How C Purlin Machines Improve Efficiency in Steel Structure Fabrication

In the world of steel structure fabrication, efficiency is paramount. The production of C purlins, essential structural components used in the construction of steel buildings, relies heavily on the performance of specialized machinery. C purlin machines, designed for continuous roll-forming of C-shaped steel profiles, are revolutionizing the way steel structures are fabricated. These machines not only enhance production speed but also improve precision, reduce labor costs, and minimize material wastage. This article will explore how C purlin machines are improving efficiency in steel structure fabrication.

Streamlined Production Process About C Purlin Machines

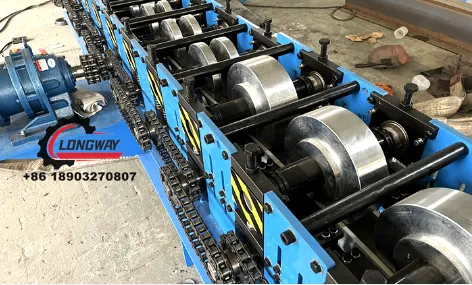

The core benefit of c purlin roll former lies in their ability to streamline the production process. Traditionally, producing steel purlins was a labor-intensive operation that required multiple steps and specialized equipment. C purlin machines, however, simplify this process into one continuous roll-forming system. The machine is fed with steel coils, which are passed through a series of rollers that progressively shape the material into the desired C-profile. This method is highly efficient, as it minimizes the need for manual intervention and speeds up the production cycle.

In addition to simplifying the process, modern c purlin roll forming machine can handle large volumes of material with minimal downtime. The machines are capable of running for extended periods without requiring frequent stops for adjustments, resulting in significantly faster production times. The continuous nature of the roll-forming process means that multiple purlins can be produced simultaneously, further increasing throughput. This increased production speed directly contributes to improved efficiency in the fabrication process.

Precision and Consistency in Manufacturing About C Purlin Machines

Another key advantage of C purlin machines is their ability to produce highly precise and consistent purlins. In traditional fabrication methods, human error and machine calibration issues often led to variations in the dimensions of the purlins, resulting in waste and rework. C purlin machines, however, are equipped with advanced digital control systems that ensure the production of purlins with exact specifications. These systems enable manufacturers to set precise parameters for the thickness, width, and length of the purlins, ensuring that every piece produced meets the required standards.

The precision of C purlin machines reduces the need for secondary operations such as cutting or welding, which are often required when dimensional inconsistencies arise in traditional methods. This not only saves time but also minimizes the waste of raw materials, leading to cost savings and a more sustainable fabrication process. Consistency in manufacturing also ensures that the purlins fit perfectly into the structural framework of the building, reducing installation time and labor costs.

Automation and Labor Cost Reduction About C Purlin Machines

One of the most significant benefits of C purlin machines is their automation capabilities. Modern C purlin machines are equipped with automated features that significantly reduce the need for manual labor. Once the machine is set up, the entire production process can be handled with minimal operator intervention. This reduces the dependency on skilled labor and allows workers to focus on other tasks within the fabrication facility.

The automation of the production process also reduces the chances of human error, improving overall production quality. Operators can input the required specifications, and the machine will automatically adjust to produce the desired purlin dimensions. This eliminates the risk of incorrect measurements or misaligned profiles, ensuring that each purlin is consistent with the project’s requirements. The reduction in labor costs, combined with increased productivity, results in a higher return on investment for manufacturers.

Flexible Production for Customization About C Purlin Machines

C purlin machines are highly adaptable, offering the flexibility to produce purlins of various sizes, thicknesses, and profiles. This versatility allows manufacturers to meet the specific needs of different projects, whether it’s a large-scale industrial building, a warehouse, or a residential structure. The ability to adjust the machine settings to produce customized purlins without significant downtime enhances operational efficiency.

Additionally, many C purlin machines are equipped with punching and cutting capabilities, which further enhance their flexibility. These machines can create holes in the purlins for easy attachment of fasteners or bolts, which simplifies the assembly process on-site. The ability to produce customized purlins directly on the production line eliminates the need for additional equipment and reduces lead times, making the entire fabrication process more efficient.

Reduced Material Waste and Cost Savings With C Purlin Machines

The efficiency of C purlin machines extends beyond production speed and labor savings. One of the most significant improvements they offer is the reduction of material waste. In traditional fabrication methods, there is often excess material left over after cutting and shaping, leading to higher material costs. C purlin machines, on the other hand, operate with a high degree of material utilization.

The continuous roll-forming process minimizes scrap by ensuring that the material is used efficiently. The ability to adjust the machine to specific dimensions also reduces the risk of overproduction, further minimizing waste. This reduction in scrap material leads to cost savings for manufacturers, as less raw material is wasted during the production process. Additionally, some machines are equipped with advanced features that allow for precise material feeding, further optimizing the use of steel coils and reducing excess waste.

-

Corrugated iron roofing sheet making machine with CE, AutoNoticiasNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNoticiasNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNoticiasNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNoticiasNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNoticiasNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNoticiasNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENoticiasNov.11, 2025