Revolutionizing Metal Roofing: Software Enhancements for Rolling Machines

The evolution of metal roof rolling machines has been dramatically accelerated by the integration of advanced software systems. From reducing errors to increasing production speeds, software solutions are reshaping the way these machines operate. Let’s explore how software can enhance the operation and efficiency of sheet metal roofing machines for sale, metal roof tile making machines, and other advanced systems, while also addressing the overall metal roofing machine cost.

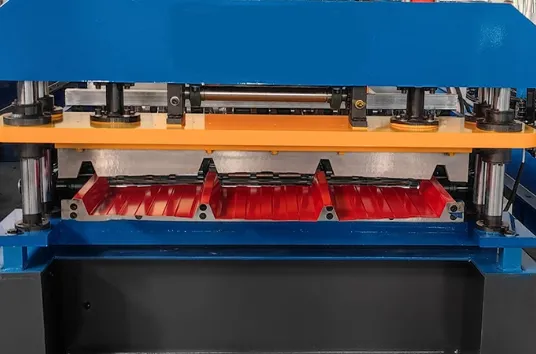

Metal Roof Rolling Machines:Precision Made Simple with Software Integration

One of the most significant advantages of integrating software with metal roof rolling machines is the ability to achieve precise results effortlessly.

-

Accurate Measurements: Advanced software calculates dimensions and material usage to exact specifications, eliminating manual errors.

-

Consistent Profiles: Automated controls ensure uniformity across all roof panels, meeting the highest quality standards.

-

Customizable Designs: Software allows for the creation of various patterns and profiles, making metal roof tile making machinesversatile for different projects.

This level of precision minimizes waste and maximizes output, making software a cost-effective addition.

Metal Roof Rolling Machines:Boosting Production Efficiency with Automation

Software-driven automation is transforming the efficiency of sheet metal roofing machines for sale:

-

Optimized Workflow: Integrated software sequences the production process, ensuring smooth and uninterrupted operations.

-

Higher Speeds: Automated settings enable machines to operate at maximum speed without compromising accuracy.

-

Energy Management: Advanced software optimizes energy consumption, reducing operational costs.

This boost in efficiency reduces the metal roofing machine cost per project, making it a smart investment for contractors.

Metal Roof Rolling Machines:Real-Time Monitoring and Diagnostics

Modern software solutions offer real-time insights into the performance of metal roof rolling machines:

-

Performance Tracking: Operators can monitor production metrics, such as output rates and material usage, in real-time.

-

Error Detection: Automated diagnostics identify potential issues early, preventing costly downtime.

-

Remote Accessibility: Cloud-connected systems allow operators to manage machines from any location.

These features streamline operations, ensuring that machines run smoothly and efficiently at all times.

Software makes customization more accessible and affordable for metal roof tile making machines:

-

Design Flexibility: Operators can switch between designs quickly without requiring extensive reconfiguration.

-

Material Optimization: Software calculates the best way to use materials, reducing waste.

- Scalable Solutions: Whether for small projects or large-scale operations, software adjusts machine settings to match production needs.

By lowering material waste and enhancing adaptability, software significantly reduces the overall metal roofing machine cost.

The integration of software into sheet metal roofing machines for sale and related equipment is not just a trend—it’s a necessity. These advancements elevate precision, efficiency, and customization, ultimately delivering high-quality results while reducing costs.

Ready to take your roofing projects to the next level? Explore our range of advanced metal roof rolling machines today. Visit our website to discover cutting-edge solutions tailored to your needs!

-

Corrugated iron roofing sheet making machine with CE, AutoNoticiasNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNoticiasNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNoticiasNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNoticiasNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNoticiasNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNoticiasNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENoticiasNov.11, 2025