Euro 1100 Metal Roof Tile Making Machine - High Efficiency & Quality

The Vanguard of Roofing: Understanding the Modern Metal Roof Tile Industry

The global roofing industry is undergoing a significant transformation, driven by demands for sustainability, durability, and aesthetic versatility. Metal roof tiles, in particular, have emerged as a dominant force, offering superior longevity, energy efficiency, and resistance to extreme weather conditions compared to traditional roofing materials. This surge in demand necessitates advanced manufacturing solutions capable of producing high-quality, precision-formed tiles at scale. Within this dynamic landscape, the Euro 1100 Metal roof tile making machine stands out as a pivotal innovation, addressing the intricate requirements of modern architectural design and construction.

Industry trends indicate a continuous shift towards pre-painted galvanized iron (PPGI) and Galvalume (Alu-Zinc) steel as primary raw materials for metal roofing, owing to their excellent corrosion resistance and lightweight properties. Automation in production lines is no longer a luxury but a necessity, enhancing output efficiency, reducing labor costs, and ensuring consistent product quality. Furthermore, the market demands machines that can adapt to various profiles and thicknesses, reflecting diverse regional architectural styles and structural requirements. The integration of Industry 4.0 principles, such as IoT connectivity and real-time data analytics, is also becoming increasingly vital for optimizing production processes and predictive maintenance.

This article delves into the capabilities and significance of the Euro 1100 Metal roof tile making machine, exploring its technical prowess, operational advantages, and strategic implications for businesses aiming to excel in the competitive metal roofing sector. We will dissect its core functionalities, application versatility, and the crucial factors that underscore its position as a leading manufacturing solution.

Unveiling the Euro 1100 Metal Roof Tile Making Machine: A Technical Deep Dive

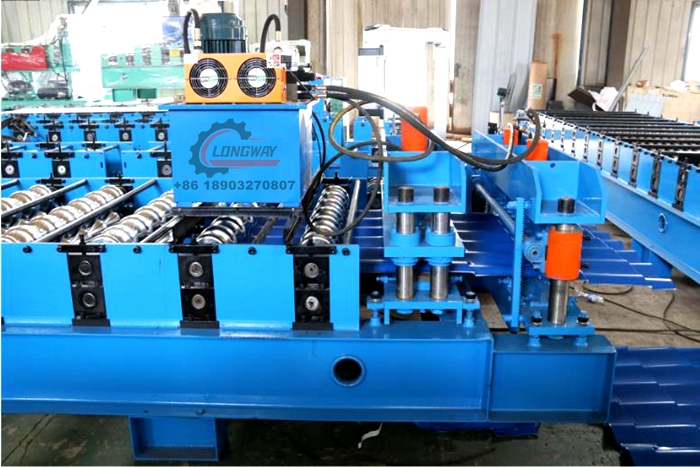

The Euro 1100 Metal roof tile making machine is an advanced roll forming system engineered for the precise and efficient production of high-quality metal roof tiles. It is specifically designed to handle a wide array of coil materials, including pre-painted galvanized steel, aluminum, and Galvalume, with varying thicknesses suitable for diverse applications. At its core, the machine leverages a sophisticated roll forming process, transforming flat metal coils into intricate tile profiles with consistent dimensions and superior finish.

Key components of this robust machine include an uncoiler, which feeds the raw material into the system; a precision guiding system ensuring accurate material alignment; a series of highly durable forming rollers, meticulously designed to shape the metal step-by-step; a hydraulic or pneumatic cutting device for precise tile length execution; and a control system, typically a Programmable Logic Controller (PLC) with an intuitive Human-Machine Interface (HMI), for seamless operation and monitoring. The forming rollers, often crafted from high-grade alloy steels like GCr15 or Cr12MoV, undergo meticulous heat treatment and hard chrome plating to enhance their wear resistance and extend their operational lifespan, ensuring consistent tile quality over millions of cycles.

The machine's design prioritizes stability and minimal deflection during high-speed operation, which is critical for maintaining tight tolerances on tile dimensions and profile integrity. Its robust frame, typically constructed from welded structural steel, is stress-relieved to prevent deformation over time, contributing to the machine's long-term accuracy and reliability. This meticulous engineering ensures that each tile produced by the Euro 1100 Metal roof tile making machine meets stringent quality benchmarks, vital for both structural integrity and aesthetic appeal.

