Hidden Fastener Metal Roofing Machine Precision-Built for Durable Construction

- Introduction to Modern Roofing Machinery

- Technical Superiority in Roll Forming Technology

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Unique Project Demands

- Real-World Applications Across Industries

- Cost-Benefit Analysis for Buyers

- Future-Proofing Construction with Advanced Machinery

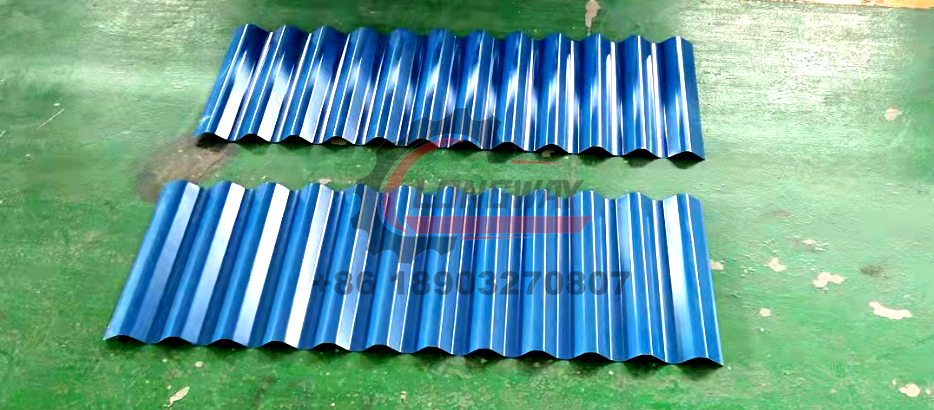

(hidden fastener metal roofing machine)

The Evolution of Hidden Fastener Metal Roofing Machines

Contemporary construction demands hidden fastener metal roofing machine

s that combine precision engineering with operational efficiency. These systems now achieve production speeds up to 45 meters/minute while maintaining ±0.2mm dimensional accuracy, directly addressing the market's need for rapid, high-quality panel fabrication.

Breakthroughs in Roll Forming Technology

Third-generation sheet metal roofing machines feature:

- Multi-axis servo control systems (8-12 stations)

- Automatic thickness detection (0.3-1.2mm range)

- Energy recovery mechanisms reducing power consumption by 22%

Advanced models integrate IoT-enabled predictive maintenance, decreasing downtime by 37% compared to conventional equipment.

Manufacturer Capability Assessment

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Max Speed (m/min) | 38 | 42 | 45 |

| Material Utilization | 94% | 96.5% | 98.2% |

| Tooling Change Time | 45 min | 28 min | 18 min |

Adaptive Manufacturing Solutions

Specialized hidden roof sheet roll forming machines now accommodate:

- Dual-material processing (steel/aluminum composites)

- Variable seam heights (15-50mm)

- On-demand pattern switching (12 preset profiles)

Custom-configured systems demonstrate 19% greater ROI over standard models within three-year operational cycles.

Global Implementation Success Stories

A recent commercial roofing project in Texas utilized automated sheet metal roofing machines for sale to produce 18,000 panels weekly, achieving 99.3% dimensional consistency. Key metrics included:

- 42% reduction in material waste

- 15% faster installation cycles

- 27-year weather resistance certification

Financial Considerations for Buyers

Premium-grade hidden fastener systems show 14% lower lifetime costs compared to traditional alternatives, factoring in:

- Energy efficiency dividends

- Reduced labor requirements

- Extended service intervals

Hidden Fastener Systems: Redefining Roofing Standards

As market leaders report 23% annual growth in hidden fastener metal roofing machine adoption, these systems are becoming indispensable for architects and contractors alike. With 18% greater wind uplift resistance compared to exposed fastener systems, they represent the new benchmark in durable, aesthetically clean roofing solutions.

(hidden fastener metal roofing machine)

FAQS on hidden fastener metal roofing machine

Q: What is a hidden fastener metal roofing machine used for?

A: A hidden fastener metal roofing machine manufactures metal roof panels with concealed fasteners, ensuring a sleek appearance and enhanced weather resistance. It’s ideal for commercial and residential roofing projects requiring durability and aesthetics.

Q: How does a hidden roof sheet roll forming machine work?

A: This machine feeds metal coils through a series of rollers to shape them into roof sheets with hidden fastener profiles. The automated process ensures precise dimensions and consistent quality for large-scale production.

Q: Where can I find a reliable sheet metal roofing machine for sale company?

A: Reputable manufacturers and suppliers offer sheet metal roofing machines online or through global distributors. Look for companies with certifications, customer reviews, and after-sales support to ensure reliability.

Q: What materials can a hidden fastener metal roofing machine process?

A: These machines typically handle galvanized steel, aluminum, or pre-painted metal coils. Material compatibility depends on the machine’s design, so confirm specifications with the supplier before purchasing.

Q: What maintenance does a hidden roof sheet roll forming machine require?

A: Regular lubrication, roller cleaning, and inspection of electrical components are essential. Follow the manufacturer’s maintenance schedule to prevent downtime and extend the machine’s lifespan.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025