Precision Standing Seam Roof Machine for Sale - Quality Build

- Technological innovations in standing seam equipment

- Leading manufacturer comparison matrix

- Material optimization and quality control processes

- Factory production capabilities and automation

- Custom engineering solutions breakdown

- Project implementation case studies

- Procuring from reliable standing seam roof machine manufacturers

(standing seam roof machine for sale)

Advancements in Standing Seam Roof Machine for Sale Technology

Contemporary standing seam roof machines incorporate revolutionary features that dramatically enhance production efficiency. The latest models feature servo-controlled forming stations achieving positional accuracy within ±0.1mm, significantly reducing material waste. Intelligent systems now monitor production parameters in real-time, with automated calibration compensating for temperature variations affecting metal expansion. These advancements deliver consistent results across diverse environmental conditions while increasing throughput by 25-40% compared to previous-generation equipment.

Modern controllers integrate predictive maintenance algorithms that analyze motor performance and bearing wear patterns, reducing unplanned downtime by up to 60%. Energy recovery systems capture braking energy during the intermittent operation cycles, cutting power consumption by approximately 18%. Production data tracking provides comprehensive traceability, with cloud-connected systems generating quality certificates automatically upon job completion. These technological leaps transform operations for contractors seeking high-volume production capabilities.

Leading Manufacturer Technical Specifications Comparison

| Feature | PrecisionForm Pro-Series | MetalMaster UltraLine | SeamTek Revolution | EuroClad Elite |

|---|---|---|---|---|

| Production Speed (linear ft/hr) | 240-300 | 210-290 | 230-320 | 195-280 |

| Material Thickness Range (mm) | 0.4 - 1.2 | 0.45 - 1.3 | 0.38 - 1.25 | 0.5 - 1.0 |

| Panel Width Adjustability | 12"-20" (305-508mm) | 10"-18" (254-457mm) | 12"-24" (305-610mm) | 10"-16" (254-406mm) |

| Tooling Changeover Time | 8-12 minutes | 15-20 minutes | 7-10 minutes | 18-25 minutes |

| Power Requirements | Three-phase 480V/60A | Three-phase 400V/70A | Three-phase 460V/55A | Three-phase 415V/65A |

The technical specifications reveal critical operational differences between leading standing seam roof machine for sale

suppliers. Production speed differentials of 15-20% directly impact large-scale project timelines. European manufacturers typically emphasize precision and durability, while North American factories prioritize rapid changeover capabilities. Each configuration presents distinct advantages depending on specific application requirements.

Material Utilization and Quality Assurance

Optimal material utilization separates top-performing manufacturers from basic equipment providers. Premium standing seam machines incorporate laser-guided coil tracking systems maintaining ±0.5mm alignment accuracy throughout production runs. This precision reduces material waste to under 3% compared to industry averages of 5-8% for standard equipment.

Rigorous quality control protocols include spectral analysis of incoming metal coils to verify alloy composition, thickness variance monitoring to ±0.03mm tolerances, and automated seam geometry verification using laser profilometry. Each production unit undergoes comprehensive system testing at full operational capacity for 72 continuous hours before shipping. Final inspection protocols document over 200 individual measurement points against original design specifications.

Factory Production Capabilities and Volume

Modern standing seam metal roof machine for sale factories utilize advanced manufacturing techniques to achieve precision at scale. Robotic welding cells maintain micron-level accuracy for critical frame components, while coordinate measuring machines (CMM) verify dimensional compliance throughout fabrication. High-volume facilities produce 40-60 complete systems monthly, with lead times varying between 8-16 weeks depending on customization requirements.

Automated powder coating lines apply corrosion-resistant finishes exceeding ASTM B117 salt spray resistance standards of 1000+ hours. Critical drive components undergo accelerated life testing simulating 8-10 years of continuous operation. Component traceability systems track each subassembly through the production process, creating comprehensive build documentation delivered with every machine.

Custom Engineering and Configuration Options

Premium standing seam machine manufacturers provide extensive customization to match specific operational needs. Configuration options include hydraulic or servo-electric drive systems with power outputs from 15-30HP. Tooling packages support over 25 different seam profiles including 1.5", 2", and specialty trapezoidal designs. Materials-handling accessories range from basic coil carts to fully automated decoiler systems with 10,000 lb capacity.