The Precision Manufacturing Process: Crafting the Euro 1100 Machine

The integrity and performance of the Euro 1100 Metal roof tile making machine are rooted in a highly controlled and sophisticated manufacturing process of its own components. Unlike simple fabrication, producing a high-precision roll forming machine involves a complex interplay of material science, advanced machining, and rigorous quality control, ensuring the machine's longevity and the consistent quality of the tiles it produces.

Material Selection and Sourcing

The foundation of a reliable machine begins with material selection. For critical components like forming rollers, high-carbon, high-chromium tool steels (e.g., Cr12MoV, SKD11 equivalents) are chosen for their exceptional wear resistance and hardenability. Structural frames utilize high-strength, low-alloy (HSLA) steels to provide rigidity and absorb operational stresses. Bearings and electrical components are sourced from globally recognized suppliers, ensuring their reliability and interchangeability.

Advanced Manufacturing Processes of Components

- CNC Machining: Precision is paramount. Components such as forming rollers, shafts, and cutting dies undergo extensive CNC (Computer Numerical Control) machining. This ensures micron-level accuracy in dimensions and surface finishes, critical for smooth material flow and precise tile profiling. CNC milling, turning, and grinding operations are standard practice, minimizing human error and maximizing part consistency.

- Heat Treatment: To enhance the mechanical properties of wear-prone parts, specialized heat treatment processes are applied. For example, forming rollers are typically subjected to quenching and tempering (Q+T) to achieve a hardness of HRC 58-62, drastically improving their wear resistance. This process also optimizes the microstructure of the steel, preventing premature fatigue and deformation.

- Surface Treatment: Post-machining, critical surfaces like those of the forming rollers are often hard chrome plated or nitrided. Hard chrome plating provides a thin, extremely hard, and corrosion-resistant layer, further reducing friction and extending component lifespan. This also gives the machine a clean, industrial aesthetic.

- Welding and Fabrication: The main frame and structural elements are fabricated using high-quality steel plates, precisely cut and welded. Stress relieving through annealing or vibratory stress relief (VSR) is crucial after welding to remove internal stresses, preventing distortion and ensuring structural integrity over the machine's operational life.

Rigorous Inspection Standards

Every stage of the manufacturing process for the Euro 1100 Metal roof tile making machine is subjected to stringent quality control. This includes:

- Material Certification: Incoming raw materials are checked against supplier certifications to ensure they meet specified chemical composition and mechanical properties.

- Dimensional Inspection: Post-machining, components are measured using precision instruments (e.g., CMMs, micrometers, calipers) to verify adherence to design tolerances.

- Hardness Testing: Heat-treated parts undergo hardness testing (e.g., Rockwell hardness test) to confirm they meet the required hardness levels for wear resistance.

- Assembly and Alignment: During assembly, critical alignments (e.g., roller station alignment, shaft parallelism) are verified using laser alignment tools and precision gauges to ensure smooth and accurate roll forming.

- Functional Testing: The assembled machine undergoes extensive dry-run and wet-run (with material) testing to validate its operational parameters, including speed, accuracy, cutting performance, and tile profile consistency. This testing often adheres to international standards such as ISO 9001 quality management principles.

The typical service life of a well-maintained Euro 1100 Metal roof tile making machine is between 15 to 25 years, a testament to the quality of its components and manufacturing processes. These machines find application across various industries that utilize high-quality metal roofing, from large-scale industrial constructions (e.g., steel mills, petrochemical plants for their utility buildings) to residential developments and public infrastructure. The precise profiles created by the machine contribute to superior weather sealing, energy efficiency (due to thermal reflectivity of metal roofing), and corrosion resistance of the finished roof, making it ideal for demanding environments.

Core Technical Parameters & Specifications: Euro 1100 Metal Roof Tile Making Machine

Understanding the technical specifications of the Euro 1100 Metal roof tile making machine is crucial for assessing its suitability for specific production needs. These parameters dictate the machine's performance, capacity, and the range of materials it can effectively process. Below is a detailed table outlining typical specifications for a high-performance machine of this caliber.

These specifications underscore the Euro 1100 Metal roof tile making machine's capability to deliver high-volume, precision-engineered metal roof tiles, meeting the diverse demands of the construction sector. The emphasis on robust components and advanced control systems ensures minimal downtime and superior product quality, translating directly into enhanced profitability for manufacturers.

