sij . 14, 2025 13:49

Back to list

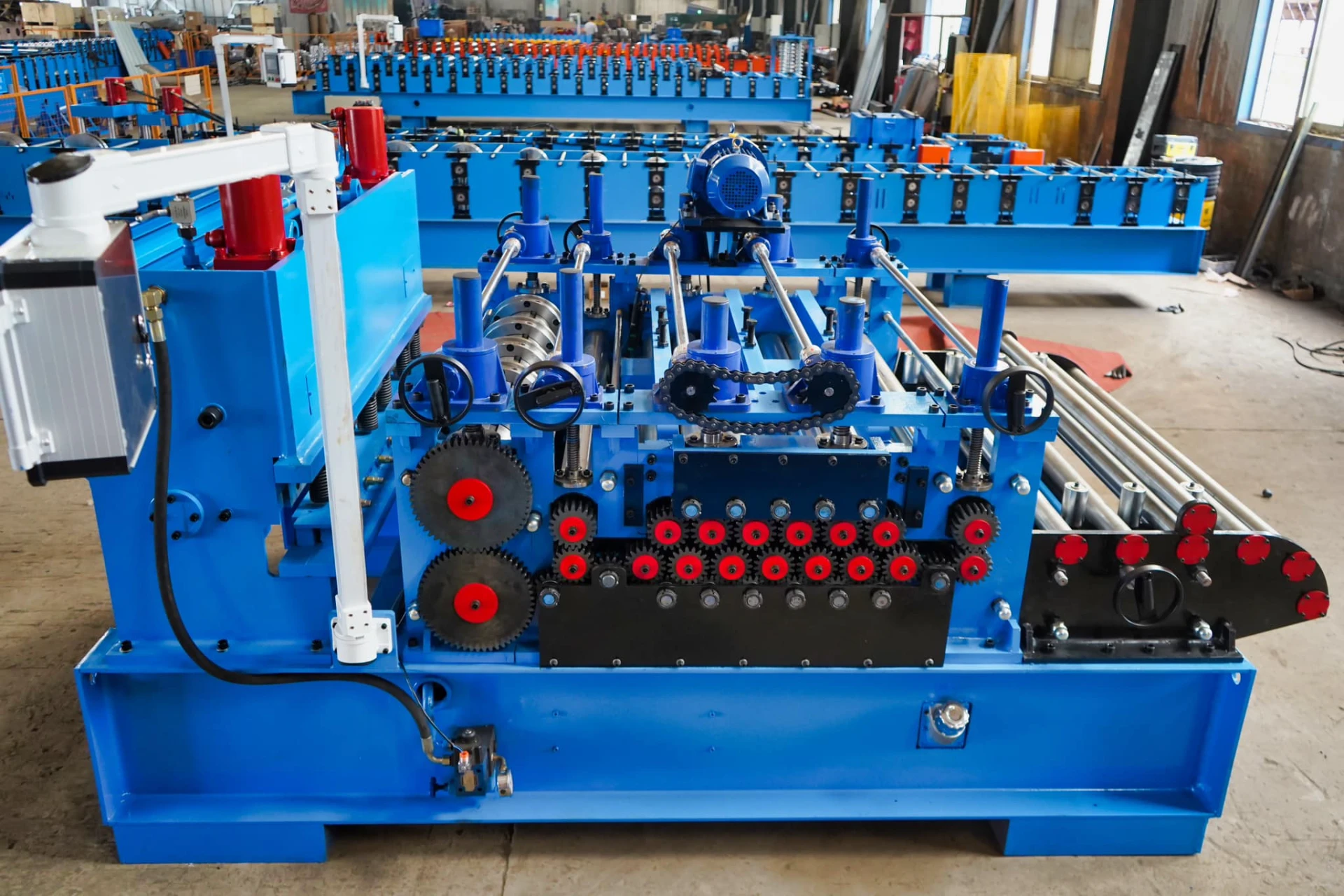

cladding roll forming machine

The world of manufacturing has experienced significant advancements, making the production of building materials more efficient and cost-effective. A prime example within the industry is the downpipe forming machine, a specialized piece of machinery designed to streamline the production of downpipes, crucial components in rainwater management systems. Employing a machine of this caliber not only enhances the quality and consistency of the products but also reflects the burgeoning reliance on technology-driven solutions in modern manufacturing.

Beyond technical specifications, real-world applications underscore the machine’s pivotal role in elevating business operations. Case studies reveal remarkable transformations in output quality and business scalability among businesses that have integrated downpipe forming machinery into their assembly lines. These success stories do not just highlight operational improvements; they underscore the machine's evolution from a mere tool to a cornerstone of strategic growth and innovation. In a sector characterized by stringent performance and durability demands, industry experts consistently advocate investing in technologically advanced and trustworthy equipment like the downpipe forming machine. The return on investment is not solely measured by immediate financial gains but also by the enhancement of product reliability and market reputation over time. As the construction landscape continues to evolve with an increasing emphasis on water conservation and sustainable practices, the integration of sophisticated machinery becomes an imperative. Conclusively, the downpipe forming machine represents more than a manufacturing instrument; it is a catalyst for efficiency, reliability, and innovation. Its integration within production systems not only meets but anticipates market needs, underscoring the imperative for businesses to adapt to the transforming industrial paradigm. As technological prowess and environmental responsibility become inextricably linked in consumer consciousness, the role of the downpipe forming machine - offering precision, efficiency, and sustainability - becomes ever more central to the pursuit of excellence in manufacturing.

Beyond technical specifications, real-world applications underscore the machine’s pivotal role in elevating business operations. Case studies reveal remarkable transformations in output quality and business scalability among businesses that have integrated downpipe forming machinery into their assembly lines. These success stories do not just highlight operational improvements; they underscore the machine's evolution from a mere tool to a cornerstone of strategic growth and innovation. In a sector characterized by stringent performance and durability demands, industry experts consistently advocate investing in technologically advanced and trustworthy equipment like the downpipe forming machine. The return on investment is not solely measured by immediate financial gains but also by the enhancement of product reliability and market reputation over time. As the construction landscape continues to evolve with an increasing emphasis on water conservation and sustainable practices, the integration of sophisticated machinery becomes an imperative. Conclusively, the downpipe forming machine represents more than a manufacturing instrument; it is a catalyst for efficiency, reliability, and innovation. Its integration within production systems not only meets but anticipates market needs, underscoring the imperative for businesses to adapt to the transforming industrial paradigm. As technological prowess and environmental responsibility become inextricably linked in consumer consciousness, the role of the downpipe forming machine - offering precision, efficiency, and sustainability - becomes ever more central to the pursuit of excellence in manufacturing.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products