Full Auto C Z Purlin Roll Forming Machine - High Efficiency & Precision

In the dynamic landscape of modern construction, efficiency, precision, and material optimization are paramount. The ability to rapidly produce high-quality structural components is a key differentiator for manufacturers and builders alike. Central to this revolution in prefabricated construction is the **Full Auto C Z purlin Roll forming machine**, a sophisticated piece of industrial equipment that has reshaped the fabrication of lightweight, robust structural members.

This comprehensive guide delves into the intricate world of these machines, exploring their technological prowess, diverse applications, and the compelling advantages they offer. We aim to provide an authoritative resource, blending technical insights with practical applications, designed to empower industry professionals and stakeholders with the knowledge needed to make informed decisions.

Industry Trends and the Rise of Automated Purlin Production

The global construction industry is experiencing a significant shift towards modular and pre-engineered building solutions. Driven by demands for faster project completion, reduced on-site labor, improved safety, and cost-effectiveness, the adoption of light gauge steel framing and pre-fabricated components has surged. According to a report by Grand View Research, the global pre-engineered buildings market size was valued at USD 24.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 11.2% from 2023 to 2030. This growth directly fuels the demand for high-efficiency roll forming solutions.

Within this context, purlins – horizontal beams used for supporting the rafters or roof deck – are critical structural elements. Traditionally, purlins were often produced manually or with less efficient methods, leading to inconsistencies, slower production, and higher material waste. The advent of the **Full Auto C Z purlin Roll forming machine** has revolutionized this process by enabling continuous, high-speed, and precise production of C and Z shaped purlins, which are highly favored for their excellent strength-to-weight ratio and ease of assembly.

Modern industry trends emphasize smart manufacturing, Industry 4.0 integration, and sustainable practices. Fully automated roll forming machines are at the forefront of this evolution, incorporating advanced PLC (Programmable Logic Controller) systems, HMI (Human-Machine Interface) touchscreens, and even IoT (Internet of Things) capabilities for remote monitoring and diagnostics. This technological integration not only enhances productivity but also significantly reduces human error, optimizes material usage, and contributes to a more sustainable construction ecosystem.

Understanding the Full Auto C Z Purlin Roll Forming Machine: Core Technology and Manufacturing Process

A **Full Auto C Z purlin Roll forming machine** is an integrated system designed to convert flat metal coils into complex C and Z profiles through a series of precision forming rollers. The "full auto" aspect signifies its capability for continuous, hands-off operation from coil feeding to finished product cutting, often including automated size changes and punching.

Product Specifications and Technical Parameters

To appreciate the capabilities of a modern **Full Auto C Z purlin Roll forming machine**, understanding its key specifications is crucial. These parameters directly influence production capacity, material compatibility, and the precision of the final product.

| Parameter | Typical Range/Description | Technical Significance |

|---|---|---|

| Material Thickness | 1.5 - 3.5 mm (0.06 - 0.14 inches) | Determines the gauge of steel the machine can process. Thicker material requires more robust rollers and higher power. |

| Material Type | Galvanized Steel, Pre-painted Steel, Cold-rolled Steel (G250-G350 MPA) | Machine design must accommodate material strength and surface properties to prevent damage. |

| Purlin Web Height (C/Z) | 80 - 300 mm (3.15 - 11.8 inches) | Defines the range of purlin sizes the machine can produce. Critical for structural design versatility. |

| Flange Width | 30 - 100 mm (1.18 - 3.94 inches) | Impacts load-bearing capacity and connection methods. |

| Lip Height | 10 - 30 mm (0.39 - 1.18 inches) | Provides rigidity to the purlin profile. |

| Forming Speed | 15 - 35 m/min (49 - 115 ft/min) | Directly affects production volume and efficiency. Higher speeds require more precise control systems. |

| Roller Stations | 16 - 20 forming stations | More stations allow for gradual, precise forming, reducing material stress and ensuring higher accuracy. |

| Main Motor Power | 15 - 30 kW (20 - 40 HP) | Power required to drive the forming rollers, especially for thicker materials and higher speeds. |

| Hydraulic Power | 5.5 - 11 kW (7.5 - 15 HP) | Powers punching and cutting mechanisms, ensuring strong, clean cuts. |

| Control System | PLC with HMI Touch Screen (e.g., Siemens, Panasonic) | Enables automated operation, precise control over parameters, diagnostics, and data logging. |