Applications & Market Impact: The Versatility of Metal Roof Tiles

The tiles produced by the Euro 1100 Metal roof tile making machine find extensive applications across a myriad of construction sectors, owing to their inherent advantages over traditional roofing materials. Their versatility makes them ideal for both new constructions and renovation projects, significantly impacting market dynamics by offering superior performance and aesthetic options.

Key Application Scenarios:

- Residential Buildings: From modern suburban homes to traditional dwellings, metal roof tiles offer homeowners long-term durability, reduced maintenance, and a wide palette of colors and profiles to enhance curb appeal. The lightweight nature of metal tiles also reduces structural load, making them suitable for various architectural designs.

- Commercial and Industrial Facilities: Warehouses, factories, shopping centers, and office complexes benefit immensely from metal roofing. The robust nature of metal tiles provides excellent protection against harsh industrial environments, fire, and heavy weather. Their energy-efficient properties (high solar reflectivity) can also lead to significant cooling cost reductions.

- Agricultural Structures: Barns, livestock shelters, and storage facilities require resilient roofing solutions that can withstand environmental stressors. Metal roof tiles, known for their resistance to mold, mildew, and pests, provide a hygienic and long-lasting cover.

- Public Infrastructure: Schools, hospitals, community centers, and transportation hubs demand roofing materials that offer public safety, longevity, and low lifecycle costs. Metal tiles fit these criteria, providing fire resistance and structural integrity.

- Specialized Projects: This includes coastal properties where salt corrosion is a concern (requiring specific coatings like PVDF), high-wind regions, and areas prone to heavy snowfall. The interlocking design and superior fastening capabilities of metal tiles, precisely formed by the Euro 1100 Metal roof tile making machine, ensure resilience in such challenging conditions.

Advantages of Metal Roof Tiles in Typical Applications:

- Energy Efficiency: Many metal roof tiles are ENERGY STAR® certified due to their high solar reflectance, which can significantly reduce cooling loads in hot climates. This translates to substantial energy savings for building owners.

- Superior Durability & Longevity: With proper installation, metal roofs can last 40-70 years, far exceeding traditional asphalt shingles (12-20 years). They resist cracking, shrinking, and erosion, making them highly cost-effective over their lifespan.

- Exceptional Anti-Corrosion Properties: Utilizing materials like Galvalume or high-quality pre-painted steel (PPGI) with advanced coatings ensures excellent resistance against rust and corrosion, even in harsh weather conditions or industrial atmospheres.

- Lightweight: Metal tiles are significantly lighter than concrete or clay tiles, reducing the structural demands on buildings and potentially lowering construction costs.

- Fire Resistance: Metal roofing is non-combustible and often carries a Class A fire rating, offering superior fire protection compared to other materials.

- Environmental Benefits: Metal roofs are typically made from a high percentage of recycled content and are 100% recyclable at the end of their long life, contributing to sustainable building practices.

The capability of the Euro 1100 Metal roof tile making machine to produce tiles that embody these advantages reinforces its market impact, enabling manufacturers to cater to the growing demand for sustainable, resilient, and aesthetically pleasing roofing solutions across diverse sectors.

Advanced Features & Technical Advantages of the Euro 1100 Series

The Euro 1100 Metal roof tile making machine distinguishes itself through a suite of advanced features and technical advantages that optimize production efficiency, material utilization, and product quality. These innovations are critical for manufacturers seeking to gain a competitive edge in a demanding market.

Precision Engineering for Superior Tile Profiles:

- Optimized Roller Design: The multi-stage roll forming process employs precisely engineered rollers that gradually shape the metal, minimizing stress and preventing material deformation or cracking, even with thicker gauges or complex profiles. This ensures uniform material thickness distribution and dimensional accuracy of the final tile.

- Advanced Hydraulic/Pneumatic Shearing: Equipped with a high-speed, post-forming cutting system, the machine ensures clean, burr-free cuts with minimal material waste. The flying shear mechanism allows for continuous production without stopping the main line, significantly boosting output.

Automation and Intelligent Control:

- Intuitive PLC & HMI: The Programmable Logic Controller (PLC) with a user-friendly Human-Machine Interface (HMI) enables operators to easily input tile length, quantity, and profile settings. It provides real-time feedback on production status, error diagnostics, and maintenance alerts, reducing reliance on highly skilled labor.

- Automated Length Measurement: High-precision encoders ensure accurate length measurement, allowing for precise control over tile dimensions, crucial for seamless installation and minimizing scrap.

