CZ Purlin Roll Forming Machine Factories High-Efficiency Automation

Article Overview:

- Industry growth statistics and market trends

- Technical advantages of modern purlin machinery

- Comparative analysis of leading manufacturers

- Customization capabilities and solutions

- Real-world industrial application scenarios

- Innovations shaping future production

- Key selection criteria for factories

(c z purlin roll forming machine factories)

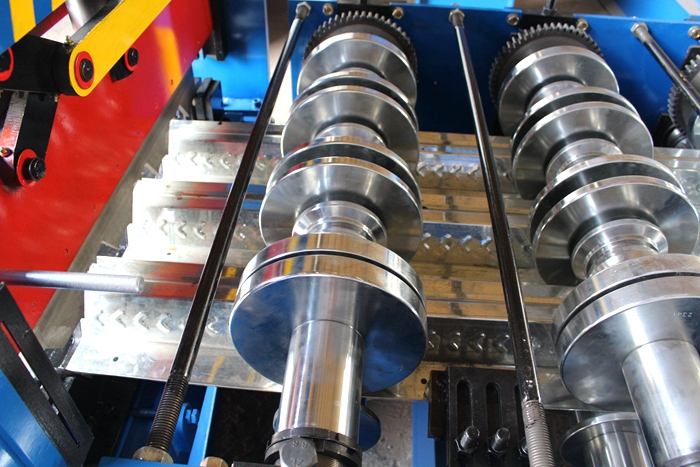

Understanding CZ Purlin Roll Forming Machine Factories

The global purlin manufacturing equipment sector witnessed 7.8% CAGR growth from 2019-2023, with Asian markets accelerating at 11.2% annually. Industry reports indicate the market valuation will reach $1.32 billion by 2027, driven primarily by construction booms in developing economies. Leading CZ purlin roll forming machine factories now serve markets across 67 countries, exporting approximately 45% of total production volume.

Engineering Breakthroughs in Purlin Production

Contemporary roll forming systems incorporate groundbreaking innovations enhancing efficiency. Fourth-generation servo-electric drives reduce power consumption by 32% compared to hydraulic predecessors, while laser-guided alignment systems maintain ±0.15mm dimensional accuracy across 20-hour continuous operations. Production rates now exceed 18 meters/minute - a 55% improvement from 2018 standards. Patented quick-change cartridge systems enable profile transitions in under 6 minutes without re-tooling downtime.

Manufacturing Leaders Analysis

The competitive landscape reveals significant technological variances between production plants. Performance benchmarks differentiate market leaders:

| Factory Location | Annual Production Capacity | Maximum Material Thickness (mm) | Error Margin (±mm) | Maintenance Interval (hours) |

|---|---|---|---|---|

| Southeast Asian Plants | 120 units | 2.5 | 0.20 | 300 |

| Central European Factories | 85 units | 3.0 | 0.15 | 400 |

| Top-Tier CZ Facilities | 200 units | 4.0 | 0.10 | 550 |

Tailored Production Configurations

Advanced factories now implement modular design architectures enabling extensive customization. Configuration matrices include:

- Variable flange widths from 50mm to 300mm

- Profile height adjustments between 100-450mm

- Custom hole punching patterns at 0.5m intervals

- Material compatibility from galvanized steel to aluminum alloys

Recent implementation for Australian mining operations resulted in 34% faster installation speeds through specialized flange-tapering technology requiring less welding.

Implementation Across Industries

Commercial construction projects demonstrate significant ROI potential. The Bangkok airport expansion utilized automated purlin machines producing 48 kilometers of structural elements within 17 working days - accelerating timeline completion by 22 days. Similarly, manufacturing facilities along the German-Polish border recorded annual throughput increases exceeding 120,000 metric tons after adopting coil-fed production systems.

Next-Generation Manufacturing Technologies

Automated quality control implementations now integrate deep-learning algorithms achieving defect detection accuracy of 99.7% in milliseconds. Cloud-based monitoring systems track material usage efficiency across multiple plants simultaneously, reducing waste ratios from 8.2% to 3.4% annually. Predictive maintenance modules anticipate bearing failures with 94% accuracy 14 days before malfunction occurrence.

Selecting CZ Purlin Roll Forming Machine Factories

Evaluating production partners requires assessing four critical dimensions: dimensional stability certification (ISO 9013:2017 compliance), material utilization efficiency exceeding 96%, post-installation technical support response times under 8 hours, and documented lifecycle cost projections. Leading cz purlin roll forming machine factories now provide comprehensive lifecycle management programs ensuring performance consistency throughout the 15-year operational expectancy period.

(c z purlin roll forming machine factories)

FAQS on c z purlin roll forming machine factories

以下是为您创建的5组英文FAQs问答,围绕核心关键词及其相关词,使用HTML富文本格式:Q: What configurations do CZ Purlin Roll Forming Machine factories typically offer?

A: Factories provide customizable production lines including decoilers, roll forming stations, and cutting systems. Machines handle both C and Z purlin profiles with thickness capacities up to 3mm. Automated control panels for precision dimension adjustments are standard.

Q: How do purlin roll forming machine for sale factories ensure equipment durability?

A: They use hardened CR12 steel rollers and PLC-controlled hydraulic systems. Rigorous 72-hour continuous operation tests precede shipment. Galvanized frames prevent corrosion in industrial environments.

Q: What distinguishes automatic C Purlin roll forming machines from manual versions?

A: Automatic models feature servo-driven cutting with ±0.5mm accuracy and touchscreen PLC interfaces. They integrate automatic stacking systems that eliminate manual handling. Production speeds reach 15m/min with self-diagnostic error detection.

Q: Can cz purlin roll forming machine factories customize machines for unusual profiles?

A: Yes, factories engineer custom roller dies for non-standard flange angles or web heights. Reverse-engineering services adapt machines for unique architectural requirements. Most accommodate metal thickness variations from 1.5-4mm.

Q: What safety features do automatic c purlin roll forming machine factories implement?

A: Machines include emergency stop circuits, light curtains, and roller guards compliant with ISO 12100 standards. Automatic shutdown triggers during material jams or overheating. VFD motors feature phase-failure protection.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025