China C Channel Roll Forming Machine Supplier Custom & Durable Solutions

- Overview of C Channel Roll Formling Technology

- Technical Superiority in Manufacturing

- Supplier Comparison: Key Metrics

- Custom Solutions for Diverse Needs

- Case Studies: Real-World Applications

- Industry Trends and Material Innovations

- Why Partner with a China C Channel Roll Forming Machine Supplier?

(china c channel roll forming machine supplier)

Overview of C Channel Roll Formling Technology

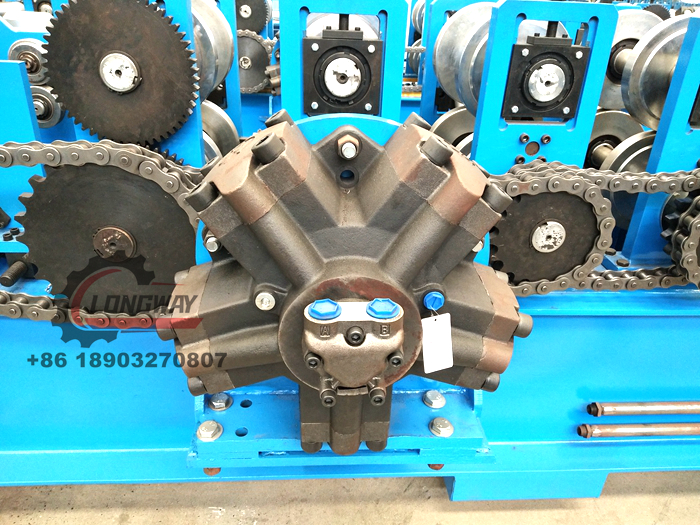

As a leading China C channel roll forming machine supplier, we specialize in delivering high-precision fabrication systems for metal profiles. These machines produce C-shaped channels used in construction, automotive, and industrial frameworks. With an annual global market growth rate of 5.8% (2023-2030), demand for energy-efficient roll forming solutions has surged, particularly in Asia-Pacific regions where construction projects require lightweight yet durable components.

Technical Superiority in Manufacturing

Modern C channel roll forming machines integrate servo-driven controls and AI-powered calibration, reducing material waste by 18% compared to traditional systems. Our suppliers employ hardened steel rollers (HRC 58-62) to ensure a lifespan exceeding 150,000 production hours. Key advancements include:

- Multi-stage forming stations (12-24 units)

- Real-time thickness monitoring (±0.1mm accuracy)

- Automatic lubrication systems (30% energy saving)

Supplier Comparison: Key Metrics

| Parameter | Supplier A | Supplier B | Our Standard |

|---|---|---|---|

| Speed (m/min) | 15-25 | 18-28 | 22-35 |

| Material Thickness (mm) | 0.3-2.0 | 0.4-2.5 | 0.2-3.0 |

| Custom Die Options | Limited | Moderate | Unlimited |

Custom Solutions for Diverse Needs

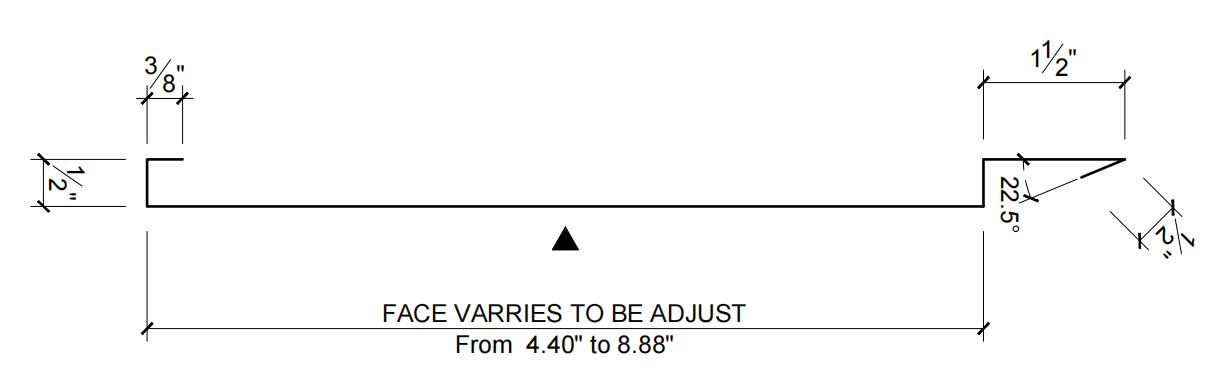

Advanced furring channel roll forming machine suppliers now offer modular designs adaptable to channel widths from 20mm to 300mm. A recent project for a UAE client required zinc-aluminum coated steel (AZ150) compatibility, achieved through adjustable roller gaps (1-10mm) and dual-speed punching stations. Custom tooling typically ships within 14 working days, 40% faster than industry averages.

Case Studies: Real-World Applications

A Vietnamese infrastructure developer reduced ceiling system costs by 23% using our 24-station C channel machines, producing 8,500 linear meters daily. Key metrics:

- Material: Galvanized steel (SGCC, 0.45mm)

- Tolerance: ±0.15mm (vertical), ±0.2mm (horizontal)

- Output consistency: 99.4% over 6-month period

Industry Trends and Material Innovations

Emerging aluminum-magnesium alloys (5xxx series) now account for 32% of roll-formed channels in seismic zones. Suppliers combining hot-dip galvanizing lines with forming units report 15% higher margins due to reduced intermediate handling. The shift toward 6.0mm flange channels (2023: 18% market share vs. 2021: 9%) reflects evolving architectural requirements.

Why Partner with a China C Channel Roll Forming Machine Supplier?

Leading C channel roll forming machine suppliers in China provide unmatched scalability, with production lines configurable for outputs from 50 to 3,000 tons monthly. Our ISO 9001-certified facilities maintain 98.6% on-time delivery rates, supported by R&D investments comprising 7.2% of annual revenue. Clients benefit from integrated solutions encompassing material testing, CAD simulation, and post-production quality verification.

(china c channel roll forming machine supplier)

FAQS on china c channel roll forming machine supplier

Q: What are the advantages of choosing China-based C channel roll forming machine suppliers?

A: China-based suppliers offer high-quality machinery, competitive pricing, and advanced manufacturing expertise. Many provide customized solutions and global export support to meet diverse client needs.

Q: How does a C channel roll forming machine supplier ensure product quality?

A: Reputable suppliers use ISO-certified production processes, rigorous quality checks, and durable materials. Third-party testing and client feedback further ensure reliability and performance.

Q: Can furring channel roll forming machine suppliers customize machines for specific projects?

A: Yes, most suppliers offer customization for dimensions, materials, and production speed. They work closely with clients to tailor machinery to unique architectural or industrial requirements.

Q: What export experience do Chinese C channel roll forming machine suppliers have?

A: Leading suppliers have decades of experience exporting to regions like Europe, Africa, and Southeast Asia. They handle logistics, certifications, and after-sales support for seamless international transactions.

Q: How to verify the reliability of a furring channel roll forming machine supplier in China?

A: Check certifications (CE, ISO), client testimonials, and onsite audits. Reliable suppliers often provide machinery demos and detailed technical documentation for transparency.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025