High-Quality Standing Seam Roll Formers Available from Trusted Manufacturers for Sale

Understanding Standing Seam Roll Formers for Sale A Comprehensive Guide

In the world of metal roofing and construction, standing seam roofs have gained immense popularity for their durability, weather resistance, and aesthetic appeal. The demand for standing seam panels continues to grow, leading to an increase in the availability of specialized machinery designed to produce these roofing components efficiently. Among the key equipment in this domain is the standing seam roll former. This article will delve into what standing seam roll formers are, how they function, and what to consider when searching for such machines for sale.

What is a Standing Seam Roll Former?

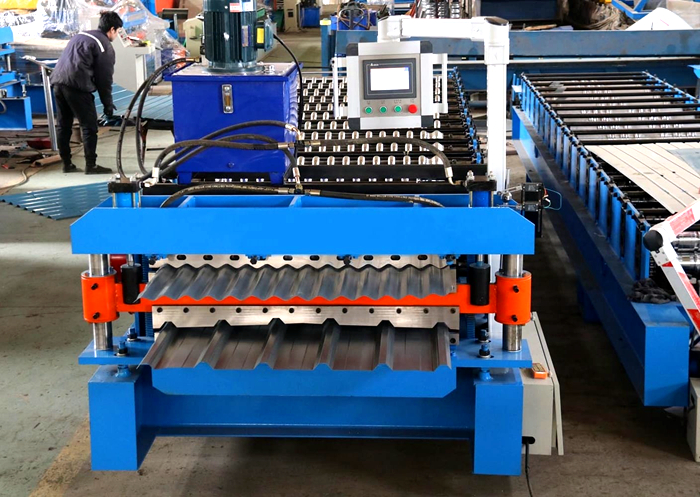

A standing seam roll former is a machine designed to fabricate standing seam metal roofing panels from metal coils. The process involves feeding a flat coil of metal—typically aluminum or steel—through a series of rollers that progressively shape and form the material into the desired profile. This equipment ensures that the seams of the roofing panels remain raised above the panels, providing superior resistance to water and wind, which is crucial for performance in harsh weather conditions.

How Does a Standing Seam Roll Former Work?

The working principle of a standing seam roll former is relatively straightforward

1. Material Loading The process begins with loading a coil of metal, often pre-painted or galvanized, onto the machine. 2. Feeding The coil is fed into the roll former, where it is drawn in through a series of rollers. 3. Forming As the metal passes through the rollers, it goes through several stages of shaping. Each roller contributes to bending the metal into the specific design and profile needed for standing seam panels. 4. Cutting Once the desired length of the panel is reached, the machine automatically cuts the panel to size. 5. Output The finished standing seam panels are then ejected from the machine, ready for installation.

The output can vary based on the specifications of the roll former, which might include features for adjusting the panel width and profile designs.

Considerations When Purchasing a Roll Former

standing seam roll former for sale factories

When looking to purchase a standing seam roll former, several factors should be taken into account to ensure you make an informed decision

1. Capacity and Speed Evaluate the production capacity and speed of the machine to ensure it meets your business’s demands. Higher production rates can significantly impact your operational efficiency.

2. Customization Options Some manufacturers offer customizable features to suit specific project needs. Look for a machine that can adapt to different panel sizes and designs.

3. Build Quality and Durability Invest in a roll former well-constructed from durable materials. A robust machine will perform better and require less maintenance over time.

4. Technical Support and Training Choose a supplier that offers technical support and training for operating the machine. This will help ensure that your team can maximize its capabilities efficiently.

5. Budget Determine your budget before exploring options. Different factories may offer a range of prices based on their machines' features and capabilities.

6. Supplier Reputation Research the reputation of manufacturers or suppliers. Reading customer reviews and case studies can provide insights into reliability and after-sale support.

Conclusion

Standing seam roll formers are pivotal in the metal roofing industry, facilitating the efficient production of durable roofing panels. By understanding their functionality and what to look for when purchasing, you can ensure that you invest in a machine that meets your production needs and helps elevate the quality of your projects. Whether you're a contractor, a manufacturer, or involved in the construction industry, a standing seam roll former can be an invaluable addition to your operations.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025