Metal Siding Solutions Innovator Focused on Quality and Efficiency in Manufacturing

The Rise of Metal Siding Machine Companies in Modern Construction

In recent years, the construction industry has seen a significant transformation, driven by advancements in technology and an overall shift towards sustainability. One notable aspect of this evolution is the increasing prevalence and demand for metal siding. This trend has paved the way for the emergence of specialized metal siding machine companies that cater to the unique needs of builders, contractors, and architects alike.

Metal siding has gained attention for its durability, low maintenance requirements, and aesthetic versatility. Unlike traditional materials such as wood or vinyl, metal siding offers exceptional resistance to weathering, pests, and rot. This characteristic not only extends the lifespan of buildings but also reduces the need for frequent repairs and replacements. Furthermore, metal siding is available in a wide range of finishes and colors, allowing designers to create striking architectural statements that blend style with functionality.

The Rise of Metal Siding Machine Companies in Modern Construction

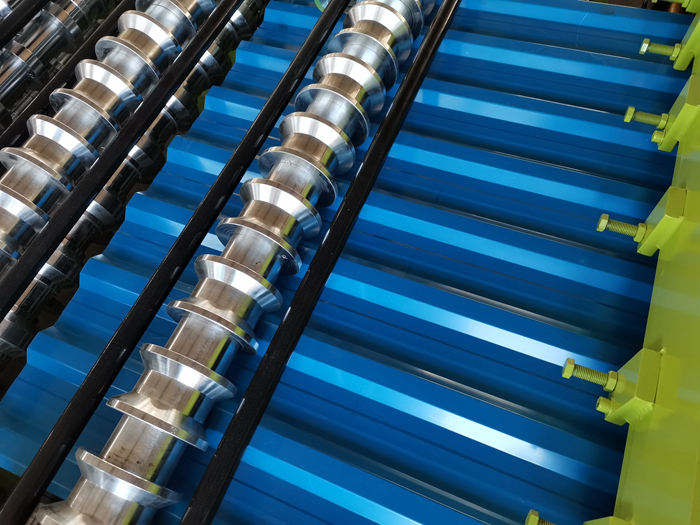

One of the key innovations in metal siding machinery is the use of advanced technologies such as Computer Numerical Control (CNC) and automated feeding systems. These technologies enhance efficiency, reduce waste, and ensure a high level of accuracy during production. For businesses looking to scale their operations, investing in state-of-the-art metal siding machines can result in substantial cost savings and increased output, ultimately leading to higher profit margins.

metal siding machine company

Metal siding machine companies are also embracing sustainable practices, aligning with the growing trend towards environmentally conscious construction. Many of these companies utilize recycled materials in their manufacturing processes, reducing the overall carbon footprint of metal siding. Additionally, advancements in energy efficiency within the machinery itself—such as lower power consumption and improved performance—contribute to a more sustainable production lifecycle.

Moreover, the rise of metal siding machine companies has spurred job creation in the manufacturing sector. Skilled workers are needed to operate, maintain, and innovate within this burgeoning industry. As these companies grow, they are also forging partnerships with schools and training programs to ensure a steady pipeline of knowledgeable employees equipped to navigate the complexities of modern manufacturing.

The metal siding machine industry is not merely about manufacturing; it also encompasses a range of support services. Companies frequently provide training and technical assistance to ensure that operators can maximize the capabilities of the machines. Furthermore, many metal siding machine manufacturers offer customizable solutions, tailoring their equipment to meet the specific needs of clients—be it the size of the project or the specific design requirements.

In conclusion, metal siding machine companies are playing a pivotal role in the transformation of the construction industry. By producing efficient, high-quality siding materials and embracing sustainable practices, they contribute not only to the aesthetic and structural integrity of buildings but also to the overall advancement of the construction sector. As this industry continues to grow, it is poised to redefine the future of building design and construction, ensuring that metal siding remains at the forefront of architectural innovation.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025