| Cutting Method | Hydraulic Post-cutting / Pre-cutting (non-stop) | Post-cutting is common; non-stop flying shear improves efficiency by cutting on-the-fly. |

| Roll Material | Cr12MoV, GCr15 (Quenched and Tempered, HRC58-62) | High-grade tool steel or bearing steel, heat-treated for extreme hardness and wear resistance, crucial for long lifespan. |

| Shaft Material | 45# Carbon Steel (Heat treated, tempered) | Provides strength and rigidity to support the rollers under heavy loads. |

| Machine Dimension (L*W*H) | Approx. 10m x 2m x 1.8m (variable) | Footprint requirement for factory planning. |

| Weight | Approx. 10 - 15 Tons (variable) | Indicates the robust construction required for stability and performance. |

Detailed Manufacturing Process of the Machine Itself

The construction of a **Full Auto C Z purlin Roll forming machine** is a testament to precision engineering. The quality and lifespan of the machine are heavily dependent on the materials and manufacturing processes employed:

- Frame Construction: The machine base and frame are typically constructed from high-strength structural steel, often welded using advanced techniques to ensure rigidity and stability, crucial for vibration reduction and maintaining alignment during high-speed operation.

- Roller Manufacturing (Critical Component):

- Material Selection: Rollers, which are the heart of the forming process, are usually made from premium tool steels such as Cr12MoV or GCr15 (equivalent to AISI D2 or 52100 bearing steel). These materials are chosen for their exceptional wear resistance and toughness.

- Precision Machining: The profiles of the rollers are precisely machined using high-accuracy CNC machining centers. This ensures that each roller profile matches the exact design specifications, allowing for a smooth and accurate forming process. Tolerances are often within microns (e.001mm) to guarantee seamless material flow and consistent purlin quality.

- Heat Treatment: Post-machining, the rollers undergo rigorous heat treatment processes, including quenching and tempering. This process hardens the steel to achieve a surface hardness of HRC 58-62, significantly extending the rollers' operational life and preventing premature wear, even under continuous heavy loads.

- Surface Finishing: Some rollers may undergo additional surface treatments like hard chrome plating or nitriding to further enhance wear resistance and reduce friction, improving both the quality of the formed purlin and the efficiency of the machine.

- Shaft and Bearing Assembly: The shafts supporting the rollers are typically made from high-grade 45# carbon steel (equivalent to AISI 1045), precision ground and heat-treated for optimal strength and concentricity. High-quality bearings (e.g., SKF, FAG equivalents) are used to ensure smooth rotation and minimize friction, contributing to energy efficiency and machine longevity.

- Cutting Die Manufacturing: The hydraulic cutting dies, responsible for shearing the formed purlins to length, are also made from high-strength, wear-resistant tool steel. They are precisely ground and heat-treated to ensure clean, burr-free cuts and extended service life.

- Assembly and Alignment: The entire machine is assembled in a controlled environment. Critical alignment checks are performed using laser alignment tools and precision gauges to ensure that all forming stations are perfectly aligned, which is vital for producing straight and accurate purlin profiles.

- Electrical and Control System Integration: High-quality electrical components from reputable brands (e.g., Siemens, Schneider Electric, Panasonic) are integrated. The PLC is programmed with sophisticated algorithms to manage the entire process, from decoiling speed to cutting length and automatic profile changes.

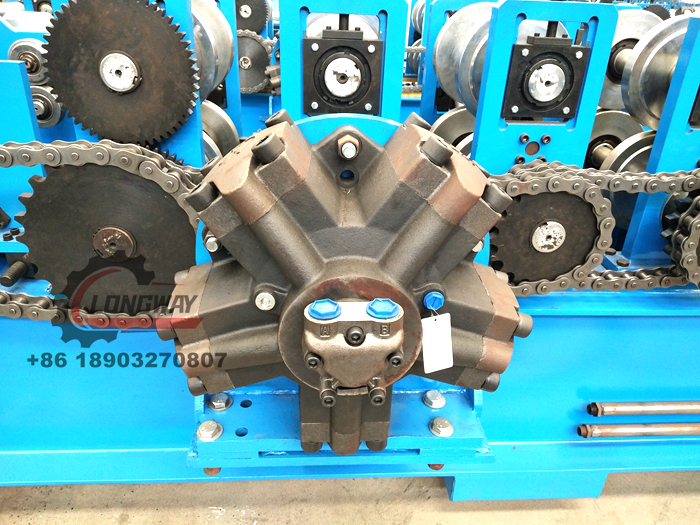

Advanced control panel and robust construction of a **Full Auto C Z purlin Roll forming machine**.

