on site roll forming companies

The Rise of On-Site Roll Forming Companies Revolutionizing Metal Fabrication

In the ever-evolving world of manufacturing and construction, on-site roll forming companies have emerged as a transformative force, revolutionizing the way metal components are produced. This innovative approach to metal fabrication offers numerous benefits that traditional methods simply cannot match, making it an increasingly popular choice for various industries.

What is On-Site Roll Forming?

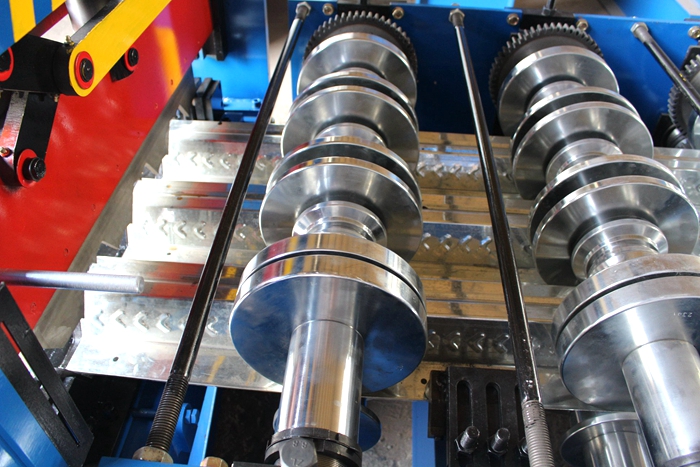

On-site roll forming is a production method where metal is formed into desired shapes and profiles directly at the construction site. By using specialized mobile equipment, companies can roll sheets of metal into beams, channels, and other components as needed. This process eliminates the need to transport pre-formed materials from a factory, reducing inventory costs and minimizing delays associated with transportation.

Advantages of On-Site Roll Forming

1. Cost-Efficiency One of the primary advantages of on-site roll forming is its cost-effectiveness. Traditional metal fabrication requires significant investments in transportation, storage, and handling. By rolling the materials on-site, companies can significantly cut these costs and allocate resources more efficiently.

2. Customization and Flexibility With on-site roll forming, companies can easily customize metal components to meet specific project needs. This flexibility allows for rapid adjustments in design without the lengthy lead times associated with traditional manufacturing. Whether it’s a unique profile or a specific length, on-site roll forming can accommodate a wide range of requirements.

3. Reduction in Waste On-site roll forming can significantly reduce material waste. Unlike traditional methods where excess materials often end up as scrap, on-site production allows for precision cutting and shaping, ensuring that only the required amount of metal is used. This not only saves money but is also more environmentally friendly.

4. Reduced Lead Times In fast-paced construction environments, time is of the essence. On-site roll forming drastically reduces lead times, allowing companies to produce and install components in a matter of hours instead of days or weeks. This speed enhances project efficiency and can lead to quicker project completions.

on site roll forming companies

5. Increased Quality Control When production occurs on-site, companies have the advantage of direct oversight and immediate quality control. This allows for real-time adjustments to production processes, ensuring that the final product meets high standards of quality and precision.

6. Enhanced Collaboration On-site roll forming fosters better collaboration among project stakeholders. Since the manufacturing occurs at the site, architects, engineers, and builders can work closely together to ensure that the components produced meet project specifications. This collaborative approach leads to improved communication and fewer errors in the construction process.

Applications of On-Site Roll Forming

On-site roll forming is versatile and applicable across various industries. In construction, it is frequently used to produce roofing systems, wall panels, and structural components for buildings. In the automotive industry, on-site roll forming can create various frame components and supports. Additionally, sectors such as HVAC and renewable energy are also reaping the benefits of this innovative manufacturing technique.

Challenges and Future Directions

While on-site roll forming has many advantages, it is not without its challenges. One potential hurdle is the need for skilled operators who can effectively manage mobile roll-forming equipment. Additionally, the initial setup of on-site manufacturing equipment requires careful planning and logistics to ensure everything runs smoothly.

Looking ahead, the future of on-site roll forming companies appears promising. As construction techniques continue to evolve, and the demand for customized metal components increases, more companies are likely to adopt this method. With advancements in technology, such as automated roll-forming machines and improved software for design and production, the efficiency and capabilities of on-site roll forming are expected to grow exponentially.

Conclusion

On-site roll forming companies are at the forefront of revolutionizing the metal fabrication industry. By offering cost-effective solutions, customization, and enhanced efficiency, these companies are changing how industries approach manufacturing and construction. As the demand for faster, more adaptable production methods rises, on-site roll forming is poised to become an indispensable part of the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025