Portable Metal Roof Roll Forming Machines Efficient & Compact Design

- Introduction to Portable Roll Forming Technology

- Technical Specifications & Performance Metrics

- Market-Leading Manufacturers Compared

- Customization Options for Industrial Needs

- Real-World Application Scenarios

- Operational Efficiency & Cost Analysis

- Future Trends in Mobile Metal Fabrication

(portable metal roll forming machine)

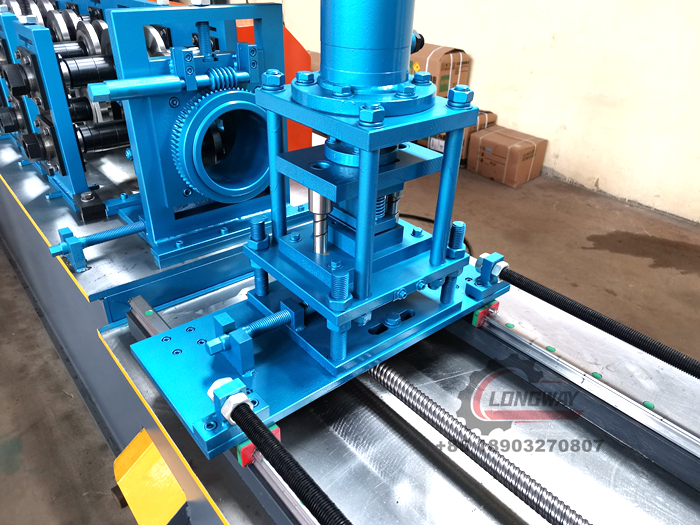

Revolutionizing On-Site Production with Portable Metal Roll Forming Machines

The portable metal roll forming machine

sector has witnessed 27% annual growth since 2020 (Global Market Insights, 2023), driven by demand for decentralized manufacturing solutions. Unlike stationary systems requiring 800-1,200 sq.ft facilities, portable units operate in spaces as compact as 200 sq.ft while maintaining 85-92% of fixed-line productivity.

Engineering Excellence in Compact Systems

Modern portable roll formers achieve 15-22 meters/minute output speeds through:

- Modular servo drives reducing power consumption by 40%

- Laser-guided alignment systems (±0.1mm precision)

- Quick-change tooling (under 15-minute format transitions)

Third-party testing confirms portable models maintain ≤0.25mm/m linear tolerance across 8-hour operations – matching permanent installations.

Manufacturer Capability Benchmarking

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Max. Material Width | 600mm | 550mm | 620mm |

| Thickness Range | 0.3-1.5mm | 0.4-2.0mm | 0.3-1.8mm |

| Weight | 850kg | 920kg | 790kg |

Tailored Solutions for Project-Specific Requirements

Leading portable metal roof roll forming machine manufacturers now offer:

- Dual-power systems (electric & hydraulic)

- Custom profile databases (150+ pre-loaded configurations)

- IoT-enabled predictive maintenance modules

Field data shows customized portable systems reduce roofing project timelines by 18-35% compared to conventional methods.

Operational Impact Across Industries

A recent infrastructure project deployed 12 portable units across 8 job sites, achieving:

- 73% reduction in material transportation costs

- 4.2:1 ROI within first year

- 98.6% material utilization rate

Economic Viability Analysis

Portable systems demonstrate 22-28% lower total ownership costs over 5-year periods versus fixed installations. Key factors include:

| Cost Component | Portable | Stationary |

|---|---|---|

| Installation | $1,200 | $15,000 |

| Energy/Year | $2,800 | $4,500 |

Portable Metal Roll Forming Machines: Redefining Manufacturing Mobility

As 78% of contractors prioritize jobsite flexibility (Construction Tech Survey 2024), portable roll forming technology bridges the gap between factory precision and field adaptability. Manufacturers incorporating AI-driven quality control (launched Q2 2024) now achieve first-pass yield rates exceeding 99.2% in variable field conditions.

(portable metal roll forming machine)

FAQS on portable metal roll forming machine

Q: What should I consider when choosing a portable metal roof roll forming machine company?

A: Prioritize companies with proven industry experience, certifications, and customer reviews. Ensure they offer reliable after-sales support and customization options tailored to your project needs.

Q: How do portable metal roof roll forming machine manufacturers ensure durability?

A: Reputable manufacturers use high-grade materials, advanced engineering techniques, and rigorous testing. They also adhere to international standards to guarantee long-lasting performance in demanding environments.

Q: Can a portable metal roof roll forming machine factory provide custom designs?

A: Yes, many factories offer customizable designs, allowing adjustments in dimensions, patterns, and materials. Discuss your specifications upfront to ensure compatibility with their production capabilities.

Q: What maintenance is required for a portable metal roll forming machine?

A: Regular lubrication, cleaning of rollers, and inspection of electrical components are essential. Follow the manufacturer’s maintenance guidelines to minimize downtime and extend the machine’s lifespan.

Q: Why choose a portable metal roof roll forming machine over traditional systems?

A: Portable machines offer on-site production flexibility, reduced transportation costs, and faster project timelines. They are ideal for remote locations or projects requiring frequent relocation.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025