roof panel roll forming machine for sale factories

Exploring Roof Panel Roll Forming Machines for Sale A Comprehensive Overview

In the construction and manufacturing industries, efficiency and quality are paramount. One of the vital pieces of equipment that has revolutionized the production of roofing materials is the roof panel roll forming machine. These machines are designed to produce high-quality roofing panels with precision and speed, making them essential for factories and builders alike.

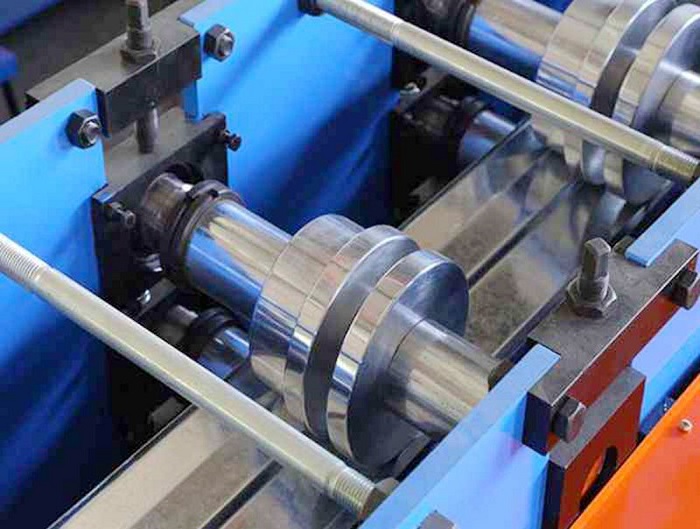

Roof panel roll forming machines are engineered to convert flat metal sheets into various roofing profiles. These machines utilize a continuous process where the metal is fed into a series of rollers that gradually shape it into the desired profile. The versatility of these machines allows for the production of a wide range of roofing panels, including standing seam, corrugated, and decorative styles, catering to diverse architectural needs.

One of the key advantages of roof panel roll forming machines is their ability to minimize waste. By cutting the metal to length only after it has been formed, manufacturers can ensure that every piece of material is utilized efficiently. This not only reduces material costs but also contributes to a more sustainable production process.

roof panel roll forming machine for sale factories

Furthermore, these machines are designed to enhance productivity. With the capability to produce large volumes of roofing panels in a relatively short period, factories can meet the increasing demand for roofing materials without compromising on quality. Advanced automation systems in modern roll forming machines allow for streamlined operations, from the initial feeding of metal sheets to the final packaging of finished products.

For businesses looking to invest in a roof panel roll forming machine, there are numerous options available from reputable manufacturers. These machines come in various sizes and configurations, allowing companies to choose the one that best fits their production needs and space constraints. Many manufacturers also offer customization options, enabling buyers to tailor the machines according to specific panel designs and production requirements.

When purchasing a roof panel roll forming machine, it is crucial to consider factors such as durability, ease of operation, and maintenance requirements. Investing in high-quality equipment ensures longevity and minimizes downtime, which is essential for maintaining a competitive edge in the market. Additionally, many manufacturers provide comprehensive support and training to help businesses get the most out of their machines.

In conclusion, roof panel roll forming machines are vital assets for factories specializing in roofing materials. Their efficiency, versatility, and ability to produce high-quality products make them a worthwhile investment for any business in the construction industry. As demand for innovative roofing solutions continues to grow, these machines will undoubtedly play a central role in meeting the needs of builders and homeowners alike. Investing in a roof panel roll forming machine can lead to increased productivity, reduced costs, and a stronger market presence, making it a strategic move for any forward-thinking company.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025