Feb . 18, 2025 08:37

Back to list

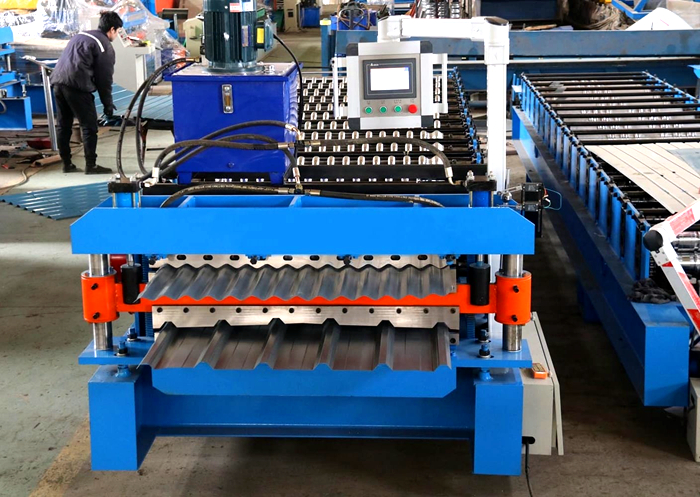

iron sheet roll forming machine

The world of construction and manufacturing is constantly evolving, with businesses and entrepreneurs steadily seeking ways to enhance efficiency and output. One of the pivotal innovations in this sector is the iron sheet roll forming machine, a tool that embodies technical precision and operational excellence. This machine has transformed the way metal roofing and wall panels are produced, offering both practicality and adaptability to various industrial needs.

The authority of a top-tier iron sheet roll forming machine manufacturer cannot be understated. Leading manufacturers not only provide machines but also offer extensive support in terms of training, maintenance, and software updates. Their reputation is built on years of delivering reliable machinery that meets international standards, ensuring trust and reliability for businesses investing in such technologies. Their endorsements and certifications further validate the machines' credibility, making them a trustworthy investment for companies looking to scale their metalworking capabilities. Building trustworthiness among clients and within the industry is perhaps the most significant aspect of the roll forming machine’s value proposition. Manufacturers often offer warranties and post-purchase support, emphasizing their commitment to product excellence and customer satisfaction. Moreover, each machine’s performance is backed by rigorous testing and quality assurance protocols, ensuring that customers receive only the best. In terms of product-specific advantages, iron sheet roll forming machines offer remarkable versatility. They can produce a wide array of profiles, each designed to meet specific structural and aesthetic requirements. This adaptability allows businesses to cater to diverse market demands swiftly. Additionally, the quality of the finished product is superior in terms of structural strength and surface finish, making these machines a worthy investment for quality-oriented enterprises. In essence, the iron sheet roll forming machine is more than just a piece of equipment; it is an embodiment of engineering prowess, industrial elegance, and economic utility. Its ability to streamline processes, reduce costs, and improve product consistency makes it a keystone in modern manufacturing. For businesses focused on growth and quality, investing in these machines aligns with both current and future production goals, illustrating forward-thinking and strategic planning. As industries continue to evolve, so too will the technologies that drive them, with the iron sheet roll forming machine leading in both innovation and application.

The authority of a top-tier iron sheet roll forming machine manufacturer cannot be understated. Leading manufacturers not only provide machines but also offer extensive support in terms of training, maintenance, and software updates. Their reputation is built on years of delivering reliable machinery that meets international standards, ensuring trust and reliability for businesses investing in such technologies. Their endorsements and certifications further validate the machines' credibility, making them a trustworthy investment for companies looking to scale their metalworking capabilities. Building trustworthiness among clients and within the industry is perhaps the most significant aspect of the roll forming machine’s value proposition. Manufacturers often offer warranties and post-purchase support, emphasizing their commitment to product excellence and customer satisfaction. Moreover, each machine’s performance is backed by rigorous testing and quality assurance protocols, ensuring that customers receive only the best. In terms of product-specific advantages, iron sheet roll forming machines offer remarkable versatility. They can produce a wide array of profiles, each designed to meet specific structural and aesthetic requirements. This adaptability allows businesses to cater to diverse market demands swiftly. Additionally, the quality of the finished product is superior in terms of structural strength and surface finish, making these machines a worthy investment for quality-oriented enterprises. In essence, the iron sheet roll forming machine is more than just a piece of equipment; it is an embodiment of engineering prowess, industrial elegance, and economic utility. Its ability to streamline processes, reduce costs, and improve product consistency makes it a keystone in modern manufacturing. For businesses focused on growth and quality, investing in these machines aligns with both current and future production goals, illustrating forward-thinking and strategic planning. As industries continue to evolve, so too will the technologies that drive them, with the iron sheet roll forming machine leading in both innovation and application.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products