Euro 1100 Metal Roof Tile Making Machine - High Quality & Efficient

Industry Trends in Metal Roof Tile Manufacturing

The global construction industry is experiencing a robust shift towards sustainable and durable building materials, with metal roofing at the forefront. Driven by increasing demand for resilient, energy-efficient, and aesthetically versatile roofing solutions, the market for metal roof tiles is expanding significantly. Key trends include the adoption of advanced automation in manufacturing, a focus on high-strength yet lightweight materials like PPGI (pre-painted galvanized iron) and aluminum, and the integration of smart controls for optimized production efficiency. Furthermore, there's a growing emphasis on precision engineering to produce interlocking designs that enhance weather resistance and ease of installation. Manufacturers are also exploring innovative coatings that offer superior corrosion resistance and thermal reflectivity, contributing to reduced energy consumption in buildings. The demand for customizable profiles to meet diverse architectural requirements across commercial, industrial, and residential sectors further fuels the need for flexible and efficient roll forming solutions.

In this dynamic landscape, the efficiency, reliability, and precision of manufacturing equipment are paramount. Companies are investing in next-generation roll forming machines that can handle a wider range of material specifications and produce complex profiles with minimal waste and maximum uptime. This paradigm shift underscores the importance of machinery like the Euro 1100 Metal roof tile making machine, which is engineered to meet these evolving industry demands by combining robust construction with advanced automation capabilities, ensuring high-quality output and operational longevity.

Fig 1: Advanced control panel of a modern metal roof tile machine.

Moreover, the industry is seeing stricter quality control and testing standards, such as ISO 9001 for quality management and specific material testing standards like ASTM for steel properties. These regulations necessitate manufacturing equipment capable of consistent, high-tolerance production. The integration of IoT and AI for predictive maintenance and real-time monitoring is also gaining traction, paving the way for more intelligent and autonomous production lines.

Detailed Process Flow of the Euro 1100 Metal roof tile making machine

The manufacturing process of metal roof tiles using the Euro 1100 Metal roof tile making machine is a highly automated and precise sequence designed to transform raw metal coils into finished roofing panels. This sophisticated roll forming line integrates several critical stages, each optimized for efficiency and quality output. The typical materials processed include PPGI (pre-painted galvanized iron), galvanized steel, Galvalume steel, and aluminum sheets, with thicknesses commonly ranging from 0.3mm to 0.8mm and coil widths up to 1250mm.

Process Steps:

- Decoiling (Uncoiling): The process begins with the raw material coil, often weighing several tons, being loaded onto a hydraulic or manual uncoiler. This unit steadily feeds the metal strip into the machine, ensuring smooth, tension-controlled unwinding without deforming the material. The uncoiler's capacity is typically engineered to minimize material changeovers, enhancing continuous production.

- Feeding and Guiding: The uncoiled metal strip is then directed through a precision feeding and guiding mechanism. This system ensures the strip remains perfectly aligned throughout the subsequent forming stages, preventing material wander and maintaining dimensional accuracy of the finished product. Proper guiding is crucial for consistent tile profiles.

- Roll Forming: This is the core of the machine's operation. The metal strip passes through a series of precisely engineered roller stations. Each station progressively shapes the material, incrementally bending it into the desired roof tile profile. The rollers, often made from high-grade steel (e.g., GCr15 or 45# steel) and hard chrome plated, are designed via advanced CAD/CAM software to minimize stress on the material, ensuring structural integrity and a flawless surface finish. The number of forming stations can vary (e.g., 18-22 groups) depending on the complexity of the tile profile.

- Hydraulic Cutting: Once the desired profile is fully formed along the entire length of the production run, a hydraulic cutting device precisely cuts the continuous tile strip into predetermined lengths. The cutting blade, often made of Cr12Mov or SKD11 steel, ensures clean, burr-free cuts. This stage is synchronized with the roll forming speed via a PLC control system for optimal length accuracy.

