High-Quality Roof Panel Forming Machines | Durable & Efficient Solutions

The Growing Importance of Roof Panel Forming Machine Companies

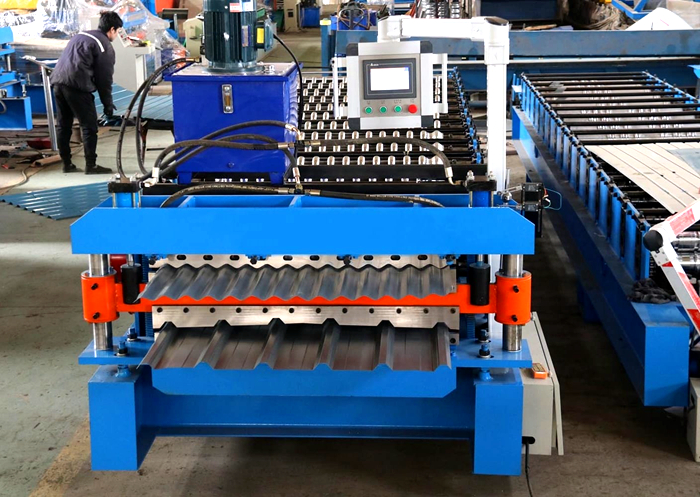

In the modern construction industry, efficiency and quality are paramount. With the increasing demand for durable and cost-effective building materials, roof panel forming machine companies have emerged as key players in the market. These companies specialize in the production of sophisticated machinery designed to manufacture roof panels with precision and speed, catering to the evolving needs of builders and contractors.

Roof panel forming machines are essential in producing a variety of roofing products, including metal panels, insulated panels, and more. The technology behind these machines has advanced significantly over the years, employing high-quality materials and automation to streamline the manufacturing process. This efficiency not only reduces production costs but also ensures that the roof panels meet stringent quality standards.

One of the primary advantages of employing roof panel forming machines is the ability to customize products according to specific project requirements. Companies in this sector offer a range of options, from different materials to varying thicknesses, widths, and lengths. This flexibility allows builders to obtain tailored solutions that fit their unique construction needs. Moreover, the precision of these machines ensures that the components are uniform and fit together seamlessly, ultimately enhancing the integrity and aesthetic of the structure.

roof panel forming machine companies

The contribution of roof panel forming machine companies goes beyond just manufacturing efficiency. They also play a crucial role in promoting sustainability within the construction industry. Many manufacturers are now focusing on producing eco-friendly materials and developing energy-efficient machines. For instance, advancements in technology allow for the recycling of scrap metal generated during the manufacturing process, minimizing waste and contributing to a greener environment. Moreover, the insulated panels produced by these machines help improve energy efficiency in buildings, reducing heating and cooling costs.

In addition to environmental benefits, roof panel forming machine companies enhance construction safety. The automation of the panel production process reduces the need for manual labor, which can often be dangerous at construction sites. With machines handling the heavy lifting and precise cutting, workers are less exposed to hazardous conditions, making the entire process safer.

As the global construction market continues to expand, the demand for roof panel forming machines is expected to rise significantly. Markets in developing countries are experiencing a boom in infrastructure development, which has resulted in a surge of interest in high-quality, efficient roofing solutions. Roof panel forming machine companies that can adapt to these changing market dynamics and offer innovative, reliable products will be well-positioned to capitalize on this trend.

In conclusion, roof panel forming machine companies are integral to the modern construction landscape. Their ability to produce high-quality, customizable roofing solutions while promoting sustainability and safety makes them invaluable partners for builders and contractors. As technology continues to evolve, these companies are likely to remain at the forefront of the industry, driving innovation and efficiency in roofing material production. By investing in advanced machinery and focusing on customer needs, roof panel forming machine companies will continue to shape the future of construction.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025