Process Flow of Purlin Production

The manufacturing process of C and Z purlins using a **Full Auto C Z purlin Roll forming machine** follows a streamlined, highly automated sequence:

- Decoiling: The process begins with loading a large coil of steel (typically galvanized or pre-painted) onto an uncoiler (decoiler). The uncoiler feeds the flat steel strip into the machine. Modern decoilers are often hydraulic, with automatic tension control to ensure smooth and consistent material flow.

- Guiding and Leveling: Before forming, the steel strip passes through a guiding mechanism and sometimes a leveling device to ensure it enters the roll former straight and flat, removing any coil set or minor imperfections.

- Punching/Pre-punching (Optional): If required, holes for bolts or fasteners are pre-punched into the flat strip before forming. This is often done by a hydraulic punching unit integrated into the line. Pre-punching ensures precise hole placement regardless of the final purlin length and avoids deformation that can occur with post-punching on a formed profile.

- Roll Forming: This is the core of the process. The flat steel strip is progressively shaped by passing through a series of precisely designed roller dies. Each station incrementally bends the metal closer to the desired C or Z profile. The number of stations (typically 16-20) ensures a gradual forming process, minimizing stress on the material and preserving its structural integrity and surface finish.

- Automatic Size and Profile Change (Key Automation Feature): A distinguishing feature of a **Full Auto C Z purlin Roll forming machine** is its ability to automatically change between C and Z profiles and adjust dimensions (web height, flange width, lip height) without manual intervention. This is achieved through a sophisticated hydraulic and servo-motor system controlled by the PLC, which adjusts the position of the roller shafts and forming tools in minutes, significantly reducing downtime compared to older, manual adjustment machines.

- Cutting: Once the purlin reaches the desired length, it is automatically cut by a hydraulic shearing device. For high-speed production, a "flying shear" mechanism is used, which cuts the purlin while it is still moving, ensuring continuous production without stopping the roll former.

- Output and Stacking: The finished purlins are then conveyed to an output table or an automatic stacking system, ready for packaging, storage, or immediate use.

The intricate roll forming stations, precisely engineered for seamless profile creation.

Application Scenarios and Strategic Advantages

The versatility and efficiency of the **Full Auto C Z purlin Roll forming machine** make it indispensable across a wide spectrum of industries and construction applications. Its products are fundamental to modern structural frameworks.

Applicable Industries

The C and Z purlins produced by these machines are crucial in:

- Construction Industry: This is the primary sector, including commercial buildings, industrial warehouses, factories, agricultural sheds, sports facilities, and residential structures (especially for roofing and wall framing). The rapid assembly capabilities of purlins directly contribute to accelerated project timelines.

- Infrastructure Projects: Used in bus shelters, railway platforms, and other public utility structures where lightweight yet robust frameworks are needed.

- Logistics and Storage: For building large-span distribution centers and storage facilities, providing reliable support for roofing and walls.

- Energy Sector: Supporting structures for solar panel installations (solar farms) and other renewable energy infrastructure due to their adaptability and strength.

- Manufacturing Facilities: Creating the internal framework for workshops and production halls, offering flexible design for heavy machinery placement.

Advantages in Typical Application Scenarios

The advantages offered by purlins produced on a **Full Auto C Z purlin Roll forming machine** are manifold, impacting project economics, structural integrity, and environmental sustainability:

- High Production Efficiency and Speed: A single machine can produce several tons of purlins per hour, significantly accelerating project timelines. For instance, a typical machine operating at 25 m/min can produce approximately 1500-2000 linear meters of purlins per 8-hour shift, depending on length. This translates to a drastic reduction in manufacturing lead times compared to traditional methods.

- Precision and Consistency: Automated control systems (PLC) ensure that every purlin is produced to exact specifications with minimal deviation. This precision is critical for structural integrity and ease of assembly on site, reducing construction errors and rework. ISO 9001 quality management systems ensure consistent output.

- Material Optimization and Cost Savings:

- Reduced Waste: The automated cutting and forming process minimizes scrap material.

- Optimal Design: C and Z purlins offer an excellent strength-to-weight ratio, meaning less steel is needed to achieve the required structural performance compared to heavier hot-rolled sections. This can lead to steel savings of 10-20% on a project.

