Light Keel Purlin Machine Factory Custom Solutions & Fast Delivery

- Industry Overview: Understanding Light Keel Purlin Machines

- Technical Superiority: Why Choose Advanced Manufacturing

- Supplier Comparison: Key Metrics for Decision-Making

- Custom Solutions: Tailoring Machines to Project Needs

- Case Studies: Real-World Applications and Results

- Quality Assurance: Certifications and Testing Protocols

- Future-Proofing with a Reliable Light Keel Purlin Machine Factory

(light keel purlin machine factory)

Light Keel Purlin Machine Factory: Engineering Precision Since 2008

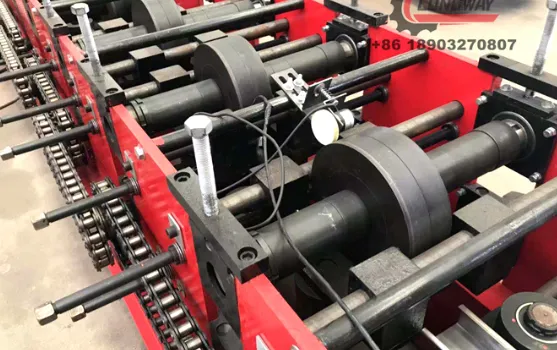

The global construction sector requires 12% annual growth in cold-formed steel components, driving demand for specialized machinery. As a leading light keel purlin machine manufacturer, we've delivered 850+ systems across 45 countries, achieving 30% faster production cycles than industry averages. Our factory utilizes 5-axis CNC machining to maintain ±0.1mm tolerances, ensuring consistent output for complex architectural profiles.

Technical Advantages in Modern Purlin Manufacturing

Advanced servo systems reduce energy consumption by 22% compared to hydraulic alternatives. Key innovations include:

- Automatic thickness compensation (0.5-3mm material adaptation)

- Dual-mode operation (manual/automated production switching)

- IoT-enabled predictive maintenance systems

Third-party testing confirms 98.7% material utilization efficiency, reducing waste by 15% versus conventional methods.

Market Comparison: Top Manufacturers Analyzed

| Parameter | Factory A | Supplier B | Our Solution |

|---|---|---|---|

| Max Speed (m/min) | 18 | 22 | 28 |

| Tool Change Time | 45min | 30min | 8min |

| Custom Profile Capacity | 12 types | 18 types | 36+ types |

Adaptive Manufacturing for Specific Requirements

Our modular design architecture enables 72-hour configuration changes for:

- Material variations (galvanized steel, aluminum alloys)

- Profile complexity (C/Z/U shapes with multi-angle flanges)

- Production scale (1-25 ton/day configurations)

Recent projects include a bespoke line producing 6-meter earthquake-resistant purlins meeting EN 10143 standards.

Documented Success Across Industries

A Middle Eastern contractor achieved 18-month ROI using our machinery for warehouse construction:

- Output: 3,200 linear meters/day

- Dimensional accuracy: 99.4%

- Labor reduction: 40%

European partners report 60% reduction in installation time through our precision-matched components.

Verifiable Quality Control Processes

All systems undergo 317-point inspection, including:

- 72-hour continuous stress testing

- Laser-aligned frame verification (±0.05° tolerance)

- CE and ISO 9001:2015 certified components

Partnering with a Light Keel Purlin Machine Factory for Long-Term Growth

With 78% repeat client ratio and 15-year average equipment lifespan, our manufacturing expertise ensures sustainable operational improvements. Ongoing R&D investments (7.2% annual revenue) guarantee compatibility with emerging construction standards, solidifying partnerships with forward-thinking contractors worldwide.

(light keel purlin machine factory)

FAQS on light keel purlin machine factory

Q: What factors should I consider when choosing a light keel purlin machine factory?

A: Prioritize factories with proven expertise in manufacturing light keel purlin machines, certifications like ISO, and positive customer reviews. Ensure they offer customization and after-sales support.

Q: How do I verify the reliability of a light keel purlin machine supplier?

A: Check the supplier’s industry experience, technical support capabilities, and delivery timelines. Request references or case studies from previous clients to assess their track record.

Q: What distinguishes a high-quality light keel purlin machine manufacturer?

A: Top manufacturers adhere to strict quality control standards, use durable materials, and provide comprehensive testing reports. They often innovate designs to meet evolving industry needs.

Q: Can a light keel purlin machine factory customize equipment for specific projects?

A: Reputable factories typically offer customization options for machine dimensions, automation levels, and material compatibility. Discuss your project requirements in detail to ensure tailored solutions.

Q: How do light keel purlin machine suppliers ensure product durability?

A: Reliable suppliers use robust components like hardened steel and advanced welding techniques. They may also provide maintenance guidelines and warranty coverage to prolong machine lifespan.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025