Reliable Drywall Roll Forming Machine Solutions for Efficient Construction Projects

The Evolution of Drywall Roll Forming Machine Companies

In the construction and interior design industries, drywall serves as one of the most essential materials for creating interior walls and ceilings. As the demand for efficient and high-quality drywall solutions increases, the role of drywall roll forming machine companies has gained significant importance. These companies are at the forefront of innovation, producing advanced machinery that simplifies the manufacturing process and enhances the overall quality of drywall products.

What is a Drywall Roll Forming Machine?

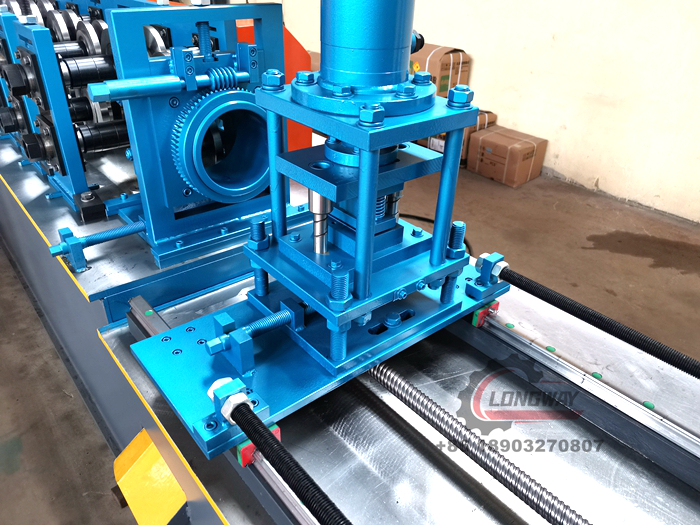

A drywall roll forming machine is specialized equipment designed to produce drywall sheets from raw materials. These machines can efficiently create standardized or custom-sized drywall panels with precise thickness and lengths. The roll forming process involves feeding raw gypsum board or other compatible materials through a series of rollers that shape the material into the desired form. This automation not only speeds up production but also minimizes waste, making it an attractive option for manufacturers.

Benefits of Drywall Roll Forming Machines

One of the primary advantages of using drywall roll forming machines is their efficiency. Traditional methods of producing drywall are labor-intensive and time-consuming, often resulting in inconsistencies and defects in the final product. Roll forming machines streamline the process, allowing manufacturers to meet growing demand without sacrificing quality. Furthermore, advanced machines equipped with digital controls offer high precision and repeatability, ensuring that each panel meets industry standards.

Another significant benefit is cost reduction. By automating the manufacturing process, companies can lower labor costs and reduce material wastage significantly. The initial investment in a drywall roll forming machine may be substantial, but the long-term savings in production efficiency and reduced operational costs make it a wise decision for many businesses.

drywall roll forming machine company

The Role of Innovation

The drywall industry has seen significant advancements in technology, and companies that produce drywall roll forming machines are no exception. Innovations such as computer numerically controlled (CNC) systems and artificial intelligence (AI) integration allow for enhanced automation and increased production capabilities. Moreover, many modern machines are designed to accommodate a wider variety of materials beyond traditional gypsum, including eco-friendly options that align with sustainability goals increasingly prioritized in the construction sector.

Global Market Trends

As urbanization increases and the construction industry expands, the global market for drywall and associated machinery is poised for growth. Companies focused on developing and producing drywall roll forming machines must stay ahead of the curve by continuously adapting to technological advancements and changing customer needs. The rise of prefab construction and modular building methods is also influencing the design and manufacturing of drywall products, leading to more innovative solutions in machinery production.

Moreover, companies in this sector are increasingly prioritizing sustainability. As building regulations become more stringent regarding environmental impact, drywall roll forming machine companies are incorporating eco-friendly practices into their operations. This includes using recyclable materials and optimizing energy consumption, thus appealing to a growing market of environmentally conscious builders.

Conclusion

Drywall roll forming machine companies play a pivotal role in the evolving landscape of the construction industry. By embracing innovation, enhancing production efficiency, and promoting sustainability, these companies are not just meeting the demands of today's market but also setting the stage for future advancements. As the industry continues to grow, the importance of high-quality, efficient machinery will remain a driving force behind successful drywall manufacturing, ultimately contributing to the creation of safer, more sustainable buildings.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025