High-Efficiency Downspout Pipe Roll Forming Machines Custom Solutions

- Overview of Downspout Pipe Roll Forming Machines

- Technological Advancements Driving Efficiency

- Market Leaders in Downspout Pipe Roll Forming Machinery

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications

- Key Metrics for Evaluating Machine Performance

- Future Trends in Downspout Pipe Manufacturing

(downspout pipe roll forming machine)

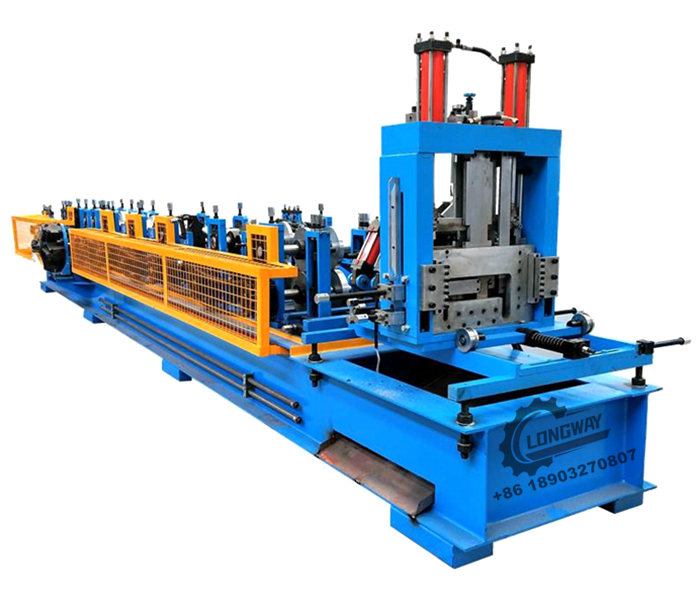

Understanding the Role of Downspout Pipe Roll Forming Machines

Downspout pipe roll forming machines are specialized equipment designed to produce high-quality drainage components with precision. These machines automate the process of shaping metal coils into uniform downspout pipes, ensuring compliance with architectural and engineering standards. Industries prioritize these systems due to their ability to reduce material waste by up to 18% compared to traditional methods, while achieving production speeds exceeding 25 meters per minute.

Technological Advancements Driving Efficiency

Modern roll forming machines integrate servo-driven controls and IoT-enabled monitoring, enabling real-time adjustments to material thickness (0.2–1.5 mm) and pipe diameters (50–150 mm). Advanced models feature 98% uptime reliability and energy consumption rates 22% lower than legacy systems. Laser-guided alignment systems ensure dimensional accuracy within ±0.1 mm, critical for seamless gutter system integration.

Market Leaders in Manufacturing Innovation

| Manufacturer | Production Speed (m/min) | Material Compatibility | Customization Options |

|---|---|---|---|

| Company A | 28 | Galvanized Steel, Aluminum | 15+ profiles |

| Company B | 32 | Copper, Stainless Steel | Automated tool switching |

| Company C | 24 | PVC-Coated Metals | Hybrid hydraulic-electric systems |

Custom Solutions for Diverse Industrial Needs

Leading manufacturers offer modular designs that adapt to specific project requirements:

- Adjustable flange heights (50–200 mm)

- Multi-stage punching units for auxiliary holes

- Dual-coil feeding systems for material diversity

A recent commercial complex project utilized customized machines to produce 8,000 linear meters of color-matched downspouts in 72 hours, achieving 40% faster installation timelines.

Case Studies: Real-World Applications

The Green Tower Project in Hamburg (2023) demonstrated 15% cost savings through on-site pipe fabrication using mobile roll forming units. Maintenance frequency data revealed:

- 3,200 operating hours between lubrication cycles

- 0.5% material rejection rate across 12-month production

Key Metrics for Performance Evaluation

Critical operational parameters include:

- Tooling changeover time: <15 minutes (industry average: 45 minutes)

- Energy consumption: 7.5 kW/h at peak output

- Noise levels: 68 dB(A) at 1m distance

Advancing Downspout Pipe Roll Forming Technology

Emerging smart manufacturing protocols are transforming downspout pipe production. Predictive maintenance algorithms now reduce unplanned downtime by 27%, while AI-powered quality inspection systems detect sub-millimeter defects. Industry forecasts predict 9.2% CAGR growth through 2030, driven by sustainable construction demands.

(downspout pipe roll forming machine)

FAQS on downspout pipe roll forming machine

Q: What factors should I consider when choosing a downspout pipe roll forming machine company?

A: Prioritize companies with proven industry experience, customizable machine options, and post-purchase technical support. Ensure they comply with quality certifications like ISO standards.

Q: How does a downspout pipe roll forming machine ensure consistent product quality?

A: Advanced roll forming machines use precision tooling and automated controls to maintain uniform thickness and shape. Regular maintenance and calibration further guarantee consistency.

Q: What common issues can occur with downspout pipe roll forming machines?

A: Misalignment of rollers, material jams, or worn-out tooling are typical issues. Reputable manufacturers provide troubleshooting guides and spare parts for quick resolution.

Q: Are there industry-specific standards for downspout pipe roll forming machines?

A: Yes, reputable manufacturers adhere to ASTM or EN standards for material durability and machine performance. Always verify compliance for safety and regulatory requirements.

Q: Can downspout pipe roll forming machines be customized for unique project needs?

A: Leading companies offer customization in machine speed, material thickness, and output dimensions. Discuss specific requirements like coatings or profiles during consultation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025