Downspout Roll Forming Machine | High Efficiency & Precision Metal Fabrication

The Importance of Downspout Roll Forming Machines in Modern Manufacturing

In the world of manufacturing, efficiency and precision are paramount. One of the key innovations that have transformed the production of various metal products is the downspout roll forming machine. This specialized equipment is designed to streamline the creation of downspouts, which play a crucial role in managing rainwater and protecting properties from water damage.

Understanding Downspouts

Before delving into the specifics of downspout roll forming machines, it is essential to understand what downspouts are. Downspouts are vertical pipes that direct rainwater from the gutters of a building to the ground or drainage systems. Properly functioning downspouts help prevent erosion, flooding, and deterioration of building foundations. Given the critical nature of their function, manufacturers need reliable and efficient methods to produce these components.

The Roll Forming Process

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into the desired cross-section. The process entails feeding a coil of metal through a series of rollers, which incrementally bend the material into the final shape without cutting or removing any stock. This technique is particularly advantageous for producing downspouts, as it allows for high-volume production with minimal waste.

Advantages of Downspout Roll Forming Machines

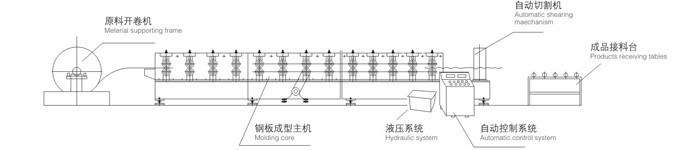

downspout roll forming machine

1. Efficiency Downspout roll forming machines can operate at high speeds, significantly reducing production time compared to traditional manufacturing methods. This efficiency allows manufacturers to meet demand quickly and cater to custom orders without extensive delays.

2. Cost-Effectiveness The continuous nature of roll forming lowers material costs as it generates minimal waste. Furthermore, the reduced labor costs and faster production times lead to overall savings, making it a financially viable option for manufacturers.

3. Precision The ability to maintain tight tolerances during the roll forming process results in high-quality downspouts that fit seamlessly into existing gutter systems. This precision ensures that products meet industry standards and customer expectations.

4. Versatility Modern downspout roll forming machines can produce a variety of shapes and sizes, accommodating various architectural designs. They can also be configured to work with different materials, including aluminum, galvanized steel, and copper, broadening the scope for manufacturers and enabling them to serve diverse markets.

5. Custom Solutions Many manufacturers opt for customized downspout roll forming machines, allowing them to create specific designs unique to their customers’ needs. This flexibility fosters innovation and helps businesses stand out in a competitive market.

Conclusion

In summary, downspout roll forming machines play a vital role in the metal fabrication industry. Their efficiency, cost-effectiveness, precision, versatility, and ability to accommodate custom solutions make them invaluable for producing high-quality downspouts. As demand for efficient rainwater management systems continues to grow, the importance of these machines will only increase, driving advancements in manufacturing processes and promoting sustainable practices in construction and design. For manufacturers looking to optimize their production capabilities, investing in a downspout roll forming machine is a strategic move that can yield significant returns in quality, efficiency, and customer satisfaction.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025