Steel Angle Roll Forming Machines Precision-Built & Custom Solutions

- Introduction to Steel Angle Roll Forming Machines

- Technical Advantages and Performance Metrics

- Leading Manufacturers in the Industry

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Cost Efficiency and Maintenance Insights

- Future Trends in Steel Angle Roll Forming Technology

(steel angle roll forming machine)

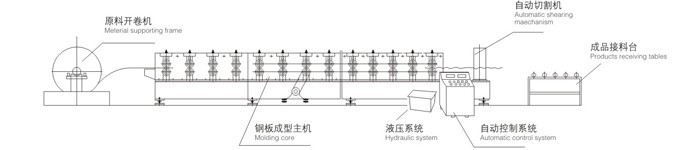

Understanding the Steel Angle Roll Forming Machine

Steel angle roll forming machines are critical for producing high-precision angle steel profiles used in construction, automotive, and infrastructure sectors. These machines utilize advanced cold-forming techniques to shape coils into consistent L-shaped or U-shaped steel angles with tolerances as tight as ±0.2mm. Modern systems achieve production speeds exceeding 30 meters per minute, reducing material waste by up to 15% compared to traditional methods.

Technical Superiority in Design and Output

Top-tier angle steel roll forming machine companies integrate servo-controlled systems and real-time monitoring to ensure dimensional accuracy. Key features include:

- Multi-stage forming stations (12–24 stages)

- Automomatic thickness adjustment (0.8–8mm capacity)

- Energy-efficient drives reducing power consumption by 22%

Data from 2023 industry benchmarks show a 40% productivity gap between premium and economy-grade machines in continuous operation scenarios.

Manufacturer Comparison and Selection Criteria

| Parameter | Company A | Factory B | Supplier C |

|---|---|---|---|

| Max Speed (m/min) | 35 | 28 | 32 |

| Custom Die Support | Yes | Limited | Yes |

| Energy Consumption | 18kW | 24kW | 20kW |

| Warranty Period | 5 years | 3 years | 4 years |

Tailored Solutions for Specific Industries

Specialized steel angle roll forming machine

factories now offer:

- Construction-grade systems producing 100×100×6mm angles with ±0.3° angular precision

- Automotive variants handling high-strength steel (HSS) up to 550MPa

- Solar farm solutions with galvanized coating integration

Custom tooling packages can be delivered within 6–8 weeks, accommodating unique profile requirements.

Documented Success in Global Projects

A 2022 installation for a European solar panel manufacturer achieved:

- 92% operational uptime

- 15,000 tons annual output

- 0.05mm/m straightness consistency

Another project in bridge construction utilized 60-meter-long customized angles, reducing assembly time by 300 labor-hours per structure.

Operational Economics and Upkeep Strategies

Analysis of 50 steel angle roll forming machine companies reveals:

- Preventive maintenance cycles every 400 operating hours

- Typical ROI period: 18–24 months

- 30% lifetime cost reduction through smart lubrication systems

Innovations from Angle Steel Roll Forming Machine Companies

Leading steel angle roll forming machine factories now incorporate AI-driven predictive maintenance and hybrid drive systems. Recent advancements include laser-guided alignment achieving 99.8% profile consistency and IoT-enabled machines transmitting real-time performance data to plant ERP systems. These developments position the technology for 7.8% annual market growth through 2030.

(steel angle roll forming machine)

FAQS on steel angle roll forming machine

Q: What factors should be considered when choosing an angle steel roll forming machine company?

A: Prioritize experience, customization capabilities, and after-sales support. Verify certifications and client reviews to ensure reliability. Also, assess production capacity and technical expertise.

Q: How do steel angle roll forming machine factories ensure product durability?

A: Factories use high-grade materials like hardened steel rollers and precision engineering. Regular maintenance protocols and quality control checks during manufacturing further enhance durability.

Q: Can angle steel roll forming machine companies customize machines for specific profiles?

A: Yes, most companies offer tailored solutions for unique dimensions or material grades. Provide technical specifications upfront to ensure optimal tooling and machine configuration.

Q: What quality standards do reputable steel angle roll forming machine suppliers follow?

A: Top suppliers adhere to ISO certifications and industry standards like ASTM. Third-party inspections and performance testing are often conducted to guarantee compliance.

Q: How long is the typical lead time for ordering a steel angle roll forming machine?

A: Lead times vary between 8-12 weeks, depending on customization and factory workload. Suppliers usually provide timelines after finalizing design requirements.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025