China Trapezoidal Roll Sheet Forming Machine Supplier High Precision & Efficiency

- Introduction to china trapezoidal roll sheet forming machine

- Technical superiority of trapezoidal sheet roll forming solutions from China

- Comparative analysis of leading manufacturers

- Customization and tailored production options

- Application scenarios and real-world examples

- Performance evaluation and maintenance perspectives

- Conclusion: Maximizing efficiency with china trapezoidal roll sheet forming machine technologies

(china trapezoidal roll sheet forming machine)

Introduction to Advanced China Trapezoidal Roll Sheet Forming Machine Technologies

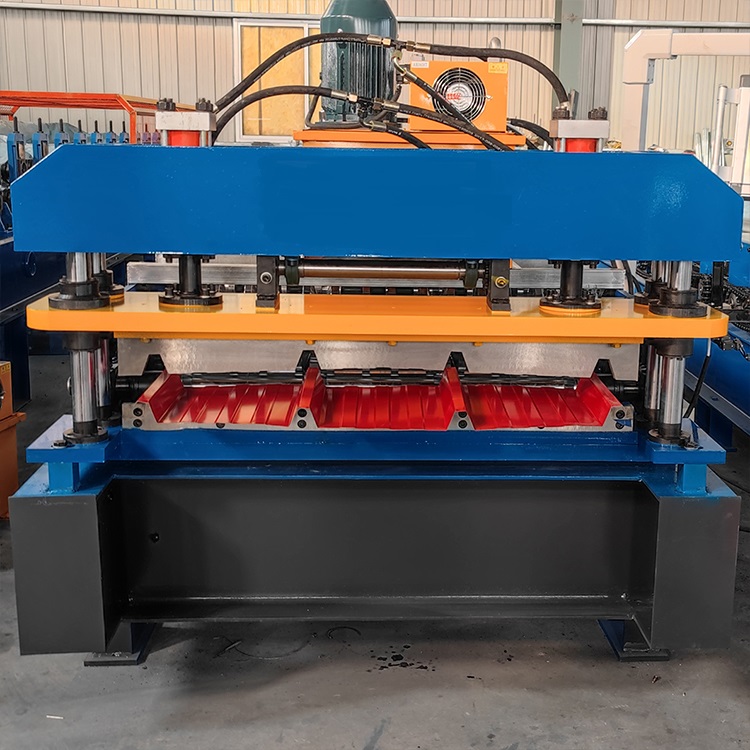

In the evolving landscape of construction and roofing material production, the china trapezoidal roll sheet forming machine has become pivotal for manufacturers seeking efficiency, precision, and durability. These sophisticated machines are responsible for producing high-strength, precision-engineered trapezoidal metal sheets suited for diverse applications, including industrial, commercial, and residential roofing systems. As the global demand for lightweight and durable construction materials grows, China emerges as a dominant exporter, providing state-of-the-art equipment that meets rigorous international standards.

The increasing use of trapezoidal sheet roll forming machine company products is driven by their reliability and cost performance. By 2023, the global market size for metal forming equipment exceeded USD 7 billion, with China contributing over 35% of worldwide exports in this sector. This surge is attributed to rapid technological advancements, competitive pricing, and stringent quality control maintained by leading Chinese manufacturers.

Technical Advantages of Trapezoidal Sheet Roll Forming Machines

Principally, china trapezoidal sheet roll forming machine lines offer outstanding technical features that distinguish them from competing solutions. Such machines are designed for continuous, high-speed operation, delivering output rates of up to 45 meters per minute while maintaining superior sheet uniformity and minimal wastage rates below 1.5%. The integration of multi-station rollers, servo feeding technology, and automated stacking modules ensures reduced manual intervention and seamless workflow.

Advanced machines employ computer-aided design (CAD) interfaces and programmable logic controllers (PLC) that enable versatile profiling with extreme precision – with tolerance variations within ±0.1mm. This degree of accuracy ensures the resulting trapezoidal sheets are perfectly matched for contemporary construction specifications. Furthermore, major manufacturers invest in high-grade chromium alloy rollers and corrosion-resistant treatment, extending tool life cycles well beyond industry averages, with some reporting up to 60,000 operating hours before major maintenance.

Manufacturer Benchmarking: Analyzing Leading Trapezoidal Sheet Roll Forming Sources

When selecting a trapezoidal sheet roll forming machine company, it is critical to appraise the key competitors in the market. The following table presents a comparative analysis of top-tier companies recognized for their product innovation, technical support, and after-sales service.

| Company Name | Location | Annual Production Capacity (Units) | Sheet Thickness Range (mm) | Max Line Speed (m/min) | Warranty Period (years) | Global Installations |

|---|---|---|---|---|---|---|

| Sinorock Machinery | Tianjin, China | 1,200 | 0.3-1.5 | 45 | 2 | 950+ |

| Botou Xianfa | Cangzhou, China | 950 | 0.4-1.2 | 35 | 1.5 | 700+ |

| Wuxi Techwell | Wuxi, China | 850 | 0.2-1.7 | 38 | 2 | 670+ |

| Hangzhou Rollforming | Hangzhou, China | 600 | 0.3-2.0 | 40 | 2 | 400+ |

These manufacturers uphold international quality certifications (ISO, CE) and offer tailored after-sales support, remote diagnostics, and operator training programs. The choice among them should consider project-specific needs and expected usage volume.

