated solutions and heavy-duty designs.

- Hebei Botou Golden Integrity Roll Forming Machine Co., Ltd. (China): A significant Chinese player known for its comprehensive range of roll forming machines and strong commitment to technological upgrades.

- Sinoform Machinery Co., Ltd. (China): Offers a broad portfolio of cost-effective and efficient roll forming machines, catering to various international market demands.

Market Outlook & Opportunities in Roll Forming

The horizon for the roll forming industry is bright, marked by transformative trends and significant growth opportunities. Buyer demand is increasingly sophisticated, pushing manufacturers to innovate beyond conventional designs. Upcoming trends indicate a strong lean towards integrated solutions that offer not just machines, but complete production lines with minimal human intervention.

Opportunities abound, particularly in three critical areas:

- Automation & Industry 4.0 Integration: The demand for fully automated roll forming lines, capable of real-time data analysis, predictive maintenance, and seamless integration into larger factory ecosystems, is surging. This includes advanced systems like those found in the 988 Corrugated roofing sheet forming machine, which can be part of a smart factory setup.

- Smart Manufacturing: The adoption of AI and machine learning to optimize material usage, reduce waste, and enhance product consistency is a major focus. Buyers are looking for machines that can "learn" and adapt.

- Sustainability & Green Technologies: Energy-efficient machines, processes that minimize scrap, and the ability to work with recycled or environmentally friendly materials are becoming non-negotiable for many global buyers.

Emerging markets in Southeast Asia, Africa, and Latin America, driven by rapid urbanization and infrastructure development, present immense opportunities for the deployment of advanced roll forming technologies, including the production of essential building materials like corrugated roofing sheets.

Buyer/Business Takeaways: Strategic Investments in Roll Forming

For B2B decision-makers, investing in high-quality roll forming machinery is not merely a purchase; it's a strategic move towards enhanced productivity, reduced operational costs, and sustainable growth. Here’s why and how to approach it:

Why Invest in Advanced Roll Forming Machines (e.g., Corrugated Roofing Sheet Forming Machines)?

- Increased Efficiency & Output: Modern machines, like the 988 Corrugated roofing sheet forming machine, offer higher speeds and greater automation, significantly boosting production capacity.

- Superior Product Quality: Precision engineering ensures consistent, high-quality output, reducing defects and waste.

- Cost Reduction: Automation, energy efficiency, and material versatility lead to lower labor, energy, and raw material costs over the long term.

- Market Adaptability: Customizable and modular designs allow for quick adjustments to produce various profiles, keeping your business agile.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Thorough Due Diligence: Research potential partners extensively. Look for established companies with a strong export history, like CANGZHOU LONGWAY, which emphasizes international trade.

- Clarify Specifications: Be extremely precise with your technical requirements, material specifications, and desired output. Provide drawings and samples if possible.

- Understand After-Sales Support: Confirm the availability of spare parts, technical assistance, and warranty terms. A strong after-sales commitment, as offered by LONGWAY, is crucial.

- Visit & Verify: If feasible, visit the factory or engage third-party inspection services to verify manufacturing quality and capabilities. Virtual tours and detailed video demonstrations can also be helpful.

- Negotiate Clearly: Discuss payment terms, delivery schedules, and any customization needs transparently to avoid misunderstandings.

Future-Proof Strategies:

To future-proof your investment, consider machines that are:

- Scalable: Can be integrated into larger automated systems or upgraded in the future.

- Data-Enabled: Equipped with sensors and connectivity for data collection and analysis to optimize performance.

- Energy-Efficient: Align with global sustainability goals and reduce long-term operational costs.

- Versatile: Capable of handling a range of materials and profiles to meet evolving market demands, such as different types of corrugated roofing sheets.

Conclusion: The Canton Fair's Enduring Impact on Roll Forming

The 135th Canton Fair once again affirmed its critical role in shaping the global industrial machinery market, particularly for specialized equipment like advanced roll forming machines. It served as a powerful testament to the industry's rapid evolution, showcasing a clear trajectory towards greater automation, precision, and sustainability. For B2B decision-makers, the insights gained and connections made at such an event are instrumental in driving future growth and maintaining a competitive edge.

Companies like CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD continue to lead the charge, offering innovative and reliable solutions such as the advanced 988 Corrugated roofing sheet forming machine. Their commitment to quality, customization, and comprehensive international support makes them a valuable partner in the dynamic world of manufacturing.

Ready to elevate your production capabilities?

Explore the full potential of high-quality roll forming technology.

Discover the 988 Corrugated Roofing Sheet Forming MachineVisit CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD's product page today.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025