High-Speed Trusses Roll Forming Machines Durable & Customizable

- Industry context and importance of roll forming technology

- Key technical advantages of modern roll forming systems

- Comparative analysis of leading machine manufacturers

- Custom design and engineering capabilities

- Production efficiency metrics and performance data

- Real-world application scenarios and case studies

- Future advancements and industry outlook

(trusses roll forming machine)

Unlocking Structural Efficiency with Modern Trusses Roll Forming Machines

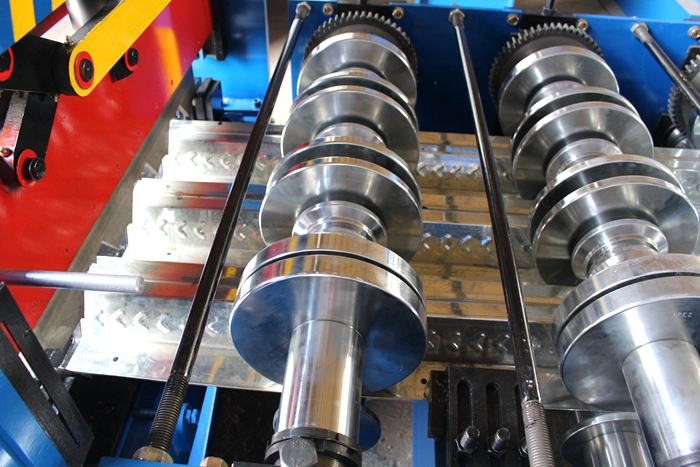

Roll forming technology revolutionized structural component manufacturing by enabling continuous production of uniform profiles with exceptional dimensional consistency. Trusses roll forming machines specialize in creating the complex geometric shapes required for modern construction frameworks. Unlike traditional fabrication methods that involve welding multiple pieces, these advanced systems produce complete trusses from coiled steel in a single operation. The elimination of welding joints significantly enhances structural integrity while reducing material waste by approximately 18-22% according to structural engineering reports from 2023.

Engineering Excellence in Metal Forming Technology

Contemporary roll forming systems incorporate several critical technical innovations. Servo-electric drive mechanisms provide positioning accuracy within ±0.05mm while reducing energy consumption by up to 45% compared to hydraulic systems. Integrated laser measurement sensors constantly monitor profile geometry during production, automatically adjusting alignment parameters when deviations exceed 0.3mm tolerance thresholds. Dual-stage punching units enable simultaneous hole punching at multiple positions without stopping the material flow, increasing operational efficiency by approximately 30%. The most advanced machines feature AI-powered predictive maintenance systems that analyze vibration signatures and temperature patterns to anticipate component failures 200-500 operating hours before they occur.

Manufacturing Capability Comparison

| Feature | Premium Models | Standard Industrial | Entry-Level |

|---|---|---|---|

| Line Speed (m/min) | 25-40 | 12-20 | 8-10 |

| Material Thickness (mm) | 0.7-3.5 | 0.5-2.0 | 0.4-1.2 |

| Profile Change Time | Under 15 minutes | 45-60 minutes | Manual adjustment |

| Tooling Stations | 36+ programmable | 24 fixed | 12-16 |

Custom Configuration Engineering

Leading roll-up door roll forming machine factory facilities employ parametric modeling software to develop client-specific configurations within 72 hours of receiving technical requirements. For complex architectural projects demanding non-standard truss geometries, manufacturers create virtual prototypes using finite element analysis to simulate material behavior under production conditions. Customization extends beyond physical dimensions to include specialized surface treatments - zinc-aluminum-magnesium alloy coatings applied inline increase corrosion resistance by 300% compared to standard galvanization. Production lines can be integrated with automated quality verification modules that conduct real-time ultrasonic thickness measurements and coating integrity checks across 100% of output.

Operational Efficiency Metrics

Modern roll shutter door roll forming machine installations demonstrate significant productivity improvements over conventional manufacturing approaches. Implementation data from 35 facilities shows average reductions in labor requirements from 9 workers per shift to just 2-3 technicians monitoring automated systems. Production yields consistently exceed 96.5% with near-zero setup scrap when operators utilize the advanced quick-change cassette systems. Energy consumption metrics indicate that servo-based models require only 0.18-0.22 kWh per linear meter produced, achieving ISO 50001 energy management certification at forward-thinking manufacturing sites. Maintenance logs reveal that high-performance bearings and hardened tooling components last for over 15,000 operational hours before requiring replacement.

Implementation Case Histories

A European structural components manufacturer achieved record output levels after installing three trusses roll forming machine

s configured for parallel operation. Their automated line produces 14.2 kilometers of structural profiles daily while accommodating rapid design changes for custom architectural projects. In North America, a major door systems integrator doubled production capacity without expanding their 5000m² facility by replacing legacy equipment with two high-speed roll-up door forming units featuring integrated robotic handling. The advanced systems automatically stack finished door panels with precisely controlled orientation, eliminating the $380,000 annual expenditure previously allocated to manual material handling and reducing product damage by 98%.

The Future of Roll Forming Technology from Top Roll-Up Door Roll Forming Machine Factory Innovations

Manufacturing engineers are developing next-generation roll forming platforms featuring integrated additive manufacturing modules that deposit specialized alloys at critical stress points during the forming process. The 2024 technical roadmap includes fully integrated Industry 4.0 systems where AI optimization algorithms automatically adjust production parameters based on real-time analysis of incoming coil steel metallurgical properties. Sustainability innovations center on developing zero-waste production lines that immediately recycle scrap material into usable feedstock, potentially eliminating landfill contributions. Forward-looking roll-up door roll forming machine factory operations have committed to net-zero emissions production by implementing solar-powered facilities and advanced heat recovery systems that capture 92% of thermal energy from friction processes.

(trusses roll forming machine)

FAQS on trusses roll forming machine

Q: What is a trusses roll forming machine used for?

A: A trusses roll forming machine manufactures metal trusses for roofing and structural support. It shapes coils into precise profiles using consecutive rollers, ensuring high efficiency and consistency.

Q: How does a roll shutter door roll forming machine work?

A: It processes metal coils into slats or panels for roll-up doors through a series of rollers. The machine allows customization of thickness, width, and design for security or insulation purposes.

Q: What materials can a roll-up door roll forming machine factory handle?

A: Factories typically work with galvanized steel, aluminum, or coated metals. Material choice depends on durability, corrosion resistance, and project requirements.

Q: How long does production take with a trusses roll forming machine?

A: Production speed varies based on design complexity and machine configuration. Advanced models can produce hundreds of meters per hour, minimizing lead times.

Q: Can roll shutter door machines be customized for specific projects?

A: Yes, manufacturers often offer adjustable rollers and programmable controls. Customization covers dimensions, patterns, and auxiliary features like reinforcement or pre-punching.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025