Customization: Flexible Solutions for Unique Production Needs

Not all sheet production lines fit standard project requirements. Modern china trapezoidal sheet roll forming machine suppliers provide wide-ranging customization options that address the unique challenges of clients worldwide. These solutions start with CAD-based design consultations that adjust the roll tooling profile, line length, and accessory integration based on the intended sheet profile and raw material properties.

Available customizations include adjustable width settings (from 500mm up to 1,250mm), profile depth alterations, the integration of automatic punching, embossing, or cutting units, and even fully enclosed, dust-free operation. For factories processing high-tensile galvanized steel or color-coated coils, specialist rollers and reinforced frame constructions assure perfect form and structural consistency.

Additionally, digital control systems can be configured for multi-profile switching, supporting up to 12 profiles on a single machine with recipe memory functionality—minimizing downtime when operating within demanding, multi-contract manufacturing environments.

Application Spectrum and Global Success Cases

The application suite of china trapezoidal roll sheet forming machine stretches across a panorama of industries. In the building sector, these machines produce roofing and wall cladding systems for logistics warehouses, aircraft hangars, sports complexes, and residential buildings. A prime example includes the implementation in the "Green City Logistic Center" (Shanghai, 2022), where over 380,000 square meters of trapezoidal sheets were supplied using fully automated roll forming lines, streamlining project delivery by 34%.

Infrastructure projects—such as high-speed rail station shelters and highway noise barriers—also leverage their advantages. In 2021, a leading European construction group sourced 17 custom-configured trapezoidal sheet roll forming machines from two major Chinese manufacturers, permitting simultaneous production of insulated and perforated panels for a 240,000 square meter project.

Additionally, energy sector investments, notably solar farm panel supports and wind turbine tower shielding, utilize trapezoidal profiles for both aerodynamic efficiency and weather resistance. From rapid-deployment military shelters in Central Asia to cost-optimized containers and agricultural buildings in Africa, product versatility is underscored by data showing over 3 million metric tons of trapezoidal sheet output attributed to Chinese equipment annually.

Performance Metrics and Optimized Maintenance

Quantitative performance evaluation of modern trapezoidal sheet roll forming machine company offerings revolves around metrics such as uptime factor (commonly exceeding 98.2%), sheet dimensional stability, and energy consumption per ton produced (often as low as 22 kWh/ton). These indicators surpass several global benchmarks and contribute to reduced total cost of ownership.

Preventive maintenance protocols rank highly, including online diagnostic systems that monitor roller wear, hydraulic fluid state, and line vibrations in real time. Predictive component replacement alerts, based on machine learning algorithms analyzing past maintenance logs, mitigate risks of unplanned downtime. The adoption of modular design also ensures faster part replacement, with average changeover times as short as 45 minutes for critical assemblies.

As environmental requirements intensify, most machines incorporate energy-efficient servo drives and closed-loop fluids. Compliance with EU Ecodesign and RoHS directives is standard for exports. Data transparency through integrated SCADA systems enables plant managers to optimize workflow and detect bottlenecks instantly, maximizing throughput and enhancing consistency batch after batch.

Conclusion: Maximizing Efficiency with China Trapezoidal Roll Sheet Forming Machine Innovation

The global construction ecosystem continues its rapid transformation, and with it, the role of china trapezoidal roll sheet forming machine technology remains pivotal. By combining cutting-edge technical features, broad customization capabilities, and extensive industry application, these machines address the full spectrum of productivity, precision, and sustainability demands.

Whether addressing massive infrastructure projects or niche architectural requirements, Chinese manufacturers present not only highly productive equipment but also reliable long-term support—confirmed by an ever-expanding footprint of real-world installations worldwide. Investing in a next-generation china trapezoidal sheet roll forming machine ensures robust profitability, reduced operational risks, and compliance with increasingly stringent industry standards, securing a competitive edge in sheet metal production throughout the upcoming decade.

(china trapezoidal roll sheet forming machine)

FAQS on china trapezoidal roll sheet forming machine

Q: What is a China trapezoidal roll sheet forming machine?

A: A China trapezoidal roll sheet forming machine is equipment designed to manufacture trapezoidal-shaped metal roofing and cladding sheets. These machines are widely used in the construction and building industries. They offer precise forming, high efficiency, and durability.

Q: Why should I choose a China trapezoidal sheet roll forming machine?

A: China trapezoidal sheet roll forming machines are known for their high quality, reliability, and cost-effectiveness. Many companies in China offer advanced technology and customization to meet various needs. They are also supported by professional after-sales services.

Q: How to select a reliable trapezoidal sheet roll forming machine company in China?

A: Look for a company with a strong reputation, proven experience, and good customer reviews. It’s important to check if they provide technical support and custom solutions. Certifications and after-sales service are also key factors.

Q: What materials can be processed by a China trapezoidal roll sheet forming machine?

A: These machines can process various materials such as galvanized steel, color steel, and aluminum. Material thickness and width compatibility depend on specific machine models. Consult the manufacturer for exact material specifications.

Q: What maintenance does a trapezoidal roll sheet forming machine require?

A: Regular cleaning, lubrication, and timely inspection of critical components are essential for optimal performance. Most trapezoidal sheet roll forming machine companies provide detailed maintenance guidelines. Proper maintenance increases the machine’s lifespan and efficiency.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025