roof panel roll forming machine factory

Roof Panel Roll Forming Machine Factory Revolutionizing Roofing Solutions

In the construction industry, efficiency and quality are paramount, particularly when it comes to roofing solutions. One of the innovative solutions that has emerged to meet these demands is the roof panel roll forming machine. Factories producing such machinery are at the forefront of technological advancements, providing essential tools that enhance production capabilities for roofing manufacturers.

Understanding Roof Panel Roll Forming Machines

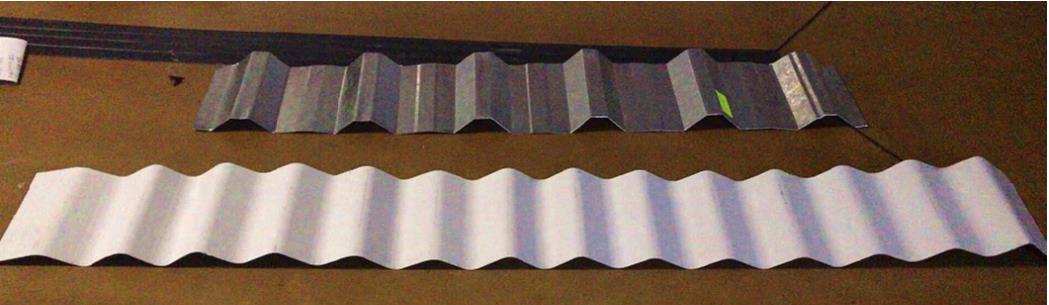

Roof panel roll forming machines are specialized equipment designed to create metal panels used in roofing applications. These machines convert flat metal sheets into specific profiles through a series of forming stations, which gradually shape the material into the desired roofing panels. The primary advantage of these machines lies in their ability to produce panels of consistent quality and at high speeds, reducing the time and labor associated with traditional roofing methods.

Key Benefits of Roof Panel Roll Forming Machines

1. Efficiency One of the most significant benefits of utilizing a roof panel roll forming machine is its efficiency. A single machine can produce large quantities of roofing panels in a relatively short amount of time. This efficiency supports contractors and builders in meeting tight deadlines without compromising on quality.

2. Cost-Effectiveness Although the initial investment in a roll forming machine may be substantial, the long-term savings are considerable. Reduced labor costs, minimized waste, and lower transportation costs (due to the ability to create panels on-site) contribute to overall savings. Additionally, the durability of the formed panels ensures that the lifespan of the roofs is extended, providing value to customers.

3. Customization Many factories offering roll forming machines allow for customization according to specific client needs. This flexibility enables manufacturers to produce various panel profiles, widths, and lengths, accommodating diverse roofing designs and preferences. Customization is especially important in meeting local building codes and aesthetic requirements.

roof panel roll forming machine factory

4. Quality Control The roll forming process inherently facilitates better quality control. Each panel is produced under uniform conditions, minimizing variability and ensuring that each piece meets stringent quality standards. Moreover, advancements in technology have led to improved monitoring systems, allowing manufacturers to detect and rectify issues in real-time.

The Role of Roof Panel Roll Forming Machine Factories

Factories dedicated to producing roof panel roll forming machines are essential in the global construction landscape. These facilities not only manufacture the machines but also provide essential services, including installation, training, and maintenance. By equipping customers with the knowledge and skills to operate these machines effectively, factories ensure that manufacturers can leverage the full potential of their investment.

Moreover, the innovation in roof panel roll forming technology continues to evolve. Increased automation, smarter control systems, and enhanced material handling techniques are being integrated into new models, making them more user-friendly and efficient. This evolution reflects the broader trends in manufacturing where Industry 4.0 principles—such as connectivity, automation, and data exchange—are becoming more prevalent.

Conclusion

The roof panel roll forming machine factory is a vital component in the modern construction ecosystem. As the demand for efficient, high-quality roofing solutions grows, these factories are well-positioned to play a key role. Through continuous innovation and a commitment to quality, they provide manufacturers with the tools necessary to thrive in a competitive market.

Investing in roof panel roll forming machines represents a strategic move for roofing manufacturers seeking to optimize their production processes. The benefits of efficiency, cost-effectiveness, customization, and quality control make these machines indispensable in today's construction landscape. As the industry evolves, so too will the technologies that support it, ensuring that roof panel roll forming machine factories remain pivotal players in the pursuit of excellence in roofing solutions.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025