Noticias

-

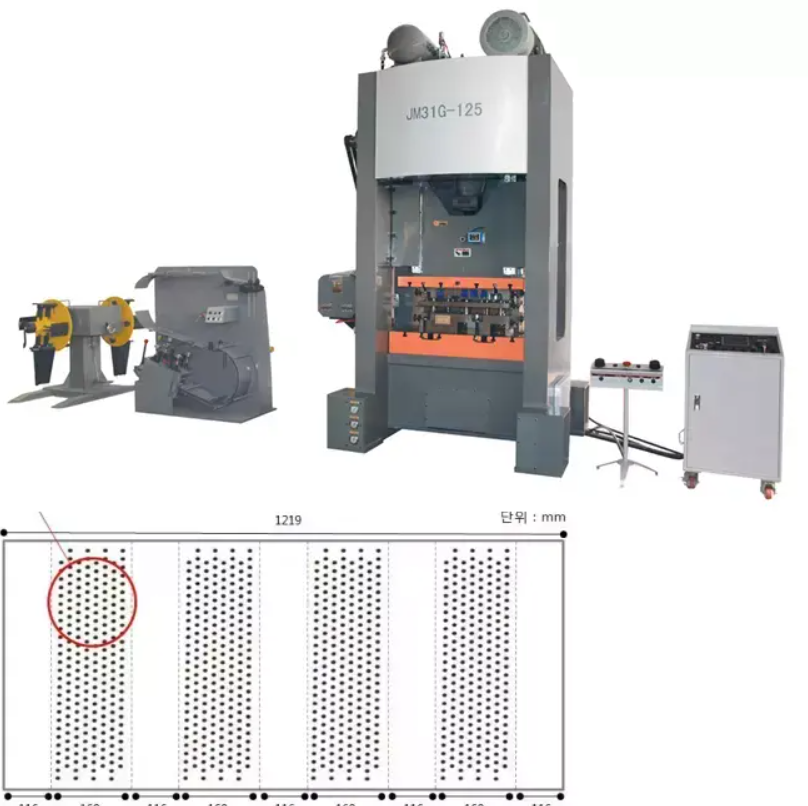

To roll or to stamp—that is the question. Your mission is to source a high quality, custom steel part to be manufactured efficiently at a relatively low cost. As you well know, there are a variety of different metal forming techniques when sourcing a new project. But how do you choose between two popular methods, roll forming and stamping?Leer más

To roll or to stamp—that is the question. Your mission is to source a high quality, custom steel part to be manufactured efficiently at a relatively low cost. As you well know, there are a variety of different metal forming techniques when sourcing a new project. But how do you choose between two popular methods, roll forming and stamping?Leer más -

Roll forming means giving shapes to sheeted metal, mostly round and conical. But roll forming also allows us to create angled shapes like rectangles and squares. They can be fitted with crowning systems, software, controllers, to deliver unmatched precision and quality. Because of their flexibility and versatility, plate rollers are a much-wanted machine system, in plants manufacturing everything from home appliances, to the ones we take to space.Leer más

Roll forming means giving shapes to sheeted metal, mostly round and conical. But roll forming also allows us to create angled shapes like rectangles and squares. They can be fitted with crowning systems, software, controllers, to deliver unmatched precision and quality. Because of their flexibility and versatility, plate rollers are a much-wanted machine system, in plants manufacturing everything from home appliances, to the ones we take to space.Leer más -

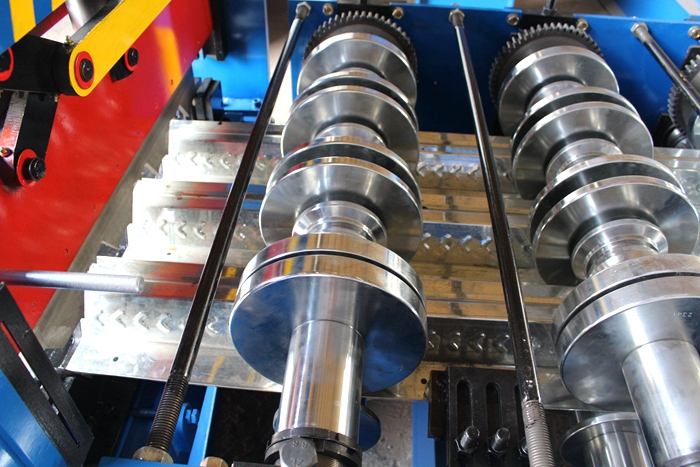

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.Leer más

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.Leer más -

A roll former is a machine that may seem tremendously complex, with its various stations and high speeds. However, understanding how it works is valuable as it can perform a unique function, consistently creating identical end products that meet the strictest specifications.Leer más

A roll former is a machine that may seem tremendously complex, with its various stations and high speeds. However, understanding how it works is valuable as it can perform a unique function, consistently creating identical end products that meet the strictest specifications.Leer más -

