Feb . 18, 2025 01:36

Back to list

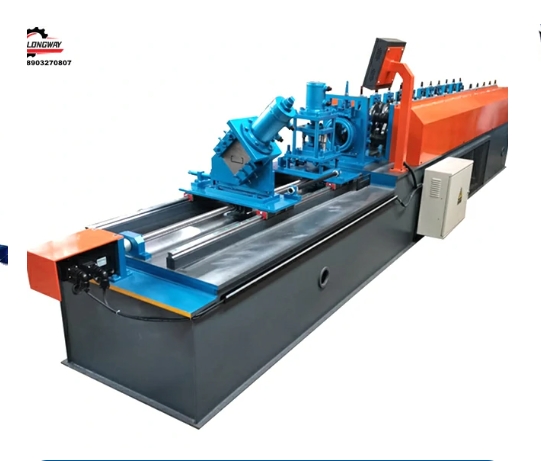

good quality pipe roll forming machine

Selecting the right pipe roll forming machine is a crucial decision for manufacturers aiming to achieve precision, efficiency, and quality. This piece of equipment is a foundation for producing high-quality pipes used across various industries. Understanding the key attributes that define a good quality pipe roll forming machine is vital for any business looking to invest wisely and ensure long-term operational success.

Trustworthiness is critical when investing in a pipe roll forming machine. This trust is built through comprehensive customer support services and warranties that go beyond the purchase itself. Manufacturers who provide training, troubleshooting, and ongoing maintenance support ensure that their clients can maximize their investment. A trustworthy manufacturer will also be transparent about the machine's capabilities and will not oversell features, ensuring that client expectations align with the machine's actual performance. Incorporating user experience into the design of a pipe roll forming machine enhances operational efficiency and ease of use. A machine that is intuitive to operate reduces the learning curve for operators, minimizing human error and maximizing productivity. User-friendly control interfaces and easy-access maintenance points improve the overall experience for those who work with the machinery daily, contributing to a more satisfied and motivated workforce. In conclusion, when selecting a pipe roll forming machine, businesses must look beyond the initial purchase price and assess the machine's ability to deliver quality, precision, and reliability. A good quality pipe roll forming machine stands as a testament to the manufacturer's expertise and authority in the industry and creates a foundation for building trust with its users. By emphasizing experience, expertise, authoritativeness, and trustworthiness, manufacturers can ensure they are investing in equipment that will support their business goals now and in the future.

Trustworthiness is critical when investing in a pipe roll forming machine. This trust is built through comprehensive customer support services and warranties that go beyond the purchase itself. Manufacturers who provide training, troubleshooting, and ongoing maintenance support ensure that their clients can maximize their investment. A trustworthy manufacturer will also be transparent about the machine's capabilities and will not oversell features, ensuring that client expectations align with the machine's actual performance. Incorporating user experience into the design of a pipe roll forming machine enhances operational efficiency and ease of use. A machine that is intuitive to operate reduces the learning curve for operators, minimizing human error and maximizing productivity. User-friendly control interfaces and easy-access maintenance points improve the overall experience for those who work with the machinery daily, contributing to a more satisfied and motivated workforce. In conclusion, when selecting a pipe roll forming machine, businesses must look beyond the initial purchase price and assess the machine's ability to deliver quality, precision, and reliability. A good quality pipe roll forming machine stands as a testament to the manufacturer's expertise and authority in the industry and creates a foundation for building trust with its users. By emphasizing experience, expertise, authoritativeness, and trustworthiness, manufacturers can ensure they are investing in equipment that will support their business goals now and in the future.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products