- Hydraulic Pressing/Embossing (Optional): For certain tile designs, particularly those mimicking traditional clay tiles or requiring enhanced structural rigidity, a hydraulic pressing or embossing unit may be integrated post-cutting. This system applies a specific pattern or strengthens certain areas of the tile, adding to its aesthetic appeal and functional performance.

- Output and Stacking: The finished metal roof tiles are then conveyed out of the machine and typically stacked automatically or manually for packaging and storage. This final stage is designed to handle the tiles carefully to avoid any surface damage.

Manufacturing Processes and Standards:

The components of the Euro 1100 Metal roof tile making machine undergo rigorous manufacturing processes to ensure durability and precision. Rollers are typically CNC machined from high-quality alloy steel, followed by heat treatment and hard chrome plating to achieve exceptional hardness (HRC 58-62) and wear resistance. Machine frames are fabricated from robust structural steel (e.g., H-beam or channel steel), welded, and stress-relieved to prevent deformation over long-term operation. Key electrical and hydraulic components are sourced from reputable international brands (e.g., Siemens, Mitsubishi, Schneider, Bosch Rexroth) to guarantee reliability and ease of maintenance.

Testing standards adhere to international benchmarks such as ISO 9001 for quality management systems, ensuring every machine component and the final assembled unit meets stringent performance criteria. Material conformity is often checked against ASTM or EN standards. The machine’s operational life is designed for upwards of 15-20 years with proper maintenance, reflecting its robust engineering. Target industries include petrochemical, metallurgy, infrastructure, and specialized building construction sectors where durable and high-performance roofing solutions are critical.

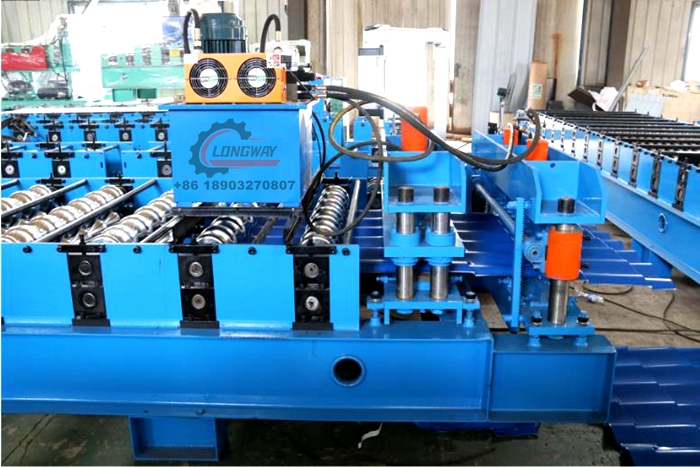

Fig 2: Roll forming stations meticulously shaping the metal strip.

Advantages in Application Scenarios:

- Energy Saving: By producing high-quality metal tiles often used with cool-roof coatings, the machine contributes to energy-efficient buildings. The precise profiling also ensures minimal material waste during production.

- Corrosion Resistance: The machine processes pre-coated and galvanized materials, ensuring the final product possesses excellent corrosion resistance, vital for longevity in harsh environments like coastal regions or industrial zones.

- High Production Capacity: With forming speeds typically ranging from 8-12 meters per minute, the machine ensures high output volumes, reducing lead times for large-scale projects.

- Dimensional Accuracy: The precise roll forming and cutting systems guarantee tiles with consistent dimensions, facilitating quick and error-free installation on site.

Technical Specifications of the Euro 1100 Metal roof tile making machine

The Euro 1100 Metal roof tile making machine is engineered with robust technical specifications to deliver high performance and reliable operation. Below is a detailed table outlining its key parameters:

Product Specification Table:

| Parameter | Specification | Unit/Details |

|---|---|---|

| Applicable Material | PPGI, Galvanized Steel, Galvalume, Aluminum | Yield Strength: 235-345 MPa |

| Material Thickness | 0.3 - 0.8 | mm |

| Feeding Coil Width | Max 1250 | mm |

| Forming Speed | 8 - 12 (adjustable) | m/min |

| Number of Forming Stations | Approx. 18-22 | Groups, depending on profile |

| Roller Material | High Grade 45# Steel with Hard Chrome Plating | Hardness HRC 58-62 |

| Main Motor Power | 7.5 | kW |

| Hydraulic Station Power | 3.0 | kW |

| Control System | PLC Automatic Control (Siemens/Mitsubishi optional) | Touch Screen Interface |

| Cutting Type | Hydraulic Post-Cutting | Cr12Mov or SKD11 blade |

| Machine Structure | Welded Steel Frame (H-beam or Channel Steel) | Stress-relieved |

| Total Weight | Approx. 9-12 | Tons |

| Machine Dimensions (L x W x H) | Approx. 8000 x 1500 x 1500 | mm (excluding uncoiler/output tables) |

| Power Supply | 380V/50Hz/3Phase (customizable) | V/Hz/Phase |

| Certifications | CE, ISO 9001 |

These specifications highlight the robust design and advanced capabilities of the machine, ensuring it meets the demanding requirements of modern metal roof tile production. The integrated PLC system allows for precise control over length, speed, and batch production, minimizing human error and maximizing operational efficiency.

Application Scenarios

The versatility and high-performance output of the Euro 1100 Metal roof tile making machine make it suitable for a wide array of application scenarios across various industries and construction types. Its ability to produce durable, weather-resistant, and aesthetically pleasing metal roof tiles positions it as a critical asset for manufacturers catering to diverse market demands.

Key Application Areas:

- Industrial and Commercial Buildings: Large-span structures such as factories, warehouses, logistics centers, shopping malls, and exhibition halls frequently utilize metal roofing due to its lightweight nature, ease of installation, and long service life. The machine supports high-volume production required for such extensive projects.

- Agricultural Structures: Barns, livestock shelters, greenhouses, and storage facilities benefit from the robustness and low maintenance of metal roofs. The corrosion resistance of the tiles produced by this machine is particularly advantageous in agricultural environments exposed to various chemicals and elements.

- Residential Construction: Increasingly, modern residential homes and multi-unit dwellings are opting for metal roof tiles. Their aesthetic flexibility (mimicking traditional tiles, slate, or shakes), energy efficiency (cool roof options), and superior durability against extreme weather conditions make them a popular choice. The machine can produce profiles suitable for various architectural styles.

- Public and Institutional Buildings: Schools, hospitals, administrative buildings, and community centers require roofing that combines safety, longevity, and often, specific aesthetic considerations. Metal tiles offer excellent fire resistance and can be customized to blend with local architectural themes.

- Infrastructure Projects: Bus terminals, train stations, airport hangars, and other transport-related structures demand highly durable and low-maintenance roofing solutions capable of withstanding heavy environmental loads and high traffic.

- Renewable Energy Installations: The compatibility of metal roofs with solar panel installations (both mounted and integrated) makes them a preferred choice for green buildings. The structural integrity of tiles produced by the machine ensures a stable base for such systems.

The ability of the Euro 1100 Metal roof tile making machine to handle various materials and produce consistent, high-quality tiles ensures that manufacturers can cater to these diverse markets effectively, providing solutions that prioritize structural integrity, aesthetic appeal, and long-term cost-effectiveness.

Technical Advantages and Performance Edge

The design and engineering of the Euro 1100 Metal roof tile making machine provide a significant technical advantage in the highly competitive metal roofing market. These advantages translate directly into lower operational costs, higher product quality, and enhanced production efficiency for manufacturers.

Fig 3: Precision-engineered rollers for optimal profile accuracy.

Key Advantages:

- Precision Roll Forming Technology: The machine employs multi-stage progressive roll forming, meticulously designed using finite element analysis (FEA) to ensure that each bending stress is evenly distributed. This reduces material stress and spring-back, resulting in consistently accurate profiles that meet tight dimensional tolerances (e.g., ±0.5mm for length, ±0.3mm for width). The precision of the rollers, often CNC ground and polished, is critical for achieving the intricate interlocking designs essential for superior weatherproofing.

