Affordable Metal Roofing Machine Cost & Top Suppliers

- The Strategic Importance of Metal Roofing Machine Cost

- Technical Innovations Driving Modern Production Efficiency

- Leading Market Players: Company and Capability Analysis

- Custom Solutions Addressing Industry-Specific Requirements

- Operational Results: Real-World Application Case Studies

- Critical Selection Criteria for Equipment Purchasing

- Future Advancements from Metal Roofing Machine Cost Manufacturers

(metal roofing machine cost)

The Strategic Importance of Metal Roofing Machine Cost

Investing in modern metal roofing machinery creates pivotal competitive advantages across the construction sector. Production budgets typically allocate 30-45% to manufacturing equipment, making cost optimization critical. Industry data indicates ROI timelines have shortened to 14-28 months for premium systems due to increasing material demand. Beyond initial purchase price, savvy buyers evaluate lifecycle expense components: energy consumption (15-20% of TCO), maintenance protocols (8-12% annually), and operational labor savings (typically 40-60%). Forward-thinking metal roofing machine cost

companies increasingly leverage predictive analytics to minimize unexpected expenses.

Technical Innovations Driving Modern Production Efficiency

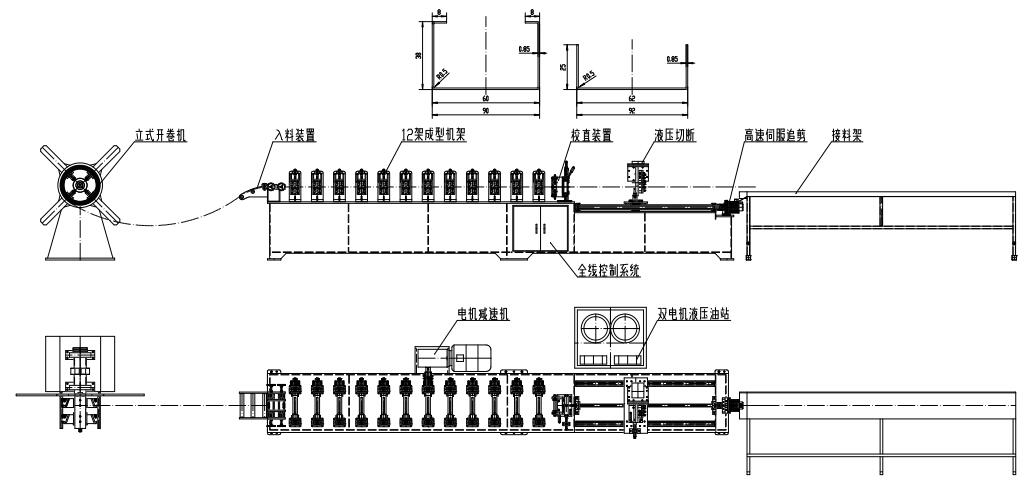

Contemporary metal roofing equipment integrates revolutionary capabilities transforming fabrication workflows. Advanced roll-forming systems achieve production speeds exceeding 80 feet per minute, increasing output by 170% compared to decade-old equipment. Integrated CNC technology maintains dimensional accuracy within 0.3mm tolerance across operations. Energy-saving innovations reduce power requirements by 22-35% through regenerative drive systems and optimized motor controls. Manufacturers now embed IoT sensors that monitor 40+ operational parameters, predicting maintenance needs before failures occur. This convergence of precision mechanics and digital intelligence directly impacts project viability.

| Technical Feature | Standard Equipment | Premium Systems | Performance Gap |

|---|---|---|---|

| Production Speed | 28-32 ft/min | 70-85 ft/min | +150% |

| Material Utilization | 87-91% | 94-97% | +7-9% |

| Changeover Time | 35-45 min | 8-12 min | -75% |

| Error Rate | 3.2-4.1% | 0.6-0.9% | -78% |

Leading Market Players: Company and Capability Analysis

Global metal roofing machinery vendors offer distinct advantages across cost segments. Established European manufacturers dominate the premium tier ($250k-$850k), delivering unmatched precision with proprietary control systems. Mid-range suppliers ($120k-$240k) increasingly compete through modular designs enabling future upgrades. Emerging manufacturers concentrate on specialized machinery like portable roll-formers ($65k-$140k) serving regional markets. Production capacity remains crucial - industry leaders maintain 6-9 week delivery schedules versus 14-22 weeks for smaller suppliers. Most reputable metal roofing machine cost companies maintain regional technical centers supporting swift component replacement.

