velj . 16, 2025 02:55

Back to list

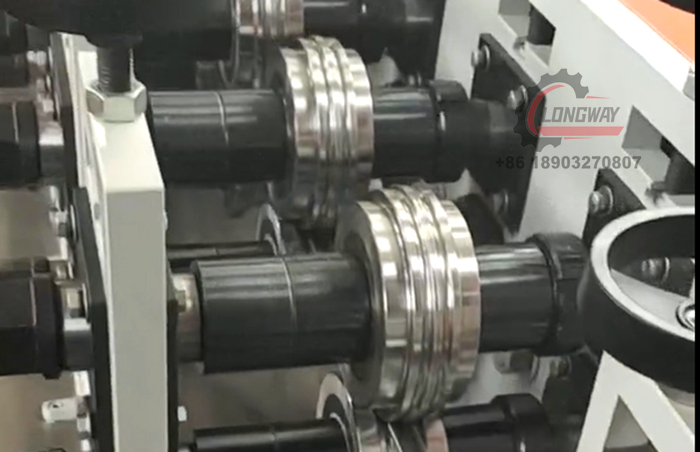

corrugated roof roll forming machine factory

In the rapidly evolving landscape of industrial manufacturing, the demand for high-quality, reliable machinery is more prominent than ever. Among these machines, the corrugated roof roll forming machine stands out due to its vital role in the production of durable and aesthetically pleasing roofing solutions. For businesses involved in the construction industry, sourcing this equipment from a credible and specialized factory is crucial. Here, let us explore why selecting the right factory makes all the difference and what key elements should be considered.

Trustworthiness is another vital aspect, especially when considerable financial investments are involved. An exemplary corrugated roof roll forming machine factory will offer transparent, comprehensive service pre- and post-sale, ensuring customers receive full value for their investments. This includes providing detailed machine specifications, honest pricing without hidden fees, and robust after-sales support. Factories that prioritize long-term relationships over short-term gains tend to offer extensive warranties, readily available spare parts, and dedicated customer service teams prepared to address any technical issues or queries. For any construction company looking to invest in a corrugated roof roll forming machine, conducting thorough research on the factory's reputation and capabilities is imperative. Consider factories that not only engineer superior machines but also contribute to industry innovations. These factories often engage in research and development to stay ahead of emerging trends and potential shifts in market demands, thereby ensuring their clients are always equipped with cutting-edge technology. Additionally, visiting the factory site can provide valuable insights into the manufacturing process and quality control measures. Engaging directly with the factory's engineers and witnessing the machinery in action allows potential buyers to evaluate machine performance and manufacturing standards firsthand. A factory that offers detailed walkthroughs and live demonstrations demonstrates confidence in its processes and equipment. In summary, the significance of selecting a reputable corrugated roof roll forming machine factory cannot be underestimated. Such a choice impacts not only the immediate quality and efficiency of production but also the long-term viability and success of roofing projects. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can ensure they partner with a factory that aligns with their needs and standards, ultimately leading to superior end products and enhanced competitive advantage in the construction sector.

Trustworthiness is another vital aspect, especially when considerable financial investments are involved. An exemplary corrugated roof roll forming machine factory will offer transparent, comprehensive service pre- and post-sale, ensuring customers receive full value for their investments. This includes providing detailed machine specifications, honest pricing without hidden fees, and robust after-sales support. Factories that prioritize long-term relationships over short-term gains tend to offer extensive warranties, readily available spare parts, and dedicated customer service teams prepared to address any technical issues or queries. For any construction company looking to invest in a corrugated roof roll forming machine, conducting thorough research on the factory's reputation and capabilities is imperative. Consider factories that not only engineer superior machines but also contribute to industry innovations. These factories often engage in research and development to stay ahead of emerging trends and potential shifts in market demands, thereby ensuring their clients are always equipped with cutting-edge technology. Additionally, visiting the factory site can provide valuable insights into the manufacturing process and quality control measures. Engaging directly with the factory's engineers and witnessing the machinery in action allows potential buyers to evaluate machine performance and manufacturing standards firsthand. A factory that offers detailed walkthroughs and live demonstrations demonstrates confidence in its processes and equipment. In summary, the significance of selecting a reputable corrugated roof roll forming machine factory cannot be underestimated. Such a choice impacts not only the immediate quality and efficiency of production but also the long-term viability and success of roofing projects. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can ensure they partner with a factory that aligns with their needs and standards, ultimately leading to superior end products and enhanced competitive advantage in the construction sector.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products