- Advanced PLC Control System: Equipped with a Siemens or Mitsubishi PLC, the system offers intuitive operation via a touchscreen HMI. It provides real-time monitoring of production parameters, fault diagnostics, and allows for quick adjustments of length, batch quantity, and speed. This intelligence minimizes downtime and optimizes material utilization, often achieving material savings of 2-5% compared to less precise systems.

- Robust and Durable Construction: The main frame is constructed from heavy-duty structural steel, welded with precision, and stress-relieved to prevent long-term deformation. This robust build ensures stability during high-speed operation and extends the machine's service life beyond 15 years, even under continuous heavy-duty use. The use of high-quality bearings and transmission components further enhances reliability.

- High-Efficiency Hydraulic System: The integrated hydraulic cutting and optional pressing systems feature high-performance pumps and valves (e.g., Bosch Rexroth or Yuken equivalents) that deliver fast, precise, and powerful operations. This ensures clean cuts and efficient pressing cycles, contributing to higher overall production rates. The system is designed for energy efficiency, reducing power consumption during idle periods.

- Versatility in Material Handling: The machine can seamlessly process various metal types and thicknesses, from pre-painted galvanized iron (PPGI) to aluminum, without extensive retooling. This flexibility allows manufacturers to cater to a broader market segment and respond quickly to changing material trends.

- Optimized Tooling Design: The roll forming dies are designed for quick changeover and minimal maintenance. The material for the rollers (e.g., 45# steel or GCr15) is selected for optimal wear resistance and hardness, ensuring prolonged tool life and consistent product quality, even with abrasive materials.

These technical advantages underscore the Euro 1100 Metal roof tile making machine's position as a leading solution for metal roof tile production, offering an unparalleled blend of precision, durability, and operational intelligence crucial for competitive manufacturing.

Vendor Comparison: Euro 1100 Metal roof tile making machine vs. Competitors

When investing in high-value manufacturing equipment like a metal roof tile making machine, a comprehensive vendor comparison is essential. This section benchmarks the Euro 1100 Metal roof tile making machine against typical offerings from major competitors in terms of key performance indicators, features, and overall value proposition.

Product Comparison Table:

| Feature/Parameter | Euro 1100 (Our Product) | Competitor A (High Speed Focus) | Competitor B (Modular Design Focus) |

|---|---|---|---|

| Max Forming Speed | 8-12 m/min | 10-15 m/min | 7-10 m/min |

| Profile Precision | Excellent (±0.5mm length, ±0.3mm width) | Good (±0.8mm length, ±0.5mm width) | Very Good (±0.4mm length, ±0.2mm width) |

| PLC System | Siemens/Mitsubishi (Advanced HMI) | Basic PLC (Limited HMI) | Advanced PLC (Custom Software) |

| Roller Material/Treatment | 45# Steel, Hard Chrome Plated (HRC 58-62) | 45# Steel, Quenched (HRC 52-55) | GCr15, Hard Chrome Plated (HRC 60-63) |

| Hydraulic Components | International Brand (e.g., Bosch Rexroth equivalents) | Local/Standard OEM | Premium European Brand |

| Ease of Operation/Maintenance | High (User-friendly HMI, accessible components) | Medium (Requires more manual adjustment) | High (Modular design, quick swap parts) |

| Customization Options | Extensive (Profile, speed, material handling) | Limited to basic profile changes | Very High (Flexible modules) |

| Price Point | Mid-to-High Range | Low-to-Mid Range | High Range |

| Typical Lead Time | 60-90 days | 45-75 days | 90-120 days |

This comparison highlights that while some competitors might offer slightly higher speeds (often at the expense of precision or component quality) or highly modular, but more expensive, systems, the Euro 1100 Metal roof tile making machine strikes an optimal balance. It delivers excellent precision, robust construction, advanced control, and significant customization capabilities at a competitive price point, offering superior long-term value and ROI for diverse manufacturing needs. Its blend of modern technology and proven reliability positions it as a leading choice for discerning buyers.