Roll Forming Machine is a processing machine that passes rolled steel or other long strips of metal through a series of Hardened Steel Rollers, which are controlled using a pre-set PLC code, to achieve a specific processing operation on the sheet metal at each station to produce a specific metal part. It is characterised by high progress, high speed, low scrap and one-off forming. It is therefore a very economical way of processing and is often used for the processing of large quantities of parts.Leer más

Roll Forming Machine is a processing machine that passes rolled steel or other long strips of metal through a series of Hardened Steel Rollers, which are controlled using a pre-set PLC code, to achieve a specific processing operation on the sheet metal at each station to produce a specific metal part. It is characterised by high progress, high speed, low scrap and one-off forming. It is therefore a very economical way of processing and is often used for the processing of large quantities of parts.Leer más -

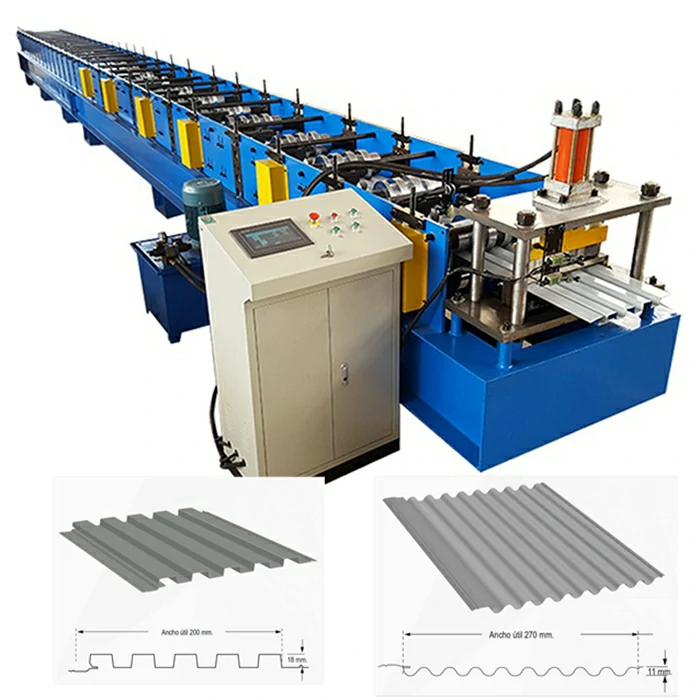

A roll forming machine is a type of machine used to produce all kinds of metal sheets used in roofing houses or walls for large and small projects or factories, with many beautiful designs and durable profiles.Leer más

A roll forming machine is a type of machine used to produce all kinds of metal sheets used in roofing houses or walls for large and small projects or factories, with many beautiful designs and durable profiles.Leer más -

The main difference is that while rolling forces the metal to flow into a different shape, sheet metal forming works by causing deformation in the material overall, with minimal effect on the grain structure or the thickness of the material.Leer más

The main difference is that while rolling forces the metal to flow into a different shape, sheet metal forming works by causing deformation in the material overall, with minimal effect on the grain structure or the thickness of the material.Leer más -

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-prohibitive altogether. The up-front price tag tends to blind them to literal down-the-line savings. That’s right -- if your project fits, a roll form manufacturer can actually optimize your spending and get your parts out the door sooner and for less money per part.Leer más

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-prohibitive altogether. The up-front price tag tends to blind them to literal down-the-line savings. That’s right -- if your project fits, a roll form manufacturer can actually optimize your spending and get your parts out the door sooner and for less money per part.Leer más -

IPlastic Injection Molding Machines Types and Benefitsnjection and extrusion molding are two popular plastic molding methods in the industrial and manufacturing sector that are used to make products with varying shapes and sizes. Depending on the product and the customer, both processes have their individual strengths. Midstate Mold & Engineering is strictly a plastic injection molding manufacturing company, but it is always helpful to our customers to know the difference between each process.Leer más

IPlastic Injection Molding Machines Types and Benefitsnjection and extrusion molding are two popular plastic molding methods in the industrial and manufacturing sector that are used to make products with varying shapes and sizes. Depending on the product and the customer, both processes have their individual strengths. Midstate Mold & Engineering is strictly a plastic injection molding manufacturing company, but it is always helpful to our customers to know the difference between each process.Leer más -

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Leer más

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Leer más -

The main difference between injection molding and extrusion molding is that injection molding is highly restrictive molding by injection mold, and extrusion is semi-restrictive molding by extrusion die.Leer más

The main difference between injection molding and extrusion molding is that injection molding is highly restrictive molding by injection mold, and extrusion is semi-restrictive molding by extrusion die.Leer más -

Blow moulding is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. At Central Machinery and Plastic Products, we use extrusion blow moulding (EBM). EBM bottles are easily identifiable by their pinch line across the base of the bottle. This line is created as the mould cavity closes on the parison and the tail is trimmed off.Leer más

Blow moulding is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. At Central Machinery and Plastic Products, we use extrusion blow moulding (EBM). EBM bottles are easily identifiable by their pinch line across the base of the bottle. This line is created as the mould cavity closes on the parison and the tail is trimmed off.Leer más