- Variable Frequency Drive (VFD): Integrated VFDs control the speed of the main motor, allowing for smooth acceleration and deceleration, optimizing energy consumption, and adapting the production speed to various material types and thicknesses without sacrificing quality.

Material Versatility & Efficiency:

- Wide Material Compatibility: Beyond standard PPGI and Galvalume, the machine can be configured to process aluminum, copper, and even stainless steel, expanding the range of products a manufacturer can offer.

- Minimized Material Waste: The optimized design of the roll tooling and precise cutting system significantly reduces scrap material, contributing to lower production costs and environmental sustainability.

Robustness and Low Maintenance:

- Heavy-Duty Construction: The machine's solid steel frame, precisely machined components, and high-quality bearings ensure exceptional stability and vibration damping, even during intensive, continuous operation.

- Durable Components: Rollers made from high-grade, heat-treated steel with hard chrome plating offer superior wear resistance, reducing the frequency of tooling replacement and maintenance.

- Integrated Lubrication Systems: Automated lubrication points for critical bearings and moving parts ensure smooth operation and extend the life of mechanical components, minimizing manual intervention.

These technical advantages collectively position the Euro 1100 Metal roof tile making machine as a leader in its category, offering manufacturers unparalleled precision, efficiency, and reliability, essential for meeting the evolving demands of the global construction industry.

Selecting the Right Partner: Manufacturer Comparison & Considerations

Investing in a Euro 1100 Metal roof tile making machine is a significant decision requiring careful evaluation of potential manufacturers. While many suppliers exist, discerning the truly reliable partners from the rest hinges on a thorough assessment of their capabilities, historical performance, and commitment to customer success. Here are critical factors to consider when comparing manufacturers:

Key Comparison Metrics:

- Technological Expertise and R&D: A leading manufacturer will demonstrate a robust R&D department, continually innovating and integrating the latest technologies (e.g., IoT, AI for predictive maintenance) into their machines. Look for evidence of patented technologies or significant advancements in roll forming precision.

- Manufacturing Quality and Standards: Beyond basic specifications, inquire about their internal quality control protocols. Do they adhere to international standards like ISO 9001 for quality management? What are their material sourcing policies? Are critical components (e.g., bearings, motors, PLCs) sourced from reputable global brands?

- Customization Capabilities: The ability to tailor the Euro 1100 Metal roof tile making machine to specific profile designs, material gauges, or production volumes is a significant advantage. A flexible manufacturer can provide bespoke solutions that precisely match your market demands.

- After-Sales Service and Support: This is paramount. Evaluate their commitment to comprehensive technical support, spare parts availability, remote diagnostics, and on-site service. A manufacturer with a global service network and a quick response time minimizes downtime and protects your investment.

- Experience and Track Record: How many years has the manufacturer been in the industry? Can they provide references or case studies from similar projects? A long history of successful installations globally indicates reliability and expertise.

- Training Programs: Do they offer detailed training for your operators and maintenance staff? Proper training ensures efficient machine operation, prolongs machine life, and reduces operational errors.

- Warranty and Guarantees: Understand the warranty terms for the machine and its components. A strong warranty reflects the manufacturer's confidence in their product quality.

Illustrative Manufacturer Comparison (Hypothetical Data):

Choosing a manufacturer for your Euro 1100 Metal roof tile making machine should prioritize long-term value, reliability, and support over initial cost savings. A reputable manufacturer will not only provide a superior machine but also a partnership that ensures operational excellence and continuous improvement for your business.

Customization Solutions: Tailored for Your Success

The dynamic nature of the construction industry, coupled with varying regional architectural preferences, necessitates highly adaptable manufacturing equipment. The Euro 1100 Metal roof tile making machine offers extensive customization options, allowing businesses to precisely tailor their production capabilities to specific market demands and unique project requirements. This flexibility is a significant advantage, ensuring the machine remains a valuable asset for years to come.

Key Areas of Customization:

- Profile Design & Tooling: The most common customization is for specific tile profiles. Whether it's a unique architectural style (e.g., Roman tile, classic tile, or new wave profiles), a reputable manufacturer can design and manufacture bespoke roll tooling sets to produce virtually any desired profile. This allows companies to differentiate their product offerings.

