slitting line machine manufacturers

The Evolution and Significance of Slitting Line Machines Key Manufacturers and Trends

Slitting line machines play a crucial role in the metal processing industry, enabling operators to cut large coils of metal into narrower strips efficiently. With the rise of modern manufacturing processes, these machines have evolved significantly, leading to higher precision, productivity, and flexibility. This article delves into the significance of slitting line machines, key manufacturers in the industry, and the latest trends shaping their development.

Understanding Slitting Line Machines

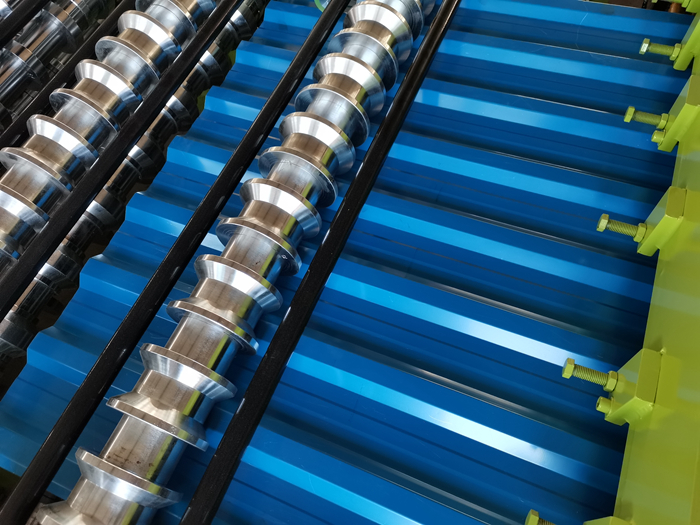

Slitting lines are designed to handle a variety of materials, including stainless steel, aluminum, and carbon steel. They work by uncoiling a large metal coil, feeding it through a series of rollers and blades, and then recoiling the newly cut strips. The importance of slitting line machines can’t be overstated; they help in optimizing resources, minimizing waste, and ensuring that the material dimensions meet specific requirements for further processing.

Key Manufacturers in the Industry

The market for slitting line machines is competitive, with several manufacturers standing out for their innovation and quality. Here are some notable names

1. SMS Group A German company, SMS Group is renowned for its state-of-the-art slitting lines. They are committed to providing solutions that are energy-efficient and designed for high-speed production.

2. Tenova Known for its comprehensive range of steelmaking equipment, Tenova develops slitting lines that maximize productivity while minimizing maintenance needs. Their technology focuses on user-friendliness and flexibility.

3. Mackintosh This manufacturer specializes in custom slitting lines tailored to meet specific customer needs. They utilize advanced technology, allowing operators to adjust settings easily for various widths and thicknesses.

4. Cisdi Group Based in China, Cisdi Group offers cost-effective slitting line solutions without compromising on quality. Their machines are designed for high performance, making them popular among Asian manufacturers.

slitting line machine manufacturers

5. M/s. FIMI This Italian company is known for its expertise in designing and manufacturing slitting lines that cater to a range of industries. FIMI emphasizes safety and operational efficiency in their machines.

Recent Trends in Slitting Line Technology

The slitting line industry is witnessing several trends aimed at enhancing efficiency, safety, and ecological consciousness

1. Automation With the integration of Industry 4.0 technologies, more manufacturers are adopting automated slitting lines. Automated systems reduce labor costs and improve precision, enabling facilities to run with minimal human intervention.

2. Smart Technology The incorporation of IoT (Internet of Things) in slitting lines allows for real-time monitoring and analysis. Manufacturers can track equipment performance, predict maintenance needs, and enhance overall productivity.

3. Energy Efficiency As industries strive for greener operations, slitting line manufacturers are focusing on creating machines that consume less energy. Innovations such as regenerative drives and improved hydraulic systems are becoming standard.

4. Customization Given the varying needs of different sectors, customization of slitting lines is increasingly important. Manufacturers are now offering tailor-made solutions that allow clients to select specific features based on their processing requirements.

5. Safety Features Enhanced safety mechanisms, including advanced guarding systems and emergency stop functionalities, are being integrated into slitting lines to protect operators and enhance workplace safety.

Conclusion

In conclusion, slitting line machines are vital to the metal processing industry, facilitating the efficient conversion of raw material into usable products. As the industry continues to evolve, key manufacturers are embracing technological advancements to meet the changing needs of clients. The trends toward automation, smart technology, energy efficiency, customization, and enhanced safety are reshaping the landscape, ensuring that slitting line machines remain an indispensable part of modern manufacturing processes. As this field continues to advance, stakeholders can expect even greater levels of efficiency and reliability from their slitting line solutions.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025