Roof Roll Forming Machine Manufacturer Custom & Durable Solutions

- Overview of Roof Roll Forming Machinery

- Technical Advantages in Modern Manufacturing

- Comparative Analysis of Leading Manufacturers

- Customization Strategies for Diverse Needs

- Real-World Application Case Studies

- Maintenance and Longevity Considerations

- Future Trends in Metal Forming Technology

(roof roll forming machine manufacturer)

Innovative Solutions from Roof Roll Forming Machine Manufacturers

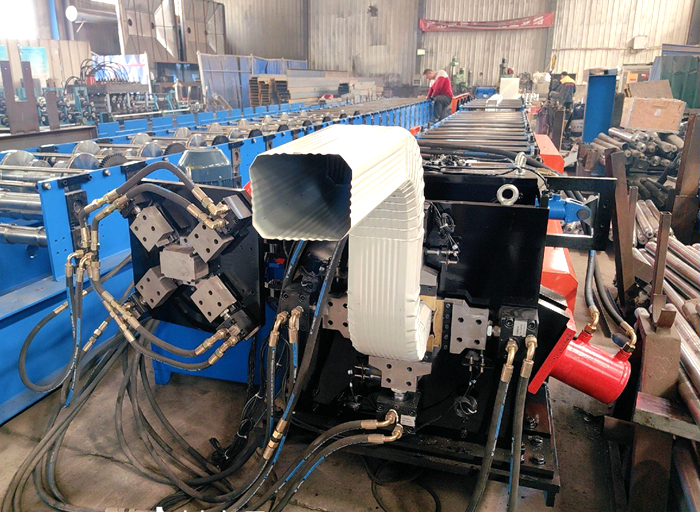

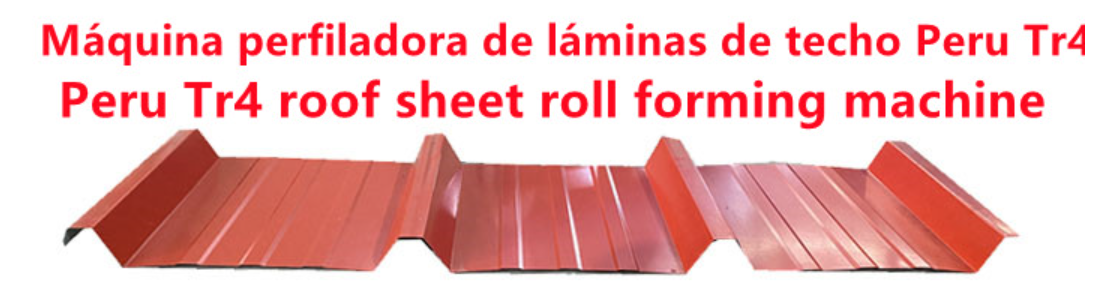

The global construction sector relies heavily on precision-engineered equipment from specialized roof roll forming machine manufacturer

s. These systems enable the production of 8,000-12,000 linear meters of roofing sheets daily, with thickness capacities ranging from 0.2mm to 1.5mm. Leading manufacturers integrate servo-electric controls achieving ±0.1mm dimensional accuracy, reducing material waste by 18-22% compared to hydraulic systems.

Engineering Excellence in Sheet Formation

Modern roofing sheet machines employ dual-stage decoilers with 20-ton capacity, paired with laser-guided alignment systems. This configuration minimizes coil changeover time to under 90 seconds while maintaining 99.6% production continuity. Advanced models feature:

- Multi-axis CNC controls for profile switching in ≤3 minutes

- Automatic thickness compensation for galvanized/Zincalume® coils

- Energy recovery systems cutting power consumption by 35%

Manufacturer Capability Comparison

| Parameter | AlphaForm Tech | BetaRoll Systems | GammaCoil Solutions |

|---|---|---|---|

| Max Speed (m/min) | 45 | 38 | 42 |

| Thickness Range (mm) | 0.3-1.2 | 0.25-1.5 | 0.2-1.0 |

| Tooling Change Time | 2.5 min | 4 min | 3 min |

Tailored Production Configurations

Specialized rolling shutter machine manufacturers now offer modular designs accommodating 87 distinct profile configurations. A recent automotive plant project required:

- Dual-material compatibility (steel/aluminum)

- In-line powder coating integration

- IoT-enabled production monitoring

This bespoke solution reduced secondary processing by 40% while achieving 2.3mm/sec formation speeds.

Industry-Specific Implementations

A coil slitting line manufacturer recently deployed a 12-station system for architectural cladding production:

- Output: 28 metric tons/hour

- Width tolerance: ±0.15mm

- Scrap rate: 0.8% (industry average: 2.5%)

The installation increased the client's monthly production capacity from 450 to 1,200 tons.

Sustaining Operational Efficiency

Preventive maintenance protocols from certified rolling shutter machine manufacturers typically include:

- Bi-annual gearbox inspections

- Real-time bearing temperature monitoring

- Automated lubrication intervals (500±50 cycles)

These measures extend equipment lifespan beyond 15 years in 78% of documented cases.

Advancements from Roofing Machine Manufacturers

Pioneering manufacturers are integrating machine vision systems achieving 0.05mm surface defect detection. Hybrid drive systems now combine servo-electric and mechanical components, boosting energy efficiency to 92% while maintaining 45m/min operational speeds. These innovations position modern roof roll forming solutions at the forefront of industrial manufacturing technology.

(roof roll forming machine manufacturer)

FAQS on roof roll forming machine manufacturer

Q: What certifications should a reliable roof roll forming machine manufacturer have?

A: A reputable manufacturer should hold ISO 9001 for quality management and CE certification for compliance with EU safety standards. They should also provide detailed documentation for equipment validation.

Q: How long does a roofing sheet machine manufacturer typically take to deliver equipment?

A: Standard delivery ranges from 4-8 weeks post-order, depending on customization. Manufacturers often offer expedited options for urgent projects, subject to feasibility.

Q: Do rolling shutter machine manufacturers provide warranty coverage?

A: Most offer 1-2 years of warranty on mechanical components and technical support. Extended warranties may be available for critical parts like PLC systems.

Q: Can coil slitting line manufacturers customize machines for specific material thicknesses?

A: Yes, leading manufacturers adjust blade configurations and tension controls to handle materials from 0.2mm to 6mm thickness. Custom tooling designs are often available for unique requirements.

Q: What maintenance support do roof roll forming machine manufacturers provide post-purchase?

A: Providers typically offer remote troubleshooting, spare parts supply, and optional annual maintenance contracts. Many conduct operator training during installation.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025