- Energy Efficiency (indirect): Lighter structures require less foundation work and transport energy, contributing to overall project energy savings.

- Versatility and Flexibility: The ability to produce both C and Z profiles, and quickly change dimensions, means one machine can cater to diverse project requirements. Z purlins are particularly versatile for overlapping, creating continuous beam effects over multiple spans, while C purlins are ideal for simpler connections.

- Enhanced Durability and Longevity: When made from galvanized steel, the purlins exhibit excellent corrosion resistance, crucial for long-term performance in various environmental conditions, from coastal areas to industrial zones. The precise forming process also maintains the integrity of the coating.

- Streamlined On-site Assembly: Pre-punched holes and consistent dimensions mean purlins can be rapidly bolted together on site, significantly reducing labor costs and construction time. This 'kit-of-parts' approach minimizes complex welding or fabrication at the construction site.

A complete production line featuring the **Full Auto C Z purlin Roll forming machine**.

Technical Advantages and Innovation Leadership

Beyond basic functionality, leading **Full Auto C Z purlin Roll forming machine** manufacturers integrate cutting-edge technologies to deliver superior performance, reliability, and ease of use.

Key Innovations Driving Performance

- Advanced PLC Control Systems: Modern machines utilize industrial-grade PLCs (e.g., from Siemens, Rockwell, Mitsubishi) that manage every aspect of the operation with unparalleled precision. This includes speed synchronization, automatic length measurement, punching pattern control, and error diagnostics. HMI touchscreens provide intuitive control and real-time feedback, empowering operators with comprehensive control.

- Quick Changeover Technology: This is perhaps the most significant innovation. Rather than manual adjustments taking hours or even a full shift, advanced machines can switch between C and Z profiles and change dimensions (e.g., from C100 to Z200) in under 10 minutes, thanks to servo-motor driven adjustments and pre-programmed parameters. This drastically increases operational flexibility and reduces downtime, making small-batch production economically viable.

- Non-Stop Flying Shear Cutting: For maximum throughput, a flying shear system ensures that the purlin is cut to length while the machine is still running at full speed. This eliminates the need to stop the roll former for each cut, enhancing productivity significantly, especially for shorter purlin lengths.

- Precision Punching Solutions: Integrated pre-punching units with multiple punching tools can create complex hole patterns (e.g., slot holes, round holes, custom patterns) at high speed and accuracy before the profile is formed. This ensures perfect hole alignment and avoids material distortion. Some systems even allow for dynamic punching pattern changes on the fly.

- Optimized Roller Design and Material Science: Continuous R&D into roller design minimizes material spring-back, ensuring consistent angles and dimensions. The use of advanced materials (Cr12MoV, GCr15) for rollers and shafts, combined with specialized heat treatment processes (vacuum quenching), extends component lifespan significantly, reducing maintenance and replacement costs.

- Remote Diagnostics and IoT Integration: Top-tier machines can be equipped with remote monitoring capabilities, allowing manufacturers to diagnose issues, provide software updates, and offer technical support from anywhere in the world. This minimizes on-site service calls and reduces potential downtime.

The intuitive control system and robust frame of a **Full Auto C Z purlin Roll forming machine**.

Manufacturer Comparison and Selection Guide

Choosing the right **Full Auto C Z purlin Roll forming machine** involves more than just looking at the price tag. It requires a holistic evaluation of the manufacturer's capabilities, product quality, and after-sales support. Here’s a guide to help prospective buyers:

Key Evaluation Criteria for Manufacturers

- Technological Prowess and R&D Investment: Look for manufacturers who actively invest in research and development. This indicates a commitment to innovation, leading to more efficient, reliable, and technologically advanced machines. Inquire about their patent portfolio related to roll forming technology.

- Manufacturing Quality and Standards Compliance:

- Certifications: Reputable manufacturers will hold international certifications such as ISO 9001 for quality management and CE marking for European market compliance, demonstrating adherence to strict quality and safety standards.

- Material Quality: Inquire about the source and type of steel used for critical components like rollers, shafts, and frame. High-grade materials (e.g., Cr12MoV, GCr15 for rollers; 45# steel for shafts) are non-negotiable for machine longevity and performance.

- Precision Machining: Understand their machining capabilities. Do they use advanced CNC machinery for component fabrication? This is vital for achieving the tight tolerances required for precision forming.

- After-Sales Service and Support:

- Technical Support: Availability of experienced technicians for troubleshooting, installation, and commissioning.

