highway guardrail making machine factory

The Highway Guardrail Making Machine Factory A Pillar of Road Safety

In the ever-evolving landscape of transportation, the safety of our roads is paramount. Among the numerous safety measures in place, highway guardrails are a critical component. To support the production of these essential structures, the highway guardrail making machine factory has emerged as a vital player in the manufacturing and engineering sectors, ensuring that robust, reliable guardrails are accessible to maintain road safety standards.

The Importance of Highway Guardrails

Highway guardrails serve a fundamental purpose in protecting vehicles and their occupants from hazards. They are designed to prevent vehicles from veering off the road, which can lead to serious accidents, fatalities, or damage to property. These barriers absorb impact, redirect vehicles, and mitigate the severity of collisions. Given the sheer volume of traffic on highways, the demand for durable and efficient guardrails has never been greater, making the factories that produce them crucial.

Manufacturing Processes at the Factory

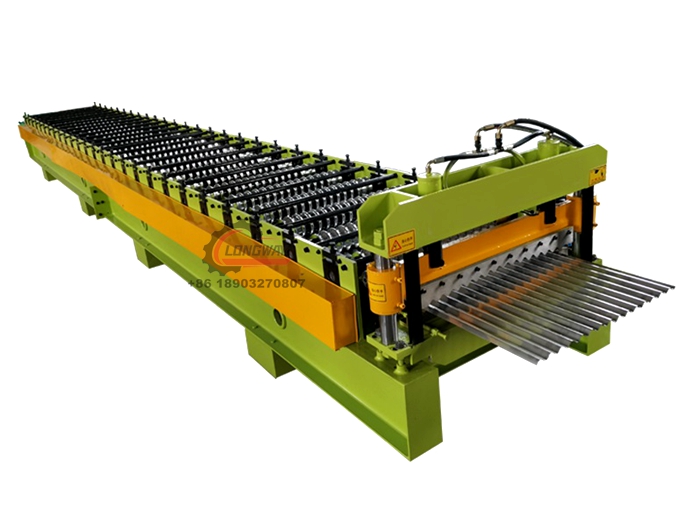

The highway guardrail making machine factory employs advanced technology and innovative methodologies to produce a variety of guardrails. The production process typically begins with the selection of high-quality raw materials, primarily galvanized steel, to ensure durability and resistance to corrosion. This selection is vital in regions prone to harsh weather conditions.

Once the materials are chosen, they undergo several transformation processes, including cutting, bending, and welding. These processes can be efficiently handled by state-of-the-art machinery designed specifically for guardrail production. Automated systems enhance precision and speed, reducing manufacturing time while improving quality control.

One of the unique features of the guardrail making machine is its versatility. Factories can produce different types of guardrails, including W-beam and Thrie-beam models, depending on the design requirements of the highway in question. This flexibility allows for customization to meet local standards and safety regulations, ensuring that every product is fit for purpose.

Advanced Technology in Production

highway guardrail making machine factory

In addition to traditional manufacturing techniques, modern highway guardrail making machine factories are increasingly incorporating cutting-edge technologies, such as Computer Numerical Control (CNC) machines, robotic welders, and automated inspection systems. These innovations enhance the precision of production and guarantee consistent quality in the final products.

For instance, CNC machines allow for intricate designs and perfect cuts that might be challenging to achieve manually. Similarly, robotic welders deliver uniform welds, contributing to the strength and longevity of the guardrails. Inspecting the products using automated systems ensures that any inconsistencies are detected early, minimizing waste and maximizing efficiency.

Environmental Considerations

As the world shifts its focus towards sustainability, the highway guardrail making machine factory is also integrating environmentally friendly practices into its operations. Recycling scrap metal from the production process, reducing energy consumption through optimized machinery, and using eco-friendly coatings are just a few examples of how these factories are working towards a greener future.

By incorporating sustainable practices, these factories not only contribute to the conservation of resources but also address growing concerns about environmental impacts. This approach resonates with consumers and governments alike, fostering a positive image for the industry.

The Future of Highway Guardrail Production

With the continuous growth of urbanization and increased vehicle usage, the need for efficient and reliable highway guardrails will only intensify. As such, the highway guardrail making machine factory will play a pivotal role in shaping road safety standards in the future. Continued investments in research and development will further enhance production capabilities, ensuring that these facilities can respond to changing demands and technological advancements.

In conclusion, the highway guardrail making machine factory stands as a cornerstone of transportation safety. By producing high-quality guardrails through advanced manufacturing techniques and environmentally friendly practices, these factories not only protect lives on the road but also contribute to the broader goals of sustainability and innovation within the industry. As we look to the future, the ongoing evolution of these factories promises to enhance road safety and improve infrastructure resilience across the globe.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025