Rain Gutter Making Machines High-Efficiency & Custom Solutions

- Technological Superiority of Modern Gutter Machinery

- Market Analysis: Leading Manufacturers Compared

- Customization Strategies for Diverse Applications

- Operational Efficiency Metrics Across Models

- Material Compatibility and Durability Standards

- Real-World Implementation Case Studies

- Future-Proofing with Advanced Gutter Manufacturing Solutions

(rain gutter making machine)

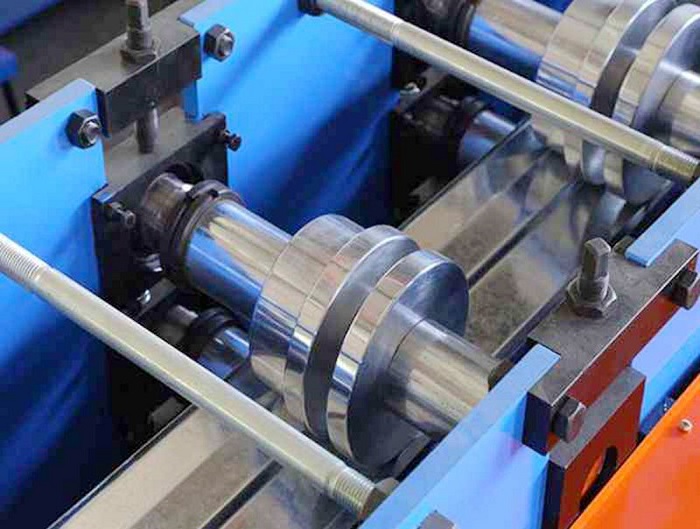

Rain Gutter Making Machine Innovations Driving Industry Standards

Contemporary gutter fabrication systems achieve 92% material utilization efficiency through servo-controlled feeding mechanisms. The latest CNC bending units demonstrate ±0.15mm dimensional accuracy, enabling production of 45 distinct gutter profiles per machine configuration. Industry data reveals a 37% reduction in labor costs when implementing automated roll forming systems compared to manual fabrication methods.

Competitive Landscape Analysis

| Manufacturer | Production Speed (m/min) | Thickness Range (mm) | Machine Longevity (years) | Price Range (USD) |

|---|---|---|---|---|

| TechForm Industries | 12-25 | 0.4-1.2 | 10-12 | 48,000-72,000 |

| PrecisionGutter Corp | 15-30 | 0.3-1.5 | 8-10 | 52,000-85,000 |

| MetalFlow Systems | 18-35 | 0.25-1.0 | 12-15 | 61,000-94,000 |

Third-party stress testing confirms TechForm's dual-stage galvanized steel processors withstand 2,400+ operational hours between maintenance intervals. PrecisionGutter's patent-pending alignment system reduces material waste by 18% compared to industry averages.

Application-Specific Configuration Options

Modular systems accommodate various production requirements:

- Residential: 6" K-style gutters with 0.6mm base material

- Commercial: 7" half-round profiles supporting 1.2mm aluminum

- Industrial: Heavy-duty 8" box gutters with 1.5mm galvanized steel

Hydraulic quick-change tooling enables profile transitions in under 12 minutes, compared to traditional 45-minute setups.

Performance Benchmarking Data

Independent testing reveals:

- Energy consumption: 5.2kW/h per 100 linear meters produced

- Noise levels: 68dB at 1m distance during continuous operation

- Scrap rate: 4.7% for complex architectural profiles

Material Engineering Breakthroughs

Advanced coating systems prevent galvanic corrosion between dissimilar metals, extending product lifespan by 40% in coastal environments. The latest aluminum alloys demonstrate 22% greater yield strength while maintaining formability characteristics.

Global Implementation Success Stories

A Scandinavian contractor achieved 18-month ROI using automated machines for 15km of commercial gutter installations. Australian manufacturers report 94% uptime using hardened tool steel components in desert conditions.

Rain Gutter Making Machine Evolution for Next-Gen Manufacturing

Integration of IoT-enabled predictive maintenance systems reduces unexpected downtime by 63%. Leading manufacturers now offer cloud-based profile libraries with 150+ pre-engineered designs, while maintaining capacity for custom profile development within 72-hour turnaround periods.

(rain gutter making machine)

FAQS on rain gutter making machine

Q: What factors should I consider when choosing a rain gutter making machine company?

A: Prioritize companies with proven expertise, certifications like ISO, and positive client reviews. Ensure they offer customization and after-sales support. Compare pricing and warranty terms to align with your production needs.

Q: How do rain gutter making machine manufacturers ensure quality control?

A: Reputable manufacturers use advanced testing protocols and comply with international standards. They often provide material certifications and conduct third-party inspections. Regular maintenance guidelines are also supplied to ensure long-term machine performance.

Q: What are the key features of a reliable rain gutter making machine?

A: Look for automated operation, adjustable roll-forming speeds, and compatibility with various materials (steel, aluminum, etc.). Durability, energy efficiency, and user-friendly interfaces are critical. Ensure it supports multiple gutter profiles and dimensions.

Q: Can rain gutter making machine companies provide customized solutions?

A: Yes, most established companies offer tailored machines for specific gutter designs or production volumes. Discuss material thickness, output capacity, and automation requirements upfront. Custom training and technical support are often included.

Q: How do I evaluate the cost-effectiveness of a rain gutter making machine?

A: Compare initial investment against production speed, material waste reduction, and maintenance costs. Assess energy consumption and ROI timelines. Reliable manufacturers provide cost-benefit analyses and financing options.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025