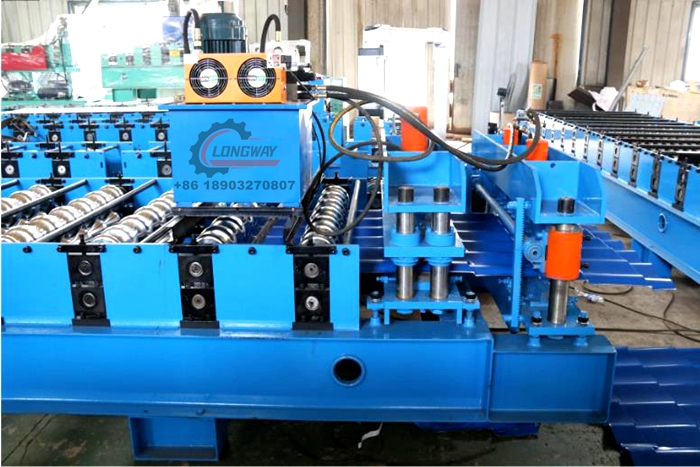

steel shutter door roll forming machine

The Steel Shutter Door Roll Forming Machine Transforming Metal into Versatile Security Solutions

In today’s world, security is paramount for both residential and commercial spaces. One of the most effective ways to enhance security is through the installation of robust shutter doors. Among the various manufacturing processes for these doors, the use of a steel shutter door roll forming machine has emerged as a game changer in the industry. This article explores the functionalities, advantages, and applications of this innovative machinery.

A steel shutter door roll forming machine is designed to produce steel shutter doors with precision and efficiency. The process begins with a coil of steel, which is fed into the machine. As the steel passes through a series of rollers, it is gradually shaped and formed into the desired profile. The ability to customize the thickness, width, and design of the doors makes this machine an essential asset for manufacturers. Unlike traditional methods, roll forming allows for continuous production, thereby increasing output while minimizing waste material.

One of the most significant advantages of using a steel shutter door roll forming machine is the durability of the final product. Steel is renowned for its strength and resistance to impact, corrosion, and extreme weather conditions. As a result, the shutter doors produced from this process do not just offer security; they are also built to withstand the elements, ensuring longevity and reduced maintenance costs for end-users.

steel shutter door roll forming machine

In terms of design versatility, the roll forming machine can create various styles and patterns of shutter doors. Manufacturers have the flexibility to design doors that not only serve as security solutions but also enhance the aesthetics of their surroundings. Customization options can include different colors, finishes, and additional features such as insulation and noise reduction, making them suitable for a wide range of applications, from retail shops to industrial warehouses.

Furthermore, the automated nature of roll forming machines significantly reduces labor costs and production time. Operators can easily set up the machine for different designs without extensive manual labor. Advanced technology allows for precise control over the forming process, ensuring that each door meets specified standards for quality and safety.

Additionally, the environmental impact of using roll forming technology is worth noting. The efficiency of the manufacturing process reduces energy consumption and waste material. Manufacturers can recycle leftover materials, contributing to a more sustainable production cycle. As industries become increasingly aware of their environmental footprint, the use of steel shutter door roll forming machines aligns well with green manufacturing practices.

In conclusion, the steel shutter door roll forming machine is a vital development in the production of security solutions. Its precision, efficiency, and ability to create durable and customizable products are unparalleled. As security concerns continue to rise globally, the demand for high-quality shutter doors will undoubtedly increase. Manufacturers who invest in this technology position themselves as leaders in the industry, capable of meeting diverse customer needs while promoting sustainability and innovation. Ultimately, the steel shutter door roll forming machine not only shapes metal but also plays a crucial role in securing properties and enhancing safety in our communities.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025