aluminium roofing sheet making machine companies

The Rise of Aluminium Roofing Sheet Making Machines A New Era in Construction Materials

In recent years, the construction industry has witnessed a significant shift towards more sustainable and efficient building materials. Among these, aluminium has emerged as a popular choice for roofing solutions, thanks to its durability, lightweight nature, and resistance to corrosion. This trend has given rise to a variety of companies specializing in the manufacturing of aluminium roofing sheet making machines, which facilitate the production of high-quality roofing materials for a diverse range of applications.

Aluminium roofing sheets are not only aesthetically pleasing but also offer superior performance compared to traditional materials like steel or asphalt. Their lightweight properties make them ideal for both residential and commercial buildings, reducing the overall load on structures and allowing for easier installation. Moreover, aluminium does not rust, ensuring a longer lifespan and lower maintenance costs. As a result, the demand for aluminium roofing sheets has surged, prompting the development of advanced manufacturing machinery to cater to this growing market.

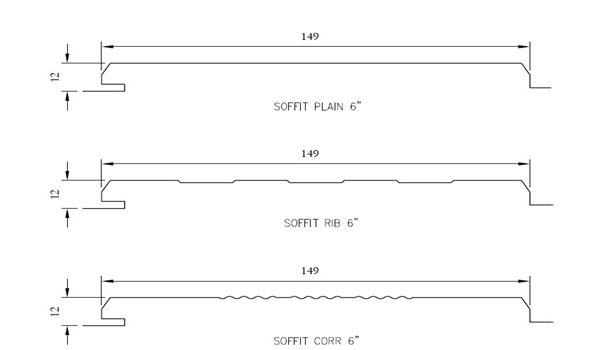

Companies involved in the production of aluminium roofing sheet making machines are innovating rapidly, integrating advanced technologies such as automation and computer numerical control (CNC) to enhance productivity and precision. These machines are designed to transform aluminium coils into roofing sheets in a variety of profiles and thicknesses, allowing manufacturers to meet specific customer requirements. This flexibility in production not only caters to mainstream roofing designs but also opens up avenues for custom architectural projects.

One of the key advantages of investing in aluminium roofing sheet making machines is the cost-effectiveness they offer. Traditionally, manufacturers had to rely on outsourcing their production, which often led to longer lead times and increased costs. However, with in-house machinery, companies can streamline their operations, reducing dependence on third-party suppliers. This vertical integration allows for better control over the manufacturing process, leading to enhanced quality assurance and quicker turnaround times.

aluminium roofing sheet making machine companies

Furthermore, the environmental benefits of aluminium roofing sheets cannot be overlooked. Aluminium is 100% recyclable, and the production processes involved in making these sheets have become increasingly energy-efficient. Many companies have adopted eco-friendly practices, ensuring that their machinery operates in compliance with environmental regulations. This focus on sustainability not only appeals to environmentally-conscious consumers but also positions manufacturers favorably in a competitive market.

Several notable companies have emerged as leaders in the aluminium roofing sheet making machine sector. These enterprises invest heavily in research and development, ensuring that their products incorporate the latest technological advancements. They also provide comprehensive training and support for their clients, helping them maximize the efficiency of their machinery. This commitment to customer satisfaction has fostered long-term relationships and established trust within the industry.

In addition to large-scale manufacturers, there has also been a rise in small to medium-sized businesses entering the market. These companies often focus on niche segments, offering specialized machines that cater to specific roofing needs, such as intricate designs for residential homes or robust solutions for industrial complexes. This diversity in the market enhances competition, leading to continuous improvements in technology and machine capabilities.

As the demand for sustainable building materials continues to grow, the aluminium roofing sheet making machine industry is poised for further expansion. Innovations in machinery will likely lead to even greater efficiencies and capabilities, enabling manufacturers to meet the evolving needs of architects and builders. With the construction industry increasingly prioritizing sustainability, durability, and aesthetics, aluminium roofing sheets and their manufacturing machinery represent a significant opportunity for growth.

In conclusion, companies that specialize in aluminium roofing sheet making machines are playing a crucial role in the evolution of the construction materials market. Their focus on innovation, efficiency, and sustainability aligns with the demands of contemporary architecture and environmental consciousness. As we move forward, it will be exciting to see how these advancements continue to shape the roofing industry, paving the way for a greener and more resilient built environment.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025