- Spare Parts Availability: Ensure easy access to spare parts with reasonable lead times.

- Warranty and Guarantees: A comprehensive warranty (e.g., 1-2 years for main components) signifies manufacturer confidence in their product.

- Training: Provision of operator and maintenance training is essential for maximizing machine uptime and extending its lifespan.

- Customization Capabilities: Can the manufacturer tailor the machine to your specific needs? This might include unique profile requirements, higher speeds, integration with existing production lines, or specific automation features.

- Industry Experience and Reputation: How long has the manufacturer been in the roll forming industry? What is their track record? Customer testimonials, case studies, and site visits (if possible) can provide valuable insights into their reliability and service quality. Look for manufacturers with a proven track record of successful installations globally.

Company Background and Service Commitment (Example: LW Roll Forming Machine)

As a leading provider in the industry, LW Roll Forming Machine exemplifies dedication to quality and customer satisfaction. With years of specialized experience in designing and manufacturing advanced roll forming equipment, LW has established a global footprint, delivering machines to diverse markets including Europe, North America, Southeast Asia, and Africa. Our commitment is underpinned by:

- Expertise: Our engineering team possesses deep knowledge in mechanical design, automation, and material science, ensuring our **Full Auto C Z purlin Roll forming machine**s are at the forefront of technology.

- Quality Assurance: Adherence to strict quality control protocols, from raw material inspection to final machine testing, ensures every unit meets international standards like ISO 9001 and CE.

- Comprehensive Support: We provide end-to-end support, including pre-sales consultation, custom machine design, installation and commissioning, operator training, and reliable after-sales service. Our typical delivery cycle for a standard machine ranges from 45 to 75 working days, depending on customization, followed by meticulous packaging for international shipment.

- Trustworthiness: We offer a standard 12-month warranty on main mechanical components and 6 months on electrical components, with lifetime technical support. Our customer support team is available for remote assistance, troubleshooting, and dispatching spare parts efficiently.

Customization Solutions for Unique Project Requirements

While standard **Full Auto C Z purlin Roll forming machine** models offer broad utility, specific projects often necessitate bespoke solutions. Leading manufacturers understand this and offer extensive customization capabilities.

Common customization options include:

- Profile Design Flexibility: Ability to produce non-standard C or Z purlin profiles, or even completely new custom profiles required for specialized architectural or structural designs. This might involve custom-designed roller sets.

- Material Handling Capacity: Adapting the machine to handle wider or thicker coil materials, or different types of steel alloys, requiring stronger uncoilers, heavier-duty forming stations, and enhanced cutting mechanisms.

- Integrated Punching Solutions: More complex punching patterns, including multiple hole sizes, varying distances, or even custom cut-outs, integrated directly into the pre-punching unit. This is critical for complex modular construction systems.

- Production Speed Optimization: Tailoring the machine's speed to match specific production targets, which may involve higher motor powers, advanced servo drives, or more robust cutting solutions (e.g., high-speed flying shears).

- Automation Level Enhancement: Adding features like automatic coil loading, robotic stacking and bundling, inline inkjet printing for labeling, or full integration into a centralized factory management system (MES - Manufacturing Execution System).

- Energy Efficiency Solutions: Incorporating energy-saving drives (e.g., VFDs - Variable Frequency Drives), optimized hydraulic systems, or regenerative braking for further reductions in operational costs.

- Environmental Adaptations: Designing machines for operation in specific environmental conditions, such as extreme temperatures, high humidity, or corrosive atmospheres, which might require special coatings or sealed components.

Application Cases and Success Stories (General Examples)

The impact of the **Full Auto C Z purlin Roll forming machine** can be seen in countless successful projects worldwide:

- Large-Span Industrial Warehouse Construction: A major logistics company in Southeast Asia utilized a customized high-speed **Full Auto C Z purlin Roll forming machine** to produce all the purlins for a new 50,000 square meter distribution center. The machine's ability to quickly switch between C and Z profiles and automatically adjust dimensions allowed for efficient production of thousands of purlins daily, significantly shortening the steel structure fabrication timeline by 30%. This project demonstrated the machine's capability to handle large-scale demands while maintaining precision, contributing to a structurally sound and rapidly deployed facility.