- Material Gauge and Type Adaptation: While the standard Euro 1100 Metal roof tile making machine handles common gauges, it can be engineered to process thinner or thicker materials (e.g., 0.25mm to 1.0mm) or specialized alloys beyond PPGI/Galvalume, such as copper or specific grades of stainless steel, by adjusting roller materials, frame rigidity, and motor power.

- Production Speed and Automation Levels: For high-volume operations, the machine can be upgraded with higher-speed motors, advanced control systems, and automated stacking/packaging solutions to achieve production rates exceeding standard specifications. Conversely, for smaller operations, a more manual setup might be preferred for cost efficiency.

- Integration with Auxiliary Equipment: The Euro 1100 Metal roof tile making machine can be integrated with various auxiliary equipment to form a complete production line. This includes automatic decoilers with higher load capacities, straightening devices, embossing units for texture, punching units for pre-drilled holes, automated stackers, and shrink-wrapping or bundling machines for efficient material handling and packaging.

- Control System Customization: While standard PLCs offer robust functionality, clients may request specific brand PLCs (e.g., Siemens, Allen-Bradley) to match existing factory standards or specialized software functionalities for enhanced data logging, remote monitoring, or integration with Enterprise Resource Planning (ERP) systems.

- Safety Features and Compliance: Customization can extend to incorporating region-specific safety standards (e.g., OSHA, CE marking requirements) by adding specific guarding, emergency stop protocols, and interlocks, ensuring the machine meets all local industrial safety regulations.

- Environmental Adaptations: For operations in extreme climates, options like reinforced components for harsh weather, specialized lubrication systems for low temperatures, or enhanced dust protection for abrasive environments can be integrated.

Engaging with a manufacturer that possesses deep engineering expertise and a flexible design philosophy is crucial for successful customization. This collaborative approach ensures that the adapted Euro 1100 Metal roof tile making machine not only meets current production needs but also offers scalability and adaptability for future market shifts, maximizing return on investment.

Real-World Impact: Application Case Studies

The true value of the Euro 1100 Metal roof tile making machine is best demonstrated through its successful deployment in real-world scenarios. These hypothetical case studies illustrate how businesses have leveraged the machine's capabilities to achieve significant operational efficiencies, expand product lines, and enhance profitability.

Case Study 1: Large-Scale Residential Development in a Coastal Region

Client: "Ocean Vista Developments," a leading property developer specializing in high-end residential communities in coastal areas of the Mediterranean.

Challenge: Ocean Vista required a durable, aesthetic, and corrosion-resistant roofing solution for 500 new villas. Traditional clay tiles were heavy and prone to breakage, while asphalt shingles offered insufficient longevity against salt spray and strong winds. Importing custom metal tiles was proving cost-prohibitive and logistics-intensive.

Solution: They invested in a customized Euro 1100 Metal roof tile making machine, configured to produce a specific "Mediterranean Wave" profile from 0.5mm Galvalume steel with a PVDF coating for enhanced corrosion protection. The machine's precise hydraulic cutting system ensured minimal waste and perfect tile alignment, crucial for the complex roof designs.

Outcome: By producing tiles in-house, Ocean Vista reduced roofing costs by 30% and significantly accelerated project timelines. The superior anti-corrosion properties and lightweight nature of the custom metal tiles (produced at an average rate of 12 meters/minute) resulted in a projected roof lifespan of 50+ years, offering a compelling selling point to homeowners and reinforcing the developer's reputation for quality. The machine's robust build ensured continuous operation even in demanding outdoor conditions during installation phases.

Case Study 2: Expansion of an Industrial Roofing Supplier in Southeast Asia

Client: "Apex Steel Solutions," a regional supplier of industrial building materials, looking to diversify into corrugated metal roof tiles for factories and warehouses.

Challenge: Apex needed to produce high volumes of corrugated and standing seam profiles for the rapidly expanding industrial sector. Existing equipment was old, slow, and lacked the precision for modern architectural demands. They also faced challenges with material thickness variations from local suppliers.

Solution: Apex acquired a high-speed Euro 1100 Metal roof tile making machine with an advanced PLC control system and an integrated automatic uncoiler capable of handling 10-ton coils. The machine was equipped with quick-change tooling to switch between corrugated and standing seam profiles rapidly. Its VFD-controlled speed and precise roll-forming mechanism handled material thickness variations from 0.4mm to 0.7mm seamlessly.