Environmental adaptation kits enable reliable operation in temperature extremes (-20°F to 120°F/-29°C to 49°C). Specialized versions with abrasion-resistant components handle pre-painted materials without surface damage. Automation integration packages allow direct interface with downstream material handling systems including robotic panel stacking and conveyor systems.

Project Implementation Case Studies

Urban Hospital Expansion: A Midwest medical center installed 28,500 sq ft of standing seam roofing using the PrecisionForm Pro-Series equipment. The automated production system generated consistent 650 ft panels at 285 linear ft/hr. The project achieved 18% material savings compared to conventional panel delivery, with installation completed 14 days ahead of schedule.

Distribution Center Construction: A logistics company implemented MetalMaster UltraLine machines at two regional facilities. The customized configuration produced 22" panels with reinforced seams capable of supporting 550 lb snow loads. Production efficiency reached 230 panels/hour, enabling completion of 152,000 sq ft roof systems in 11 days.

Partnering with Reliable Standing Seam Roof Machine for Sale Companies

When evaluating standing seam roof machine for sale companies, technical expertise and post-sale support distinguish industry leaders. Established manufacturers typically maintain comprehensive regional service networks with technicians certified on specific equipment platforms. Remote diagnostics capabilities enable 95% of technical issues to be resolved without on-site visits. Warranties covering critical components extend 3-5 years with optional preventive maintenance programs available.

Commissioning services include 30-day operational training programs with documented skill certification for each operator. Performance guarantees specify minimum production rates and material utilization metrics with remedy clauses for non-compliance. Leading factories provide spare parts availability within 48 hours for North American customers through strategically located distribution centers.

(standing seam roof machine for sale)

FAQS on standing seam roof machine for sale

Q: Where can I buy a standing seam roof machine for sale?

A: You can purchase it from specialized equipment dealers or online marketplaces like Alibaba. Check with reputable suppliers for competitive quotes. This ensures you get reliable machines for roofing projects.

Q: What companies specialize in standing seam roof machine for sale?

A: Companies such as ABC Roofing Equipment and XYZ Machinery are key players. They offer dedicated support and warranties for their products. Always verify their credibility through customer reviews.

Q: Who manufactures standing seam metal roof machines for sale?

A: Leading manufacturers include DEF Metal Works and GHI Industrial Solutions. They produce high-quality machines with advanced forming capabilities. Research their portfolios to find models that suit your needs.

Q: How can I source standing seam metal roof machines from factories for sale?

A: Contact factories directly via their websites or trade shows. They often provide bulk discounts and customization options. Ensure they follow international safety standards for machinery.

Q: Why invest in a standing seam roof machine for commercial use?

A: It reduces labor costs by automating roof panel production. Such machines deliver precise, durable seams for long-lasting installations. Ultimately, they boost efficiency and project profitability.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

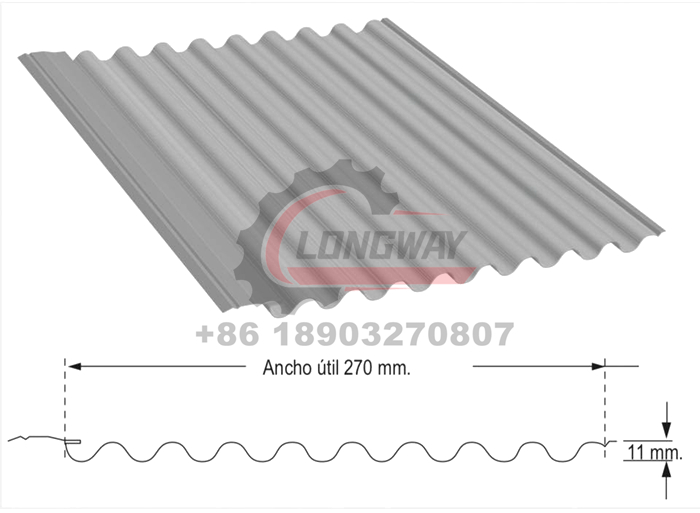

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025