- Agricultural Building Expansion in North America: A large agricultural cooperative invested in a versatile **Full Auto C Z purlin Roll forming machine** to produce purlins for multiple barn and storage facility expansions across their properties. The machine's quick changeover feature was invaluable, allowing them to produce various purlin sizes (e.g., C150 for smaller sheds, Z200 for large barns) on demand. This in-house capability not only reduced material procurement costs by 20% but also provided unparalleled flexibility, allowing them to respond quickly to new construction needs without relying on external suppliers.

- Modular Housing Development in Europe: For a project involving the rapid construction of affordable modular homes, a specialized **Full Auto C Z purlin Roll forming machine** with integrated precision punching was deployed. The machine produced purlins with custom hole patterns that perfectly aligned with the modular panels, ensuring seamless assembly on site. This streamlined process reduced on-site labor requirements by 25% and accelerated the completion of each housing unit, demonstrating the machine's role in advancing modern, prefabricated construction methodologies.

Quality Assurance, Trustworthiness, and After-Sales Support

The credibility and reliability of a **Full Auto C Z purlin Roll forming machine** supplier are as important as the machine's technical specifications. Trustworthiness is built on robust quality assurance, transparent processes, and unwavering customer support.

Commitment to Quality and Standards

Reputable manufacturers adhere to stringent international quality and safety standards:

- ISO 9001 Certification: This globally recognized standard for quality management systems ensures that the manufacturer has systematic processes in place to consistently meet customer and regulatory requirements. This covers design, production, installation, and servicing.

- CE Marking: For machines destined for the European market, CE marking signifies conformity with European health, safety, and environmental protection standards. This is a legal requirement and demonstrates a commitment to user safety and environmental responsibility.

- Material Certifications: Steel materials used in the machine's construction (frame, shafts, rollers) should come with material certificates, guaranteeing their chemical composition and mechanical properties. This ensures the foundational integrity and durability of the machine.

- Pre-Shipment Inspection (PSI): Before delivery, a comprehensive PSI is conducted, including running test production, checking all electrical and hydraulic systems, and verifying dimensions and tolerances of formed profiles. This ensures the machine is fully operational and meets all specified parameters upon arrival.

Delivery Cycle and Logistics

The typical delivery cycle for a **Full Auto C Z purlin Roll forming machine** can vary based on customization and production schedule, but generally ranges from 45 to 75 working days from order confirmation to ex-factory readiness. This period accounts for:

- Design & Engineering: Tailoring the machine to specific client requirements.

- Component Sourcing & Manufacturing: Production of rollers, shafts, frame, electrical panels, and hydraulic systems.

- Assembly & Testing: Rigorous assembly followed by comprehensive testing and quality control checks, including a full trial run.

- Packaging & Logistics Preparation: Machines are carefully packaged (e.g., plastic film, wooden cases for delicate parts) to ensure safe international transport.

Warranty and Customer Support

A strong warranty and reliable customer support are hallmarks of a trustworthy supplier:

- Warranty Promise: Most reputable manufacturers offer a warranty period, typically 12-24 months for main mechanical components (e.g., frame, main motor, gearboxes, rollers) and 6-12 months for electrical parts (e.g., PLC, sensors, inverters). This covers manufacturing defects and component failures under normal operating conditions.

- Lifetime Technical Support: Beyond the warranty period, ongoing technical support is usually provided. This can include phone support, email consultation, and remote diagnostics, ensuring long-term operational peace of mind.

- Spare Parts Supply: Availability of genuine spare parts is crucial. Manufacturers should maintain an inventory of common wear parts and have efficient processes for custom part fabrication if needed.

- On-Site Service and Training: For installation and commissioning, many suppliers dispatch experienced engineers to the client's facility to oversee setup, conduct initial test runs, and provide comprehensive training for operators and maintenance staff. This hands-on training ensures that the client's team is fully proficient in operating and maintaining the machine efficiently.

Professional FAQ for Full Auto C Z Purlin Roll Forming Machine

Q1: What is the typical lifespan of the rollers in a **Full Auto C Z purlin Roll forming machine**?

The lifespan of rollers largely depends on the material, heat treatment, and volume of production. High-quality rollers made from Cr12MoV or GCr15 steel, properly heat-treated to HRC 58-62, can last for 5-10 years or more under normal operating conditions, forming millions of linear meters of purlins. Regular maintenance, proper lubrication, and avoiding processing materials outside the specified thickness range are crucial for maximizing their lifespan.

Q2: Can the machine produce both C and Z profiles automatically without manual intervention?