Outcome: Apex Steel Solutions increased their production capacity by over 200%, meeting urgent demands for several large factory projects. The efficiency and consistency of the Euro 1100 Metal roof tile making machine led to a 15% reduction in scrap material and significantly improved product quality. This allowed them to secure major contracts, previously out of reach, due to their enhanced ability to deliver large quantities of high-precision metal roofing on tight schedules.

Case Study 3: Small-to-Medium Enterprise (SME) Targeting Niche Markets

Client: "Heritage Roofing Co.," an SME focused on providing custom metal roofing solutions for historical renovations and unique architectural projects.

Challenge: Heritage Roofing often required short runs of very specific, historically accurate or custom-designed metal tile profiles, often from specialized materials like copper or aged zinc. Outsourcing was slow, expensive, and lacked quality control.

Solution: Heritage invested in a compact, highly precise Euro 1100 Metal roof tile making machine, specifically customized with easily interchangeable roller sets for rapid profile changes. The control system was configured for efficient short-run production, minimizing setup times. They also opted for rollers made from specialized tool steel to handle softer metals like copper without marring or deforming the surface.

Outcome: The ability to produce niche profiles in-house transformed Heritage Roofing Co. into a bespoke solutions provider. They could now offer faster turnaround times and tighter quality control for their specialized projects. This led to a significant increase in client base for high-value, custom projects, boosting their profit margins and market reputation within their specialized segment. The precision of the machine ensured that even historically complex profiles were replicated perfectly, maintaining the integrity of restoration efforts.

Ensuring Trust and Reliability: Quality Assurance & Support

For B2B decision-makers, the purchase of capital equipment like the Euro 1100 Metal roof tile making machine is a strategic investment that hinges on trust and long-term reliability. A reputable manufacturer doesn't just sell a machine; they offer a comprehensive ecosystem of quality assurance, certifications, and robust customer support to safeguard that investment and ensure operational continuity.

Authoritativeness through Certifications and Industry Presence:

- ISO 9001 Certification: This internationally recognized standard for quality management systems is a fundamental indicator of a manufacturer's commitment to consistent quality, continuous improvement, and customer satisfaction. It ensures that every step from design to delivery is systematically controlled.

- CE Marking: For machines destined for the European market, CE marking signifies conformity with European health, safety, and environmental protection standards. It assures buyers that the equipment meets stringent safety requirements.

- Rigorous Testing and Validation: Before shipment, every Euro 1100 Metal roof tile making machine undergoes extensive factory acceptance testing (FAT). This includes prolonged operational runs under various load conditions, precision checks on tile dimensions and cut lengths, and comprehensive electrical and safety system verification. Test reports and performance data are often provided to the client.

- R&D and Innovation Leadership: A manufacturer that actively invests in R&D demonstrates a commitment to staying at the forefront of technology, ensuring their machines incorporate the latest advancements in efficiency, automation, and material processing. Partnerships with academic institutions or industry bodies further bolster their authoritative standing.

- Global Partnerships and Track Record: Collaborations with leading component suppliers (e.g., Siemens, Bosch Rexroth, Schneider Electric) for electrical and hydraulic systems, along with a documented history of successful installations worldwide, serve as strong testimonials to a manufacturer's reliability and global reach.

Trustworthiness in Service and Support:

- Comprehensive Warranty: A standard warranty for a Euro 1100 Metal roof tile making machine typically covers 12 to 24 months for mechanical and electrical components, excluding wear parts. Leading manufacturers often offer extended warranty options, reflecting their confidence in product durability.

- Transparent Delivery Cycle: The typical delivery cycle for a standard Euro 1100 Metal roof tile making machine ranges from 45 to 75 working days, depending on customization levels and current production schedules. A reliable manufacturer provides clear timelines and regular updates throughout the manufacturing and shipping process, ensuring transparency and predictability for your project planning.

- Robust After-Sales Support: This includes:

- Remote Technical Assistance: Availability of hotline support, email, and video conferencing for immediate troubleshooting. Many modern machines can also be equipped for remote diagnostics.

- On-site Installation and Training: Experienced engineers can be dispatched for machine installation, commissioning, and comprehensive training for your operators and maintenance teams, ensuring they are proficient in operation, routine maintenance, and basic troubleshooting.

- Spare Parts Availability: A commitment to maintaining an adequate stock of critical spare parts, with efficient logistics for rapid worldwide delivery, minimizes potential downtime.

- Maintenance Programs: Offering scheduled maintenance visits or preventative maintenance guides helps prolong the machine's lifespan and ensure peak performance.

