gutter machine factory

Gutter Machine Factory Innovation in Gutter Production

In the realm of modern construction and home improvement, the importance of effective drainage systems cannot be overstated. Among the pivotal components of such systems are gutters, which serve the critical function of channeling rainwater away from roofs, thereby protecting buildings from potential water damage. As demand for more efficient and customized gutter solutions grows, the gutter machine factory emerges as a vital player in this industry, integrating advanced technology with traditional manufacturing processes.

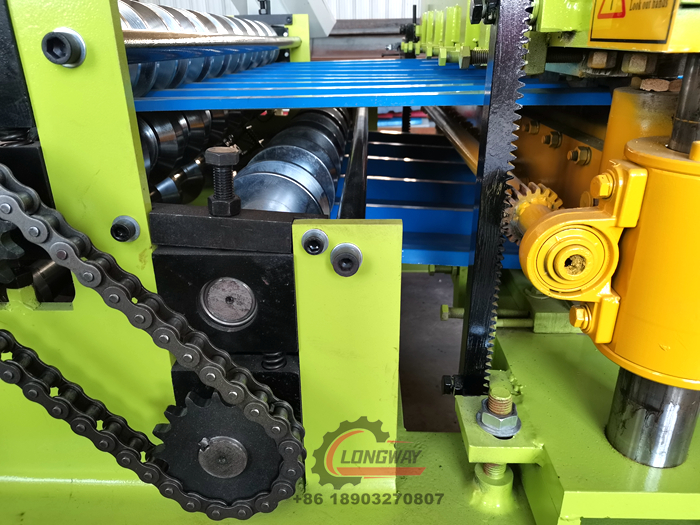

A gutter machine factory specializes in the production of machines designed specifically for the fabrication of gutters and downspouts. These machines vary in design and capability, with some dedicated to producing seamless gutters, while others offer versatility to create different profiles and sizes. The evolution of gutter machinery has been influenced by ongoing technological advancements, making the production of high-quality gutters quicker and more cost-effective than ever before.

At the heart of any successful gutter machine factory is the commitment to innovation. Modern factories utilize computer numerical control (CNC) technology, offering unparalleled precision in manufacturing. This allows for the consistent production of gutters that fit perfectly with any roofing system. Notably, seamless gutter machines eliminate the need for joints, significantly reducing the risk of leaks and enhancing the overall durability of the gutter system.

Furthermore, many factories now prioritize the use of high-quality materials in their manufacturing processes. Whether it’s aluminum, copper, or steel, the choice of material directly impacts the performance and longevity of the gutters. Gutter machine manufacturers are also keen on adopting eco-friendly practices, using recyclable materials and implementing energy-efficient processes to reduce their environmental footprint. This is particularly important as consumers become more environmentally conscious and seek sustainable building solutions.

gutter machine factory

Additionally, customization is a key trend in the gutter industry. Many customers require specific designs that cater to unique architectural features, and gutter machine factories are adapting to meet these needs. Advanced software allows for quick modifications in design, enabling manufacturers to produce gutters that not only function well but also complement the aesthetic appeal of a building. This adaptability positions gutter machine factories as essential partners to both contractors and homeowners alike.

Training and expertise in operating these sophisticated machines are equally important. Gutter machine factories often invest in comprehensive training programs for their personnel. Skilled machine operators can maximize efficiency, minimize waste, and ensure that each gutter produced meets stringent quality standards. Investing in human capital is crucial for the long-term success of these factories.

Distribution channels also play a significant role in the growth of gutter machine factories. Collaborating with distributors ensures that products reach the market swiftly and efficiently, satisfying consumer demand. With the expansion of e-commerce, gutter machine factories are adapting their sales strategies to cater to a global market, enhancing their reach and fostering growth.

In conclusion, gutter machine factories stand at the forefront of an evolving industry, driven by innovation, customization, and sustainability. As the demand for effective water management solutions continues to rise, these factories will play an indispensable role in shaping the future of gutter production. By marrying advanced technology with skilled craftsmanship, they are not only producing essential components for construction but are also contributing to the development of efficient and environmentally friendly building practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025