Yes, a true **Full Auto C Z purlin Roll forming machine** is designed for automatic profile changeover. This means the machine's PLC system, combined with servo-motorized or hydraulic adjustments, can reconfigure the roller positions to switch between C and Z profiles and adjust dimensions (web height, flange width, lip height) automatically within minutes, often less than 10 minutes. This significantly reduces downtime and labor costs compared to older manual systems.

Q3: What types of materials can this machine process?

The machine is primarily designed to process various types of steel coils, including galvanized steel (GI), pre-painted galvanized steel (PPGI), and cold-rolled steel. The specific grade of steel (e.g., G250, G300, G350 MPa yield strength) and thickness range (typically 1.5mm to 3.5mm) must be compatible with the machine's design specifications to ensure optimal performance and prevent damage.

Q4: What is the importance of the number of forming stations?

The number of forming stations (typically 16-20) is crucial for the quality and precision of the final purlin profile. More stations allow for a more gradual and gentle bending process. This progressive forming minimizes stress on the material, prevents micro-cracks in the steel or coating, reduces spring-back, and ensures a highly accurate and consistent profile without excessive deformation. It also extends the lifespan of the rollers by distributing the forming load.

Q5: What are the main safety standards and features integrated into the machine?

Safety is paramount. Reputable machines comply with international safety standards like CE. Key safety features include emergency stop buttons strategically located, safety guards and enclosures around moving parts, overload protection for motors, light curtains or sensors to detect human presence in hazardous zones, and proper electrical grounding. The control system also includes fault detection and diagnostic capabilities to prevent operational hazards.

Q6: How does the machine ensure the dimensional accuracy of the purlins?

Dimensional accuracy is ensured through several integrated systems. The PLC (Programmable Logic Controller) precisely controls the speed of the uncoiler and the roll former. An encoder measures the length of the formed purlin with high precision, triggering the cutting mechanism at the exact desired length. The precise design and CNC machining of the rollers, along with a sufficient number of forming stations, minimize material spring-back and ensure consistent profile dimensions (web height, flange width, lip height) throughout the production run.

Q7: What is "flying shear" cutting and why is it important?

"Flying shear" cutting is a highly efficient cutting method where the hydraulic cutting mechanism moves synchronously with the continuously forming purlin, making the cut without stopping the main roll forming machine. This non-stop operation significantly increases production speed and efficiency, especially when producing shorter purlin lengths or high volumes. It contrasts with "stop-and-cut" methods that require the machine to halt for each cut, reducing overall throughput.

Conclusion: Paving the Way for Future Construction

The **Full Auto C Z purlin Roll forming machine** stands as a cornerstone of modern, efficient, and sustainable construction. Its ability to produce high-quality, precision-engineered C and Z purlins at high speeds, coupled with unparalleled automation and versatility, makes it an indispensable asset for any steel structure fabrication enterprise. From optimizing material usage and reducing labor costs to accelerating project timelines and enhancing structural integrity, these machines deliver tangible benefits across the entire construction value chain.

As the construction industry continues its trajectory towards greater industrialization and prefabrication, the demand for advanced roll forming solutions will only intensify. Investing in a state-of-the-art **Full Auto C Z purlin Roll forming machine** is not just an equipment purchase; it's a strategic decision that positions businesses at the forefront of innovation, driving efficiency, profitability, and leadership in a competitive market.

By understanding the intricate details of their operation, the robust engineering behind them, and the comprehensive support provided by leading manufacturers, stakeholders can confidently leverage this technology to build faster, stronger, and more sustainably for the future.

References and Further Reading:

- Grand View Research. (2023). _Pre-Engineered Buildings Market Size, Share & Trends Analysis Report_. Available from industry market research reports. (Specific URL not provided as it's a paid report, but represents typical industry data sources).

- Roll Forming Institute. (n.d.). _Roll Forming Process Basics_. Retrieved from https://www.rollforming.org/education/rollforming-process-basics/

- Steel Construction Institute (SCI). (n.d.). _Light Gauge Steel Sections_. (Information on structural applications and benefits of cold-formed steel). For general academic reference, consider checking publications on the SCI website: https://www.steel-sci.com/

- ISO. (n.d.). _ISO 9001 - Quality Management_. Retrieved from https://www.iso.org/iso-9001-quality-management.html

- European Commission. (n.d.). _CE Marking_. Retrieved from https://ec.europa.eu/growth/single-market/ce-marking_en

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025