Custom Solutions Addressing Industry-Specific Requirements

Increasingly, manufacturers develop purpose-built configurations aligning with specialized project demands. Commercial roofing contractors routinely order machinery with enhanced bending capacity for structural panels exceeding 22-gauge thickness. Modular options now allow integrating secondary processes - 58% of recent installations include in-line punching stations. Coastal region operators frequently request corrosion-resistant modifications employing marine-grade components. For prefabrication facilities, multi-profile systems processing 4-6 distinct panel styles significantly reduce changeover windows. The industry shift toward configuration flexibility means 75% of orders now incorporate some degree of customization beyond standard specifications.

Operational Results: Real-World Application Case Studies

Documented outcomes from operational machinery provide compelling validation points. A Midwest contractor reduced installation labor by 300 hours monthly after deploying high-speed equipment, recovering equipment cost in 19 months. After implementing automated panel handling, a Canadian manufacturer decreased workplace injuries by 42% year-over-year. Most significantly, Florida-based operators achieved 98% weather-tightness compliance by leveraging precision forming technology, substantially reducing callbacks. Production data shows that mid-market manufacturers typically achieve the most significant ROI when processing over 500 panels daily.

Critical Selection Criteria for Equipment Purchasing

Discerning buyers evaluate multiple factors beyond catalog specifications when sourcing equipment. Technical service accessibility dramatically impacts operational uptime - machinery with local support availability experiences 76% faster resolution times. Production scalability matters profoundly; modular systems accommodate business growth with 40-60% lower reinvestment compared to equipment replacement. Material compatibility examinations prevent costly modifications, particularly regarding coated steel formulations. Verification of safety certifications (CE, UL, ISO) remains non-negotiable, with premiums of 8-12% reflecting comprehensive compliance testing. Warranties spanning critical components for 3-5 years signal manufacturer confidence.

Future Advancements from Metal Roofing Machine Cost Manufacturers

Industry innovators currently develop transformative technologies addressing persistent challenges. Integrated AI systems achieving predictive calibration adjustments will potentially increase material utilization to 99% by 2026. Several manufacturers trial hydrogen-compatible components anticipating energy transitions. Particularly noteworthy, leading metal roofing machine cost manufacturers invest heavily in sustainable production, with prototypes reducing carbon footprints by 45% through regenerative power systems. Automation breakthroughs will likely enable single-operator panel production lines by 2028, revolutionizing labor economics. These innovations underscore how continuous advancement serves construction efficiency while maximizing equipment investment longevity.

(metal roofing machine cost)

FAQS on metal roofing machine cost

Q: What factors affect the overall metal roofing machine cost?

A: Key factors include machine type (standalone vs. integrated system), production capacity, automation level, and material thickness compatibility. Brand reputation and after-sales service also impact long-term costs.Q: Where can I find reliable metal roofing machine cost companies?

A: Research industrial machinery manufacturers specializing in roll forming equipment. Top providers include global suppliers like BRUDERER and domestic specialists such as Samco Machinery and Formtek Group.Q: How do metal roofing machine cost manufacturers determine pricing?

A: Pricing reflects engineering complexity, material durability, and customization options. High-volume manufacturers often offer better economies of scale compared to boutique workshop producers.Q: Why do quotes from metal roofing machine cost company vary significantly?

A: Variations stem from differences in build quality, warranty coverage, energy efficiency ratings, and included features like automatic tool changers or IoT monitoring systems.Q: What's the typical price range for industrial-grade metal roofing machines?

A: Entry-level machines start around $50,000, while fully automated production lines can exceed $500,000. Mid-range systems with coil handling capabilities average $150,000-$300,000.-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025