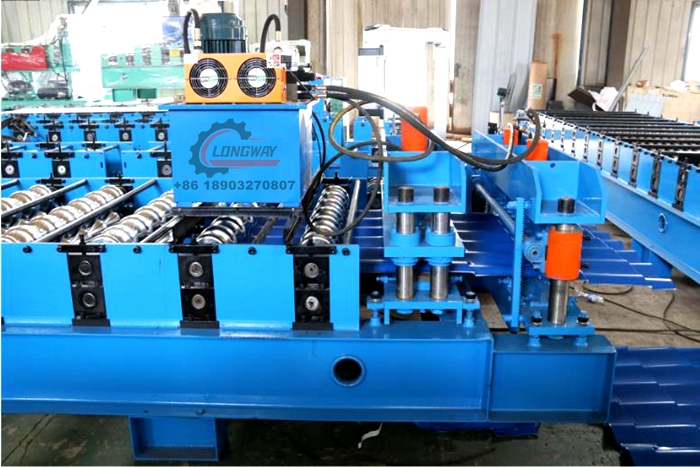

ibr roll forming machine for sale company

Exploring the Benefits of IBR Roll Forming Machines for Sale

In the ever-evolving landscape of metal fabrication, the demand for high-quality, durable building materials continues to rise. One of the most efficient solutions to meet these demands is the IBR (Inverted Box Rib) roll forming machine. These machines are essential for producing IBR sheets, which are widely used in the roofing and siding industries. This article delves into the advantages of IBR roll forming machines, especially for businesses looking to invest in such machinery for enhanced productivity and profitability.

Understanding IBR Roll Forming Machines

IBR roll forming machines are specially designed to create IBR sheets characterized by their unique ribbed structure. This structure not only adds aesthetic appeal but also enhances the strength and durability of the sheets, making them ideal for various applications, including commercial buildings, warehouses, and residential properties. These machines operate by feeding flat metal coils through a series of rollers that progressively shape the metal into the desired profile. The final product is lightweight, strong, and suitable for diverse roofing and cladding uses.

Key Advantages of IBR Roll Forming Machines

1. Efficiency and Speed One of the primary benefits of using an IBR roll forming machine is its efficiency. Once set up, these machines can produce large quantities of IBR sheets quickly. This high-speed output can significantly reduce manufacturing time, allowing businesses to meet tight deadlines and fulfill larger orders.

2. Cost-Effectiveness Investing in an IBR roll forming machine can lead to substantial cost savings in the long run. While the initial investment might seem considerable, the automated production process minimizes labor costs and waste, enhancing overall profitability. Moreover, the durability of the produced sheets means that fewer replacements are needed over time, further reducing expenses.

ibr roll forming machine for sale company

3. Versatility IBR roll forming machines are highly versatile. They can be adapted to produce various sheet sizes and profiles to meet specific client requirements. This flexibility allows manufacturers to cater to a broader market, accommodating different construction styles and preferences.

4. Quality Control With advanced technology integrated into modern IBR roll forming machines, maintaining quality control has become easier than ever. These machines offer precise measurements and consistent output, ensuring that every sheet produced meets industry standards. This not only builds trust with clients but also reinforces a company's reputation in a competitive market.

5. Environmental Benefits Utilizing an IBR roll forming machine contributes to sustainability efforts. The efficient production processes reduce material waste, and the longevity of the products lowers the need for frequent replacements. Additionally, IBR sheets can be made from recyclable materials, aligning production practices with eco-friendly initiatives.

Choosing a Reliable IBR Roll Forming Machine Supplier

For businesses looking to invest in an IBR roll forming machine, selecting a reputable supplier is crucial. It is essential to assess the quality of the machines, after-sales service, and warranty options. A reliable supplier should also offer technical support and training to ensure that operators can maximize the machine's capabilities.

In conclusion, an IBR roll forming machine represents an intelligent investment for companies in the metal fabrication and construction industries. With its efficiency, cost-effectiveness, versatility, and quality output, it can help businesses thrive in a competitive market. As demand for high-quality roofing solutions continues to grow, equipping your business with this advanced technology can pave the way for future success. Whether expanding an existing product line or entering new markets, the benefits of IBR roll forming machines are undeniable, making them a worthwhile consideration for any forward-thinking company.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025