velj . 16, 2025 04:21

Back to list

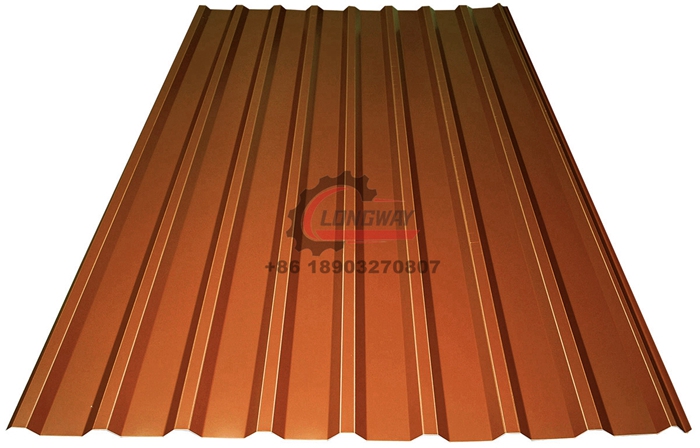

corrugated sheets roll forming machine

Corrugated sheets roll forming machines have become an indispensable component within the construction and manufacturing industries due to their efficiency and precision. These machines play a crucial role in the production of corrugated sheets, which are extensively used for roofing, cladding, and partitioning, providing durability and aesthetic appeal.

When considering expertise and authoritativeness, it’s crucial to acknowledge how manufacturers have integrated feedback mechanisms to assess the performance of each machine component in real time. Through such mechanisms, maintenance can be preemptive rather than reactive, a feature that significantly reduces downtime and prolongs the machine’s lifespan. Furthermore, continuous dialogues with industry experts ensure that these machines remain at the forefront of technological innovation, adapting to new materials and the evolving needs of the construction industry. Cost-effectiveness and return on investment are also pivotal when discussing the advantages of these machines. While the initial outlay may be significant, the enhancement in production capability, reduction in material waste, and labor efficiency assure a rapid payback period. This economic viability is further complemented by the machine's capacity to produce large volumes in short cycles, catering to both small and large-scale industrial demands. The trustworthiness of a corrugated sheets roll forming machine is fundamentally rooted in its compliance with industry standards and certifications, which serve as a quality assurance guarantee to purchasers. Manufacturers committed to ethical construction practices invest significantly in research and development to optimize these machines not only for performance and durability but also for environmental sustainability by minimizing energy consumption and ensuring material recyclability. In conclusion, the corrugated sheets roll forming machine epitomizes the harmonious integration of engineering proficiency and practical application, ensuring it remains a cornerstone in the construction and manufacturing landscape. Those looking to invest in such machinery are advised to partner with reputed manufacturers who can provide comprehensive support, from installation to after-sales service, ensuring every aspect of the machine is utilized to its full potential.

When considering expertise and authoritativeness, it’s crucial to acknowledge how manufacturers have integrated feedback mechanisms to assess the performance of each machine component in real time. Through such mechanisms, maintenance can be preemptive rather than reactive, a feature that significantly reduces downtime and prolongs the machine’s lifespan. Furthermore, continuous dialogues with industry experts ensure that these machines remain at the forefront of technological innovation, adapting to new materials and the evolving needs of the construction industry. Cost-effectiveness and return on investment are also pivotal when discussing the advantages of these machines. While the initial outlay may be significant, the enhancement in production capability, reduction in material waste, and labor efficiency assure a rapid payback period. This economic viability is further complemented by the machine's capacity to produce large volumes in short cycles, catering to both small and large-scale industrial demands. The trustworthiness of a corrugated sheets roll forming machine is fundamentally rooted in its compliance with industry standards and certifications, which serve as a quality assurance guarantee to purchasers. Manufacturers committed to ethical construction practices invest significantly in research and development to optimize these machines not only for performance and durability but also for environmental sustainability by minimizing energy consumption and ensuring material recyclability. In conclusion, the corrugated sheets roll forming machine epitomizes the harmonious integration of engineering proficiency and practical application, ensuring it remains a cornerstone in the construction and manufacturing landscape. Those looking to invest in such machinery are advised to partner with reputed manufacturers who can provide comprehensive support, from installation to after-sales service, ensuring every aspect of the machine is utilized to its full potential.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products