rack roll forming machine

Understanding Rack Roll Forming Machines Revolutionizing Metal Fabrication

In the world of metal fabrication, efficiency and precision are paramount. One of the key technologies that have surfaced to meet these demands is the rack roll forming machine. This sophisticated machinery is designed to create various types of metal racks and profiles used in an array of applications, from industrial storage solutions to custom architectural frameworks.

What is a Rack Roll Forming Machine?

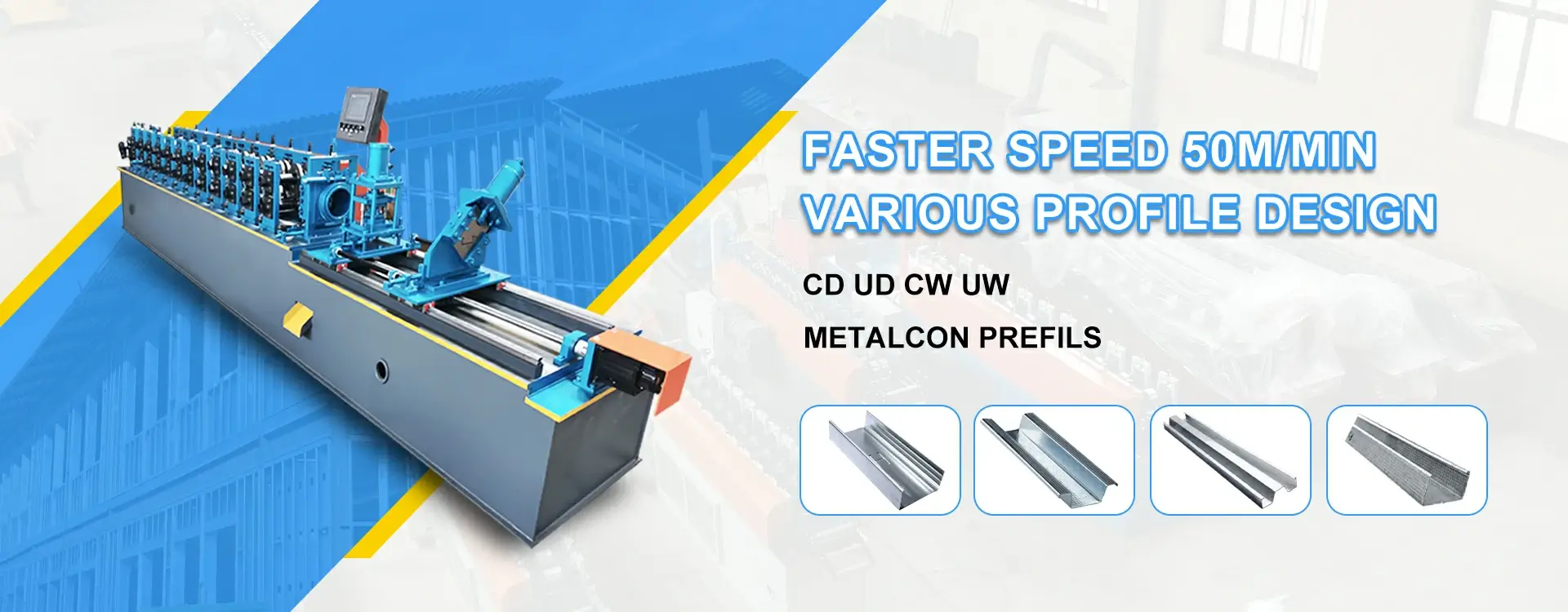

A rack roll forming machine is specialized equipment that utilizes metal sheets or strips and transforms them into specific shapes through a continuous bending process. The term roll forming refers to the method of passing the metal through a series of rollers, which gradually reshape the material until the desired profile is achieved.

The Process

The roll forming process begins with feeding a flat metal sheet into the machine. The machine has multiple sets of rollers that progressively shape the sheet as it passes through. Each set of rollers is tailored to produce a specific part of the final profile, ensuring accuracy and uniformity. The result is a continuous length of shaped metal that can be cut to the required length.

This method offers several advantages over traditional metal fabrication techniques, such as stamping or welding. For one, roll forming is a continuous process, making it more efficient for producing large quantities of the same profile. Additionally, because it reduces waste and minimizes the need for secondary operations, rack roll forming is often more cost-effective in the long run.

Applications of Rack Roll Forming Machines

rack roll forming machine

Rack roll forming machines are indispensable in various industries. The most common applications include manufacturing metal storage racks, shelving systems, and structural supports. In the retail sector, these machines are employed to create display racks and fixtures that optimize space and showcase products effectively. In the automotive industry, roll-formed components are integral to building lightweight frames that ensure vehicle efficiency and safety.

Furthermore, custom applications in the construction industry have seen an increasing utilization of rack roll forming technology. Builders and architects are leveraging these machines to produce bespoke profiles that meet specific design requirements, thereby enhancing the architectural integrity of their projects.

Advancements in Technology

With advancements in technology, modern rack roll forming machines are becoming increasingly sophisticated. Many are equipped with computer numerical control (CNC), which allows for precise adjustments and customization of profiles without extensive downtime. This technological integration enhances the versatility of the machines, enabling manufacturers to switch between designs quickly and efficiently.

Moreover, recent innovations focus on improving automation and reducing labor costs, making it easier for manufacturers to scale operations. The emergence of smart technology in manufacturing further supports real-time monitoring and maintenance, increasing reliability and reducing unexpected downtimes.

Conclusion

In conclusion, rack roll forming machines represent a significant leap forward in metal fabrication processes. Their efficiency, precision, and adaptability make them essential tools in various industries. As technology continues to advance, these machines will play an increasingly vital role in meeting the ever-growing demands for high-quality metal products. Whether in construction, automotive production, or retail, the impact of rack roll forming machines is profound, redefining the very landscape of metalworking.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025