- Customer Feedback Integration: Reputable manufacturers actively solicit and integrate customer feedback into their product development and service improvement cycles, demonstrating a true partnership approach.

By prioritizing manufacturers who excel in these areas, businesses can mitigate risks, ensure operational efficiency, and build a lasting, profitable relationship grounded in mutual trust and shared success, making the investment in a Euro 1100 Metal roof tile making machine a truly confident one.

Frequently Asked Questions (FAQ) about the Euro 1100 Metal Roof Tile Making Machine

Q1: What types of materials can the Euro 1100 Metal roof tile making machine process?

A1: The machine is primarily designed to process pre-painted galvanized iron (PPGI), Galvalume (Alu-Zinc) steel, and aluminum coils. Depending on customization, it can also handle stainless steel or copper within specified thickness ranges (typically 0.3mm to 0.8mm).

Q2: What is the typical production speed of this machine?

A2: The standard production speed for the Euro 1100 Metal roof tile making machine ranges from 8 to 15 meters per minute. This speed can vary based on the complexity of the tile profile, material thickness, and the specific automation level of the machine. Higher speeds can be achieved with advanced configurations.

Q3: How precise is the length cutting for the tiles?

A3: The machine features a high-precision hydraulic cutting system with an encoder for accurate length measurement. It typically achieves a cutting tolerance of ±1mm for tile lengths up to 10 meters, ensuring consistent product dimensions for easy installation.

Q4: What kind of maintenance does the Euro 1100 Metal roof tile making machine require?

A4: Routine maintenance includes daily checks of hydraulic oil levels and pressure, regular lubrication of moving parts (bearings, chains), inspection of rollers for wear, and cleaning of electrical components. Annual professional servicing is recommended to check alignment, electrical systems, and conduct comprehensive wear inspections, extending the machine's long service life.

Q5: Can the machine produce different tile profiles?

A5: Yes, the Euro 1100 Metal roof tile making machine is highly customizable. It can produce various tile profiles by changing the roll tooling sets. Manufacturers often provide multiple tooling sets or can design custom profiles based on client specifications, making it versatile for different market demands.

Q6: What is the typical delivery and installation process?

A6: After order confirmation and down payment, manufacturing typically takes 45-75 working days. Once completed and tested (FAT), the machine is prepared for shipment. Reputable manufacturers offer on-site installation and commissioning services, sending experienced engineers to your facility to set up the machine, perform final calibrations, and train your operating and maintenance staff.

Q7: What kind of warranty and after-sales support is provided?

A7: Standard warranties usually range from 1 to 2 years for the main machine components. After-sales support includes remote technical assistance (phone, email, video), availability of spare parts, and options for on-site support. Many manufacturers provide lifetime technical support for their machinery, ensuring long-term operational peace of mind.

Conclusion: Paving the Future of Metal Roofing

The construction industry's accelerating demand for durable, efficient, and aesthetically pleasing roofing solutions positions metal roof tiles at the forefront of modern building practices. The Euro 1100 Metal roof tile making machine represents a critical technological advancement in this sector, offering unparalleled precision, automation, and versatility for manufacturers. Its robust construction, intelligent control systems, and ability to handle diverse materials and profiles ensure that it meets the rigorous demands of high-volume production while maintaining the highest quality standards.

Investing in a sophisticated machine like the Euro 1100 Metal roof tile making machine is more than just acquiring equipment; it is a strategic decision to enhance competitiveness, expand market reach, and ensure long-term profitability. Its capacity to deliver superior products, coupled with comprehensive support from a reliable manufacturer, empowers businesses to navigate evolving market trends and capitalize on the growing global demand for high-performance metal roofing solutions. As urbanization continues and environmental consciousness rises, machines like the Euro 1100 will be instrumental in shaping sustainable and resilient urban landscapes, one precisely formed tile at a time.

References

- Metal Roofing Alliance. "Benefits of Metal Roofing." Metal Roofing Alliance White Papers, 2023.

- Roll Forming Magazine. "Advances in Roll Forming Technology for Construction Applications." Industry Insights, Vol. 25, No. 3, 2022.

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements. ISO Standards Publication, 2015.

- The Metal Construction Association. "Sustainable Attributes of Metal Roofing." Technical Bulletins, 2021.

- European Committee for Standardization (CEN). Machinery Directive 2006/42/EC (CE Marking). Official Journal of the European Union, 2006.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025