Affordable Roll Forming Equipment for Metal Siding Production Solutions

The Advantages of Cheap Metal Siding Roll Forming Machines

In today's construction industry, the demand for durable, cost-effective building materials has risen significantly. Among the many options available, metal siding stands out due to its reliability and aesthetic appeal. However, the initial investment for high-quality metal siding can be prohibitive for many. This is where cheap metal siding roll forming machines come into play, offering a cost-effective solution for both manufacturers and builders.

What is a Roll Forming Machine?

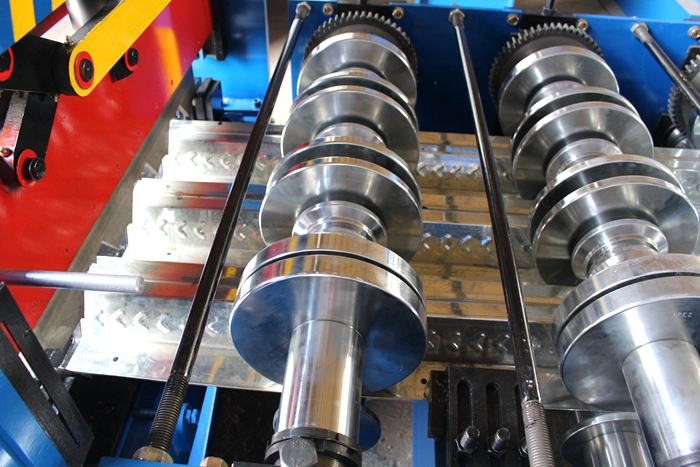

A roll forming machine is a tool used to create long lengths of metal profiles by passing a metal strip through a series of rollers. This process shapes the metal into predetermined forms, which can then be used for various construction applications, including siding, roofing, and fencing. Metal siding roll forming machines specifically cater to the production of metal siding panels, enabling the creation of customized designs tailored to individual project requirements.

Cost-Efficiency of Cheap Metal Siding Roll Forming Machines

One of the most significant advantages of investing in a cheap metal siding roll forming machine is the immediate cost savings. Traditional methods of sourcing metal siding often involve high costs associated with purchasing pre-manufactured sheets. In contrast, using a roll forming machine allows manufacturers and builders to produce metal siding on-site, which reduces transportation costs and minimizes waste. As a result, builders can offer competitive pricing to their clients while maintaining healthy profit margins.

Flexibility and Customization

Cheap metal siding roll forming machines provide unparalleled flexibility when it comes to customization. With the capability to adjust the design and size of metal siding profiles, manufacturers can respond swiftly to market demands or specific client requests. This adaptability is crucial in a construction environment where trends and requirements can change rapidly. Whether it's a specific thickness, finish, or color, roll forming machines can easily accommodate various specifications without the need for extensive retooling.

cheap metal siding roll forming machine

Enhanced Quality Control

When metal siding is produced in-house using a roll forming machine, businesses gain greater control over the quality of the materials. By overseeing the entire manufacturing process, manufacturers can ensure that the siding meets their exact standards and specifications. This enhanced quality control not only leads to a higher-quality final product but also reduces the potential for defects and the need for costly rework. With fewer deviations and consistent quality, builders can enhance their reputation for reliability and excellence.

Faster Production Times

Time is money in the construction industry. Cheap metal siding roll forming machines significantly reduce production times, allowing for quicker turnaround on projects. Traditional methods of sourcing metal siding can lead to delays in delivery and logistics challenges, which can be detrimental to project timelines. In contrast, having the capability to produce siding on-site means that builders can start projects faster and meet tight deadlines, thereby improving overall efficiency.

Sustainability and Waste Reduction

The industrial sector is under increasing pressure to adopt sustainable practices. Cheap metal siding roll forming machines contribute to sustainability efforts by minimizing waste. Since metal can be recycled, any excess material generated during the roll-forming process can be collected and reused. This approach not only conserves resources but also aligns with growing consumer preferences for environmentally friendly products.

Conclusion

The benefits of cheap metal siding roll forming machines are manifold. From cost efficiency and flexibility to enhanced quality control and faster production times, these machines represent a practical investment for builders and manufacturers alike. As the construction industry continues to evolve, adopting innovative solutions such as roll forming machines will be crucial for staying competitive and meeting the diverse needs of clients. In summary, for those looking to capitalize on the advantages of metal siding while keeping costs manageable, investing in a cheap metal siding roll forming machine is undoubtedly a wise decision.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025