Metal Keel Roll Forming Equipment Manufacturing Solutions for Quality Production

Understanding Metal Keel Roll Forming Machines A Comprehensive Overview

In today’s rapidly advancing manufacturing landscape, the demand for efficient and precise production methods is at an all-time high. One of the notable innovations in this field is the metal keel roll forming machine. This specialized equipment plays a critical role in producing metal keels used in various applications, such as constructing walls, ceilings, and other structural frameworks.

What is a Metal Keel Roll Forming Machine?

A metal keel roll forming machine is a type of machinery that continuously transforms flat metal sheets into specific shapes through a series of rollers. The process begins with feeding a flat steel strip into the machine, where it passes through a series of paired rollers that gradually shape the metal into a desired profile, typically resembling a “C” or “U” shape. This continuous forming process allows for high production rates with uniform quality, making it ideal for manufacturing metal keels.

Importance in Construction

Metal keels are integral components in modern construction projects. They serve as essential structural supports in lightweight partition walls and ceilings, offering stability and durability without the added weight of traditional building materials. Utilizing metal keels in construction not only enhances structural integrity but also facilitates quicker installation processes. As construction projects grow more complex, the need for efficient materials like metal keels becomes increasingly vital.

Key Features of a Metal Keel Roll Forming Machine

1. High Precision The roll forming process ensures that the metal keels produced are consistent in dimensions, making them ideal for precise construction applications. 2. Customization Many manufacturers offer customizable options for their roll forming machines, allowing businesses to produce different profiles and sizes based on specific project requirements.

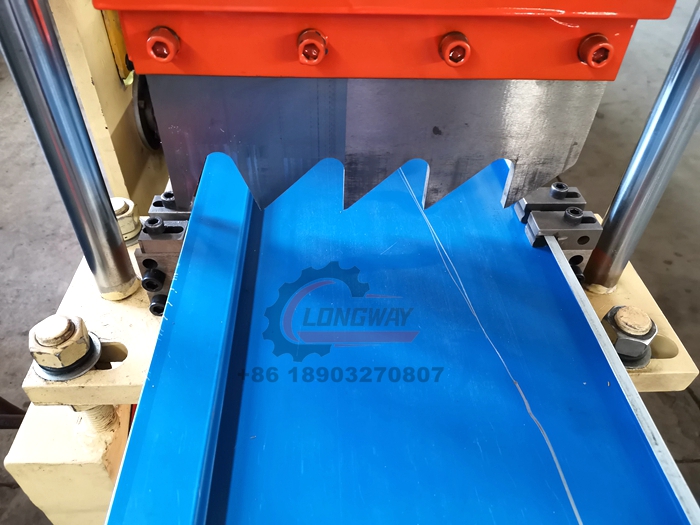

metal keel roll forming machine factory

3. Automated Controls Modern metal keel roll forming machines often come equipped with advanced digital controls, improving ease of operation and reducing the likelihood of human error.

4. Efficiency These machines are designed for high-speed production, capable of producing large quantities within a short time frame, thus meeting the demands of busy construction schedules.

Selecting the Right Factory

When looking for a metal keel roll forming machine, choosing a reputable manufacturer or factory is crucial. A reliable factory should have a proven track record in producing high-quality machinery that complies with international standards. Additionally, potential buyers should consider factors such as customer support, warranty, and available after-sales service.

Moreover, assessing the factory's development and innovation capabilities is important. A manufacturer that invests in research and development is more likely to provide machines that incorporate the latest technology, thereby enhancing performance and reliability.

Conclusion

The metal keel roll forming machine is a significant asset in the manufacturing and construction industries. By using this technology, businesses can improve their production efficiency, ensure product quality, and meet the growing needs of modern architecture. As the demand for lightweight and robust construction materials continues to rise, investing in a high-quality metal keel roll forming machine from a reputable factory is a smart move for any construction-related enterprise. Embracing this technology not only leads to enhanced productivity but also plays a vital role in the evolution of construction methodologies in a highly competitive market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025