Customized Solutions and Tailored Engineering

Recognizing that every client's production requirements are unique, we offer extensive customized solutions for the Euro 1100 Metal roof tile making machine. Our engineering team works closely with clients to understand their specific profile designs, material preferences, production volumes, and factory layouts, ensuring the delivered machine is perfectly aligned with their operational goals.

Areas of Customization:

- Profile Design: We can develop and integrate tooling for virtually any metal roof tile profile, from classic Roman tiles and Spanish tiles to modern standing seam designs or complex interlocking systems. Our CAD/CAM capabilities ensure precise replication of customer designs or assist in new profile development.

- Material Handling Systems: Customization extends to the uncoiler capacity (e.g., heavier coils up to 15 tons), integration of film laminators for delicate finishes, or specialized tensioning systems for very thin materials.

- Speed and Production Capacity: While the standard machine offers excellent speed, we can optimize motor power and roller configurations for higher speeds or specific throughput targets, catering to high-volume operations.

- Control System Integration: Beyond standard PLC options, we can integrate advanced features like remote diagnostics, data logging for Industry 4.0 readiness, or specific HMI functionalities tailored to operator preferences.

- Auxiliary Equipment: This includes custom-designed output tables, automatic stackers, punching units for fastening holes, or embossing units for specific textures or logos.

- Safety Features: While our machines meet CE standards, additional safety guards, light curtains, or emergency stop integrations can be implemented to comply with specific regional safety regulations or client preferences.

Our commitment to tailored engineering ensures that each Euro 1100 Metal roof tile making machine delivered is not just a piece of equipment but a precisely engineered solution that seamlessly integrates into the client's existing workflow and contributes directly to their competitive advantage. This consultative approach, backed by years of industry experience and a dedicated R&D team, is a cornerstone of our service offering.

Application Case Studies

The proven capabilities of the Euro 1100 Metal roof tile making machine are best demonstrated through real-world application success. Below are illustrative case studies showcasing its impact across different projects and client needs.

Case Study 1: Large-Scale Industrial Complex Roofing

A major industrial developer in Southeast Asia required a high-volume production solution for roofing a new series of logistics warehouses covering over 500,000 square meters. They needed a machine capable of producing a specific 'Trapezoidal' profile with extreme consistency in length (up to 12 meters) and width, using 0.5mm Galvalume steel.

- Solution Provided: We supplied a customized Euro 1100 Metal roof tile making machine equipped with an enhanced uncoiler for 10-ton coils, a 20-station roll forming section optimized for the Trapezoidal profile, and an advanced PLC with integrated length sensors for precision cutting.

- Results: The client achieved an average production rate of 10 m/min, meeting their aggressive construction schedule. The high precision ensured minimal waste and seamless on-site installation, reducing labor costs by 15% and project completion time by 10% compared to their previous projects. The long-term durability of the tiles, facilitated by consistent machine output, was also a key factor in project success.

Case Study 2: Architectural Residential Roofing Specialist

A boutique roofing manufacturer specializing in high-end residential projects in Europe sought a machine capable of producing complex 'Spanish Tile' profiles from 0.45mm pre-painted aluminum, requiring exceptional aesthetic fidelity and minimal surface blemishes. Quality and finish were paramount.

- Solution Provided: A custom Euro 1100 Metal roof tile making machine was configured with specially polished rollers (GCr15, hard chrome plated to HRC 62), a gentle guiding system, and a post-forming hydraulic embossing unit to create the distinctive Spanish tile wave and texture. The PLC was programmed for precise speed control to prevent material stretching and ensure a flawless painted surface.

- Results: The client reported a significant improvement in product quality and surface finish, with rejection rates dropping by 8%. The machine's ability to handle delicate aluminum with high precision allowed them to expand their product offerings and secure more high-value residential contracts, strengthening their market position as a premium supplier.

Fig 4: Completed metal roof tiles showcasing precise profiling.

Case Study 3: Government Infrastructure Project (Water Supply & Drainage)

A contractor involved in public infrastructure development needed a robust solution for roofing water treatment facilities and pumping stations. These buildings required corrugated metal sheets known for their strength and extreme corrosion resistance, often used in environments with high humidity and chemical exposure.

- Solution Provided: We configured a Euro 1100 Metal roof tile making machine for heavy-gauge corrugated profiles (0.8mm galvanized steel). The machine was outfitted with heavy-duty structural components and a specialized cutting system to handle the thicker material efficiently and durably. The control system was calibrated for high repeatability to ensure all roof sections matched perfectly.

- Results: The client successfully produced over 200,000 meters of corrugated roofing for multiple sites within a tight schedule. The machine’s reliability under continuous operation and its ability to consistently produce tiles that met strict government specifications for durability and longevity proved invaluable, leading to further contracts for the client.

Frequently Asked Questions (FAQ)

- Q1: What materials can the Euro 1100 Metal roof tile making machine process?

- A1: The machine is designed to efficiently process a range of materials including Pre-Painted Galvanized Iron (PPGI), Galvanized Steel, Galvalume Steel, and Aluminum, with thicknesses typically from 0.3mm to 0.8mm.

- Q2: What is the maximum production speed?

- A2: The standard forming speed is between 8 to 12 meters per minute, depending on the material thickness and profile complexity. This can be optimized for specific requirements.

- Q3: How long does installation and commissioning take?

- A3: Typically, installation and commissioning by our engineers take approximately 7-10 working days, including operator training. This period can vary based on the complexity of any customized features.

- Q4: Are spare parts readily available?

- A4: Yes, we maintain a comprehensive inventory of critical spare parts. For international orders, a recommended spare parts list is provided, and we ensure prompt global shipping to minimize any potential downtime.

- Q5: Can the machine produce multiple profiles?

- A5: While the standard machine is optimized for one primary profile, we offer multi-profile solutions, either through quick-change tooling systems or by supplying additional roll forming heads, as part of our customized solutions.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment:

Standard lead time for a Euro 1100 Metal roof tile making machine typically ranges from 60 to 90 working days from the receipt of the down payment and final technical confirmation. This duration allows for precision manufacturing, rigorous testing, and quality control. For highly customized machines, lead times may extend up to 120 working days. We provide regular updates on manufacturing progress and coordinate logistics closely with clients for efficient global delivery.

Warranty Commitments:

We stand behind the quality and reliability of the Euro 1100 Metal roof tile making machine with a comprehensive warranty package. The main machine body and mechanical components are covered by a 24-month warranty from the date of commissioning or 26 months from the date of shipment, whichever comes first. Electrical components and hydraulic parts are covered for 12 months. This warranty covers manufacturing defects and ensures free replacement of parts under normal operating conditions. Wear and tear parts are excluded.

Customer Support & After-Sales Service:

- Technical Support: Our dedicated technical support team is available 24/7 via phone, email, and online conferencing to address operational queries, troubleshooting, and provide remote assistance.

- On-site Installation & Training: Experienced engineers are dispatched globally for machine installation, commissioning, and comprehensive training for your operational and maintenance personnel, ensuring your team is fully proficient.

- Spare Parts Management: We maintain a robust supply chain for original spare parts, guaranteeing availability and rapid delivery to minimize any potential operational interruptions. A detailed spare parts manual is provided with each machine.

- Preventive Maintenance Programs: We offer tailored preventive maintenance schedules and service contracts to help extend the life of your machine and ensure continuous peak performance.

Our commitment extends beyond the sale, aiming to build long-term partnerships through exceptional support and service.

References

- International Organization for Standardization (ISO). (2015). ISO 9001: Quality management systems – Requirements.

- American Society for Testing and Materials (ASTM) International. (Various Standards). Standards for Steel, Stainless Steel and Related Alloys.

- European Committee for Standardization (CEN). (Various Standards). EN Standards for Construction Products and Metals.

- Metal Construction Association (MCA). (2023). Metal Roofing Design Guide.

- The Fabricator. (2022). Advanced Roll Forming Techniques for High-Strength Steels. FMA Communications.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025