Factory for Custom Manual Roll Forming Machines with Precision Engineering

Manual Roll Forming Machine A Comprehensive Overview

The world of manufacturing is continuously evolving, with various technologies emerging to optimize production processes. Among these technologies is the manual roll forming machine, an essential tool in the metalworking industry that offers versatility and efficiency. This article will explore the functionality, benefits, and considerations of manual roll forming machines, while also shedding light on the factories and processes involved in their production.

What is a Manual Roll Forming Machine?

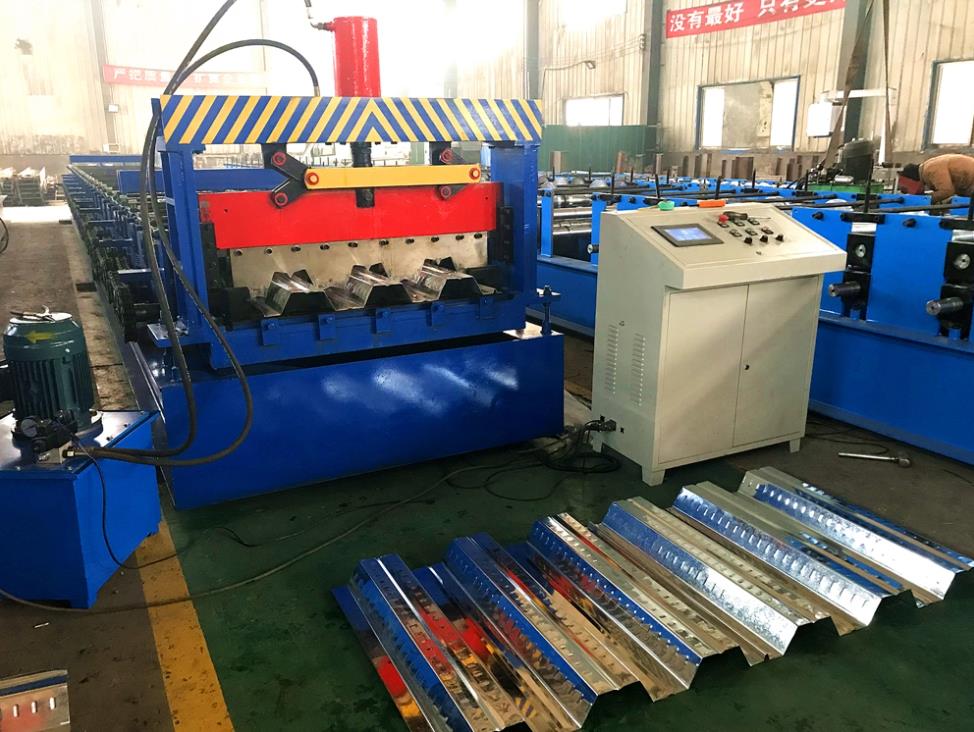

A manual roll forming machine is a device used for shaping metal into specific profiles through a series of rollers. This process involves feeding a flat strip of metal into the machine, where it is progressively shaped as it passes through multiple sets of rollers. The complexity of the desired profile dictates the number of rollers used in the machine. Manual roll forming machines are particularly advantageous for producing small batches of metal components where manual operation allows for flexibility.

How Does a Manual Roll Forming Machine Work?

The operation of a manual roll forming machine is relatively straightforward. The operator manually feeds the metal strip into the machine, ensuring it aligns correctly with the initial roller set. As the metal passes through each subsequent roller, it is gradually shaped into the desired profile. While the initial setup may require precision to calibrate the rollers properly, once it is correctly configured, the machine can produce successive pieces efficiently.

One of the key aspects of manual roll forming machines is their design. These machines often come with adjustable features, allowing operators to modify the profile's dimensions without needing extensive reconfiguration. This adaptability is vital for small factories or workshops that handle diverse production requirements.

Benefits of Manual Roll Forming Machines

manual roll forming machine factory

2. Flexibility The ability to easily change the roller settings permits manufacturers to produce various profiles without significant downtime. This flexibility is invaluable for bespoke orders or prototype development.

3. Reduced Labor Costs While manual roll forming machines require operators, the labor costs are typically lower than maintaining a fully automated production line. This aspect understands the budget constraints of small and medium enterprises.

4. Simplicity The straightforward design and operation of manual roll forming machines make them easy to use, even for individuals with limited experience in metalworking.

5. Quality Control Manual operation allows for closer supervision of the production process, enabling quick adjustments to ensure that the end product meets quality standards.

Considerations When Choosing a Manual Roll Forming Machine

When selecting a manual roll forming machine, several factors should be considered. The first is the range of profiles you wish to produce. Machines vary in terms of the width and thickness of the materials they can handle, so it is essential to choose one that meets your specific needs.

Furthermore, consider the machine's durability and the quality of materials used in its construction. Investing in a machine that stands the test of time will invariably save costs in the long run. Lastly, ensure that the factory producing the machine has a solid reputation for quality and service, as post-purchase support can be crucial for troubleshooting and maintenance.

Conclusion

Manual roll forming machines play a pivotal role in metal fabrication, providing an effective solution for producing custom profiles at a lower cost. Their flexibility, ease of use, and ability to deliver high-quality products make them popular among small and medium-sized manufacturers. By understanding their functionality and benefits, businesses can make informed decisions that enhance their production capabilities and meet market demands efficiently.

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025