snap lock roof panel machine factories

The Rise of Snap Lock Roof Panel Machine Factories Revolutionizing Roofing Solutions

In recent years, the construction industry has experienced significant advancements in technology, leading to the development of innovative solutions that enhance efficiency and quality. One of the most exciting developments is the rise of snap lock roof panel machine factories. These specialized facilities are dedicated to producing snap lock roofing panels, which are increasingly popular due to their numerous advantages over traditional roofing methods. This article explores the functionality, benefits, and growth of snap lock roof panel machine factories, shedding light on their impact on the construction sector.

Understanding Snap Lock Roofing Panels

Snap lock roofing panels are a type of metal roofing system characterized by their interlocking design. These panels are engineered to snap together, creating a secure and weather-tight seal without the need for fasteners that penetrate the roofing surface. This design not only simplifies the installation process but also reduces the likelihood of leaks and enhances the overall durability of the roof.

The materials used in snap lock roofing panels are typically high-quality metals, such as steel or aluminum, which provide excellent resistance to corrosion and extreme weather conditions. This makes them an ideal choice for a variety of applications, including commercial buildings, residential homes, and industrial structures.

The Functionality of Snap Lock Roof Panel Machines

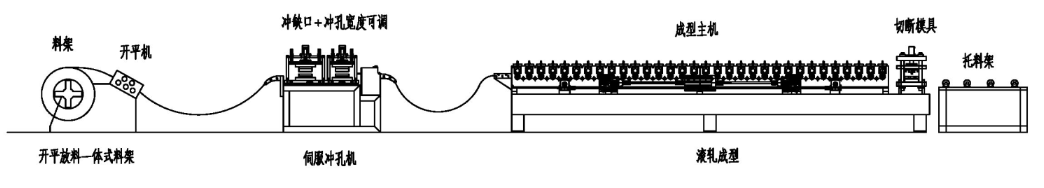

Snap lock roof panel machines are specialized equipment designed to produce these interlocking panels efficiently and accurately. These machines utilize advanced technology to cut, shape, and form metal sheets into ready-to-install panels. The automation in these machines enables manufacturers to produce large quantities of panels quickly, reducing labor costs and minimizing waste.

Moreover, these machines can be customized to produce different sizes, profiles, and designs of snap lock panels, catering to a diverse range of market needs. This flexibility allows factories to respond to specific client requirements, enhancing their competitiveness in the industry.

Benefits of Snap Lock Roofing Systems

1. Ease of Installation One of the main advantages of snap lock roofing systems is their user-friendly installation process. Since the panels snap together, there is no need for complicated fastening techniques. This not only saves time but also enables builders to complete projects more quickly, which can lead to significant cost savings.

snap lock roof panel machine factories

2. Weather Resistance Snap lock panels are designed to withstand harsh weather conditions. Their interlocking design minimizes the chances of water infiltration, while the high-quality materials resist rust and corrosion. This ensures that the roofs remain functional and aesthetically pleasing for many years.

3. Energy Efficiency Many snap lock roofing panels come with advanced insulation properties, which can contribute to improved energy efficiency in buildings. This feature helps regulate indoor temperatures and can lead to lower energy bills for homeowners and businesses alike.

4. Aesthetic Appeal With a variety of finishes and colors available, snap lock roofing panels can enhance the visual appeal of a building. This versatility allows architects and builders to achieve the desired look for their projects while maintaining the structural benefits of metal roofing.

The Growth of Snap Lock Roof Panel Machine Factories

As the demand for durable, efficient, and aesthetically pleasing roofing solutions continues to rise, so too does the growth of snap lock roof panel machine factories. These facilities are emerging worldwide, driven by the expanding construction market and the increasing popularity of metal roofing systems.

Investments in modern manufacturing technologies and automation are further propelling the growth of these factories. They play a crucial role in meeting the rising demand for snap lock roofing panels, ensuring that high-quality products are readily available to builders and contractors.

Additionally, as sustainability becomes a focal point in the construction industry, the use of metal roofing, including snap lock systems, aligns with eco-friendly practices. Metal roofs are recyclable and can be produced using less energy compared to traditional roofing materials, appealing to environmentally conscious consumers.

Conclusion

Snap lock roof panel machine factories are at the forefront of a significant transformation in the roofing industry. By providing efficient production solutions for snap lock panels, these factories not only meet the growing demand for high-quality roofing but also contribute to the overall evolution of construction technology. As more builders and homeowners recognize the numerous benefits of snap lock roofing systems, the future of these factories looks bright, promising